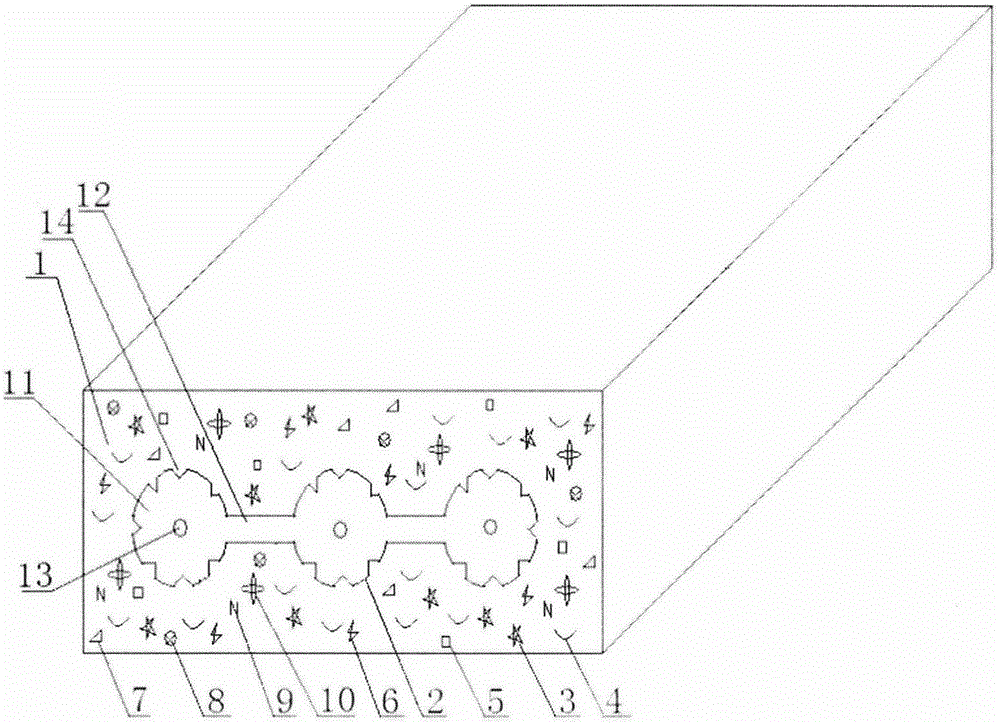

Internally-enhanced lightweight composite plate and production method thereof

A composite material and wood-plastic composite material technology, which is applied to the field of internally reinforced lightweight composite material boards and their preparation, can solve the problems of shortening the service life, limiting the scope of use, affecting the use effect, etc., so as to reduce the emission and save the use of materials. The effect of less quantity and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

