Method for extracting polypeptide from vinasse

A technology of distiller's grains and water-soluble protein, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low yield of polypeptides, achieve the effect of improving the effect of enzymatic hydrolysis, ensuring the yield, and avoiding bondage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

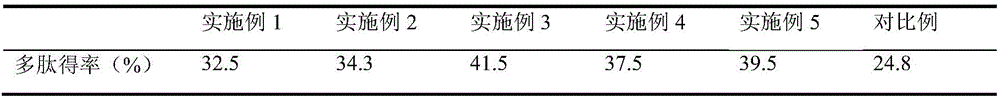

Examples

Embodiment 1

[0059] Step 1. The wet distiller's grains are vacuum freeze-dried and crushed.

[0060] Step two, degreasing. Use organic solvent cleaning (such as acetone) to clean the above-mentioned crushed residue 2-3 times, and then air dry.

[0061] Step 3: Extraction of water-soluble protein. The vinasse is dissolved in an ethanol alcohol aqueous solution with a mass fraction of 80 wt% in lye, the lye is added to maintain the pH at 13, and the solid is settled by centrifugal separation to obtain a filtrate. Then the filtrate was concentrated to 10% of the original volume with a 600-mesh filter membrane, then acid was added to adjust its pH to 6, and a 600-mesh filter membrane was used to filter to obtain solid components; the solid components were dissolved in water, and then Centrifuge and dry the solid phase.

[0062] Step 4. The above solids are added to the fermenter, and the volume ratio of Trichoderma reesei is 1:0.5:3:1 (the number of viable bacteria is 3×10). 10 fu / ml), Bacillus am...

Embodiment 2

[0067] Step 1. The wet distiller's grains are vacuum freeze-dried and crushed.

[0068] Step two, degreasing. Use organic solvent cleaning (such as acetone) to clean the above-mentioned crushed residue 2-3 times, and then air dry.

[0069] Step 3: Extraction of water-soluble protein. The vinasse is dissolved in an ethanol alcohol aqueous solution with a mass fraction of 50 wt% in lye, the lye is added to maintain the pH at 8, and the solid is settled by centrifugal separation to obtain a filtrate. Then the filtrate was concentrated to 5% of the original volume with a 400-mesh filter membrane, then acid was added to adjust its pH to 2, and then filtered with a 40,000-mesh filter membrane to obtain solid components; the solid components were dissolved in water, and then Centrifuge and dry the solid phase.

[0070] Step 4. The above solids are added to the fermentor, and the volume ratio of Trichoderma reesei is 1:0.8:3:1 (the number of viable bacteria is 5×10). 10 fu / ml), Bacillus a...

Embodiment 3

[0075] Step 1. The wet distiller's grains are vacuum freeze-dried and crushed.

[0076] Step two, degreasing. Use organic solvent cleaning (such as acetone) to clean the above-mentioned crushed residue 2-3 times, and then air dry.

[0077] Step 3: Extraction of water-soluble protein. The vinasse is dissolved in an ethanol alcohol aqueous solution with a mass fraction of 60 wt% in lye, the lye is added to maintain the pH at 10, and the solid is settled by centrifugal separation to obtain a filtrate. Then the filtrate was concentrated to 10% of the original volume using a 400-mesh filter membrane, then acid was added to adjust its pH to 2, and a 400-mesh filter membrane was used to filter to obtain solid components; the solid components were dissolved in water, and then Centrifuge and dry the solid phase.

[0078] Step 4. The above solids are added to the fermentor, and the volume ratio of Trichoderma reesei is 1:0.8:3:2 (the number of viable bacteria is 5×10). 10 fu / ml), Bacillus a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com