A kind of preparation method of ambroxol hydrochloride impurity standard substance

A technology for ambroxol hydrochloride and a standard product, applied in the field of medicine, can solve problems such as synthesis and content calibration methods that have not been reported, and achieve control of the quality of ambroxol hydrochloride raw materials and preparations thereof, the raw materials are cheap and easy to obtain, and the preparation process is simple and convenient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

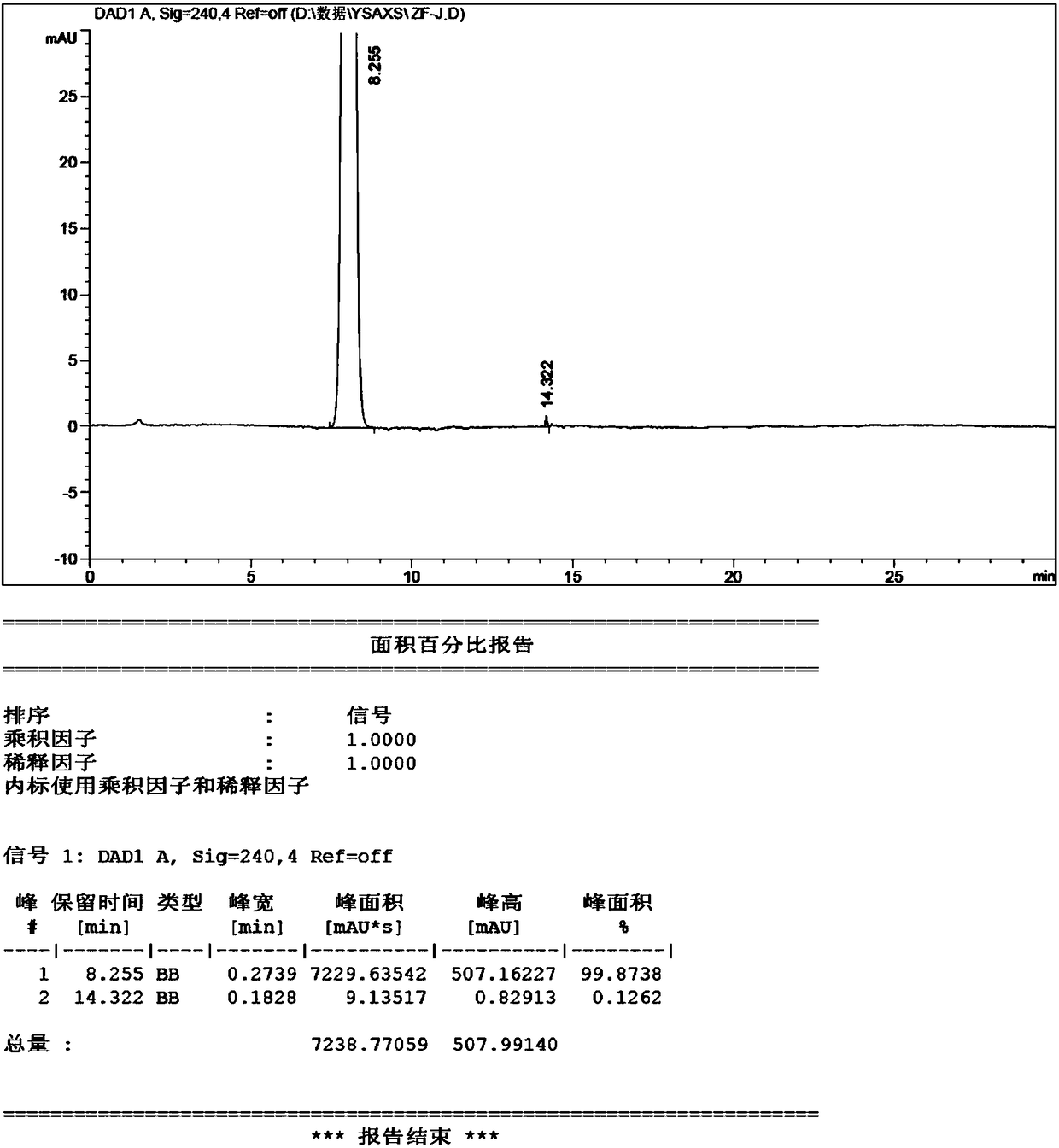

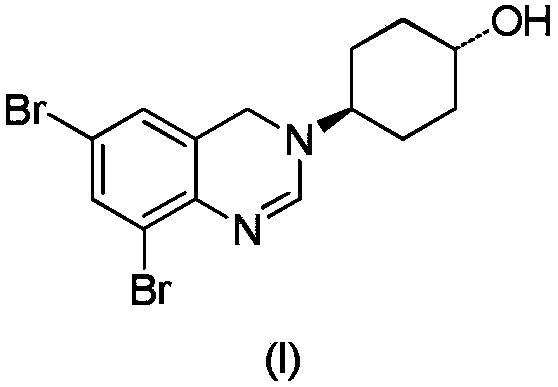

[0045] The preparation method of ambroxol hydrochloride impurity standard substance in the present embodiment is as follows:

[0046] 1. Disperse 8g (19.28mmol) of ambroxol hydrochloride in 100ml of water, add sodium hydroxide solution to adjust the pH value to 10, then add 200ml of ethyl acetate, extract, wash the extract with water, concentrate the organic phase to obtain an oily liquid, add formic acid 50ml of isopropyl ester, reflux and stir for 6h, stir to cool down to 0-5°C, keep stirring for 3h, filter, and dry the solid at 50-60°C for 4h under reduced pressure to obtain 4-(6,8-dibromo-3,4- Dihydroquinazolin-3-yl)-cyclohexanol crude product 6.9g, yield 92.12%.

[0047] 2. Add 100ml of isopropanol to 6.8g of crude product, heat and stir at 80-100°C to dissolve, filter while hot, cool the filtrate to -5-0°C, stir and crystallize for 4 hours, filter, wash the filter cake with an appropriate amount of isopropanol, The solid was dried under reduced pressure at 50-60°C for 5...

Embodiment 2

[0058] The preparation method of ambroxol hydrochloride impurity standard substance in the present embodiment is as follows:

