Self-controlled type self-absorption centrifugal pump for ship

A centrifugal pump, marine technology, applied in the field of self-controlled marine self-priming centrifugal pump, can solve the problems of large installation area of the pump, low pump operation efficiency, unsuitable for ships, etc., to reduce the back flow in the pump, run The effect of high efficiency and easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

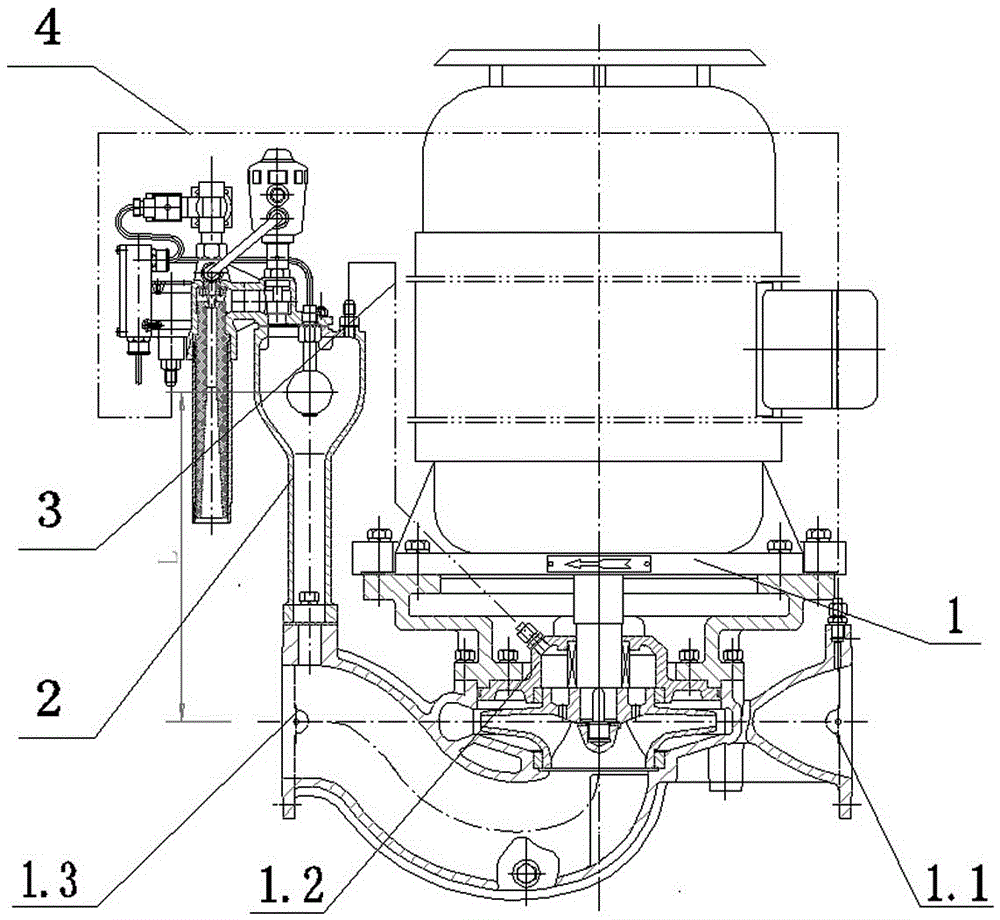

