Glass powder, positive electrode silver paste prepared therefrom and solar battery

A technology of glass powder and positive electrode, applied in the field of solar cells, can solve the problems of photoelectric conversion efficiency and pulling force contradiction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

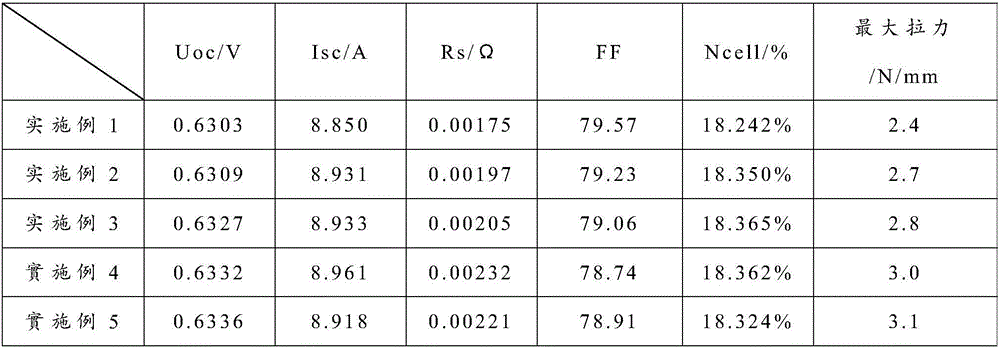

Examples

preparation example Construction

[0025] A kind of preparation method of above-mentioned glass powder, it comprises the steps:

[0026] Step S1: PbO, Bi 2 o 3 , TeO 2 , SiO 2 、WO 3 , ZnO, CaO, MgO, Al 2 o 3 , Li 2 O, Na 2 O, Fe 2 o 3 , B 2 o 3 and BaO and other oxides are mixed evenly according to the predetermined ratio and added to the platinum crucible.

[0027] Step S2: Put the above-mentioned platinum crucible filled with oxides into a high-temperature sintering furnace, sinter at a temperature of 800-1200° C., and keep it warm for 0.5-2 hours to obtain molten glass.

[0028] Step S3: Quenching the molten glass to form amorphous glass particles.

[0029] Step S4: Put the above glass particles in a ball mill for ball milling to obtain glass powder with a median particle size ranging from 0.5 μm to 3 μm.

[0030] It can be understood that in the step S1, various salts or fluorides that can be decomposed into corresponding oxides can also be used instead of the oxides.

[0031] A positive elec...

Embodiment 1

[0048] In the present embodiment, glass frit is made of PbO, Bi 2 o 3 , TeO 2 , SiO 2 、WO 3 , ZnO, CaO, MgO, Al 2 o 3 , Li 2 O, Na 2 O, Fe 2 o 3 , B 2 o 3 And BaO prepared.

[0049] Among them, the mass percentage of PbO is 30%, TeO 2 The mass percentage content is 31%, Bi 2 o 3 The mass percentage content is 22%, SiO 2 The mass percentage content of ZnO is 7%, the mass percentage content of ZnO is 2%, Na 2 The mass percentage of O is 1%, Li 2 The mass percentage of O is 1.5%, Al 2 o 3 The mass percentage of CaO is 1%, the mass percentage of CaO is 0.5%, B 2 o 3 The mass percentage content is 1%, Fe 2 o 3 The mass percentage content of BaO is 0.5%, the mass percentage content of BaO is 0.5%, the mass percentage content of MgO is 0.5%, WO 3 The mass percent content is 1.5%.

Embodiment 2

[0051] In the present embodiment, glass frit is made of PbO, Bi 2 o 3 , TeO 2 , SiO 2 、WO 3 , ZnO, CaO, MgO, Al 2 o 3 , Li 2 O, Na 2 O, Fe 2 o 3 , B 2 o 3 And BaO prepared.

[0052] Among them, the mass percentage of PbO is 27%, TeO 2 The mass percentage content is 28%, Bi 2 o 3 The mass percentage content is 26%, SiO 2 The mass percentage content of ZnO is 7.5%, the mass percentage content of ZnO is 2.5%, Na 2 The mass percentage of O is 1%, Li 2 The mass percentage of O is 1.5%, Al 2 o 3 The mass percentage of CaO is 1%, the mass percentage of CaO is 0.5%, B 2 o 3 The mass percentage content is 1%, Fe 2 o 3 The mass percentage content of BaO is 0.5%, the mass percentage content of BaO is 0.5%, the mass percentage content of MgO is 0.5%, WO 3 The mass percent content is 2.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com