[0059] 1. Disperse 10 g (24.12 mmol) of ambroxol hydrochloride in 100 ml of water, add sodium carbonate solution to adjust the pH value to 10, then add 200 ml of ethyl acetate, extract, wash the extract with water, concentrate the organic phase to obtain an oily liquid, add formic acid 50ml of butyl ester, stirred and reacted at 100°C for 5h, stirred and cooled to 0-5°C, kept stirring for 4h, filtered, and the solid was dried under reduced pressure at 50-60°C for 5h to obtain 4-(6,8-dibromo-3,4 -Dihydroquinazolin-3-yl)-cyclohexanol crude product 8.6g, yield 91.88%.

[0060] 2. Add 80ml of ethanol to 8g of crude product, heat and stir at 80°C to dissolve, filter while hot, cool the filtrate to -5~0°C, stir and crystallize for 4h, filter, wash the filter cake with an appropriate amount of ethanol, and decompose the solid at 50~60°C Dry under pressure fo...

Embodiment 3

[0065] The preparation method of ambroxol hydrochloride impurity standard substance in the present embodiment is as follows:

[0066] 1. Disperse 12g (28.95mmol) of ambroxol hydrochloride in 100ml of water, add sodium carbonate to adjust the pH to 9, then add 200ml of ethyl acetate, extract, wash the extract with water, concentrate the organic phase to obtain an oily liquid, add n-butyl formate 50ml, stirred and reacted at 100°C for 5h, stirred and cooled to 0-5°C, kept stirring for 5h, filtered, and the solid was dried under reduced pressure at 50-60°C for 6h to obtain 4-(6,8-dibromo-3,4-di Hydroquinazolin-3-yl)-cyclohexanol crude product 10.4g, yield 92.86%.

[0067] 2. Add 110ml of n-butanol to 10g of crude product, heat and stir at 80°C to dissolve, filter while hot, cool the filtrate to -5~0°C, stir and crystallize for 3h, filter, wash the filter cake with an appropriate amount of ethanol, and the solid is at 50~60 After drying under reduced pressure at ℃ for 4 hours, 9....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com