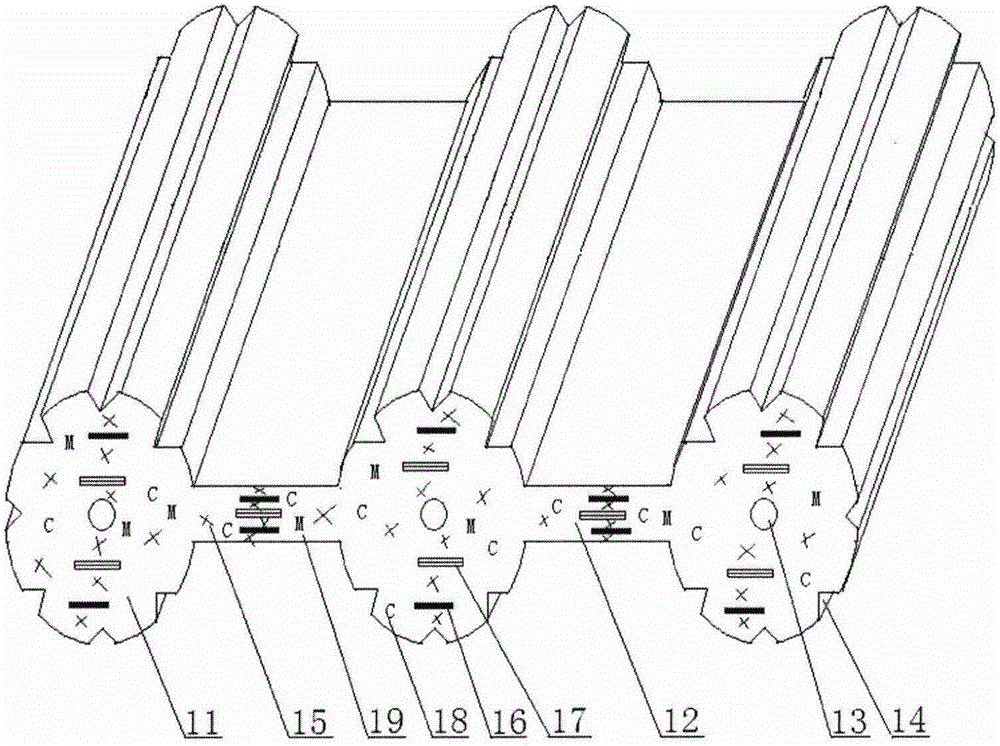

[0041] Embodiment 1: A kind of preparation method of internal reinforcement lightweight composite material plate, its preparation process is:

[0042] (1) Put 100 parts by mass of plastic particles (the mass content of high-density polyethylene is 85%) on the roller of the calender preheated to 160 ° C until it is completely melted, then add 50 parts by mass of three Ethylene-propylene rubber (the mass content of propylene is 48%), after kneading with the plastic melt for 25 minutes, remove the mixture, cool to room temperature, and crush it into modified plastic particles with a particle size of less than 5 mm;

[0043] (2) Prepare the forming mold of the inner reinforcing layer of the hollow glass fiber reinforced plastics, apply a release agent, and set aside;

[0044] (3) take by weighing the unsaturated polyester resin of 100 mass parts, the nylon cloth of 10 mass parts (unit weight is 220g / m 2 ), 30 parts by mass of glass fiber cloth (unit weight is 400g / m 2 ), 1 mass pa...

Embodiment 2

[0050] Embodiment 2: A kind of preparation method of internal reinforcement lightweight composite material plate, its preparation process is:

[0051] (1) Put 100 parts by mass of plastic particles (the mass content of high-density polyethylene is 75%) on the roller of the calender preheated to 150 ° C until it is completely melted, then add 40 parts by mass of three Ethylene-propylene rubber (the mass content of propylene is 43%), after kneading with the plastic melt for 20 minutes, remove the mixture, cool to room temperature, and crush it into modified plastic particles with a particle size of less than 5mm;

[0052] (2) Prepare the forming mold of the inner reinforcing layer of the hollow glass fiber reinforced plastics, apply a release agent, and set aside;

[0053] (3) take by weighing the unsaturated polyester resin of 100 mass parts, the nylon cloth of 5 mass parts (unit weight is 180g / m 2 ), 20 parts by mass of glass fiber cloth (unit weight is 300g / m 2 ), 0.8 parts...

Embodiment 3

[0059] Example 3: A method for preparing an internally reinforced lightweight composite material plate, the preparation process of which is:

[0060] (1) Put 100 parts by mass of plastic particles (the mass content of high-density polyethylene is 95%) on the roller of the calender preheated to 170 ° C until it is completely melted, then add 60 parts by mass of three Ethylene-propylene rubber (the mass content of propylene is 53%), after kneading with the plastic melt for 30 minutes, remove the mixture, cool to room temperature, and crush it into modified plastic particles with a particle size of less than 5 mm;

[0061] (2) Prepare the forming mold of the inner reinforcing layer of the hollow glass fiber reinforced plastics, apply a release agent, and set aside;

[0062] (3) take by weighing the unsaturated polyester resin of 100 mass parts, the nylon cloth of 15 mass parts (unit weight is 260g / m 2 ), 40 parts by mass of glass fiber cloth (unit weight is 500g / m 2 ), 1.2 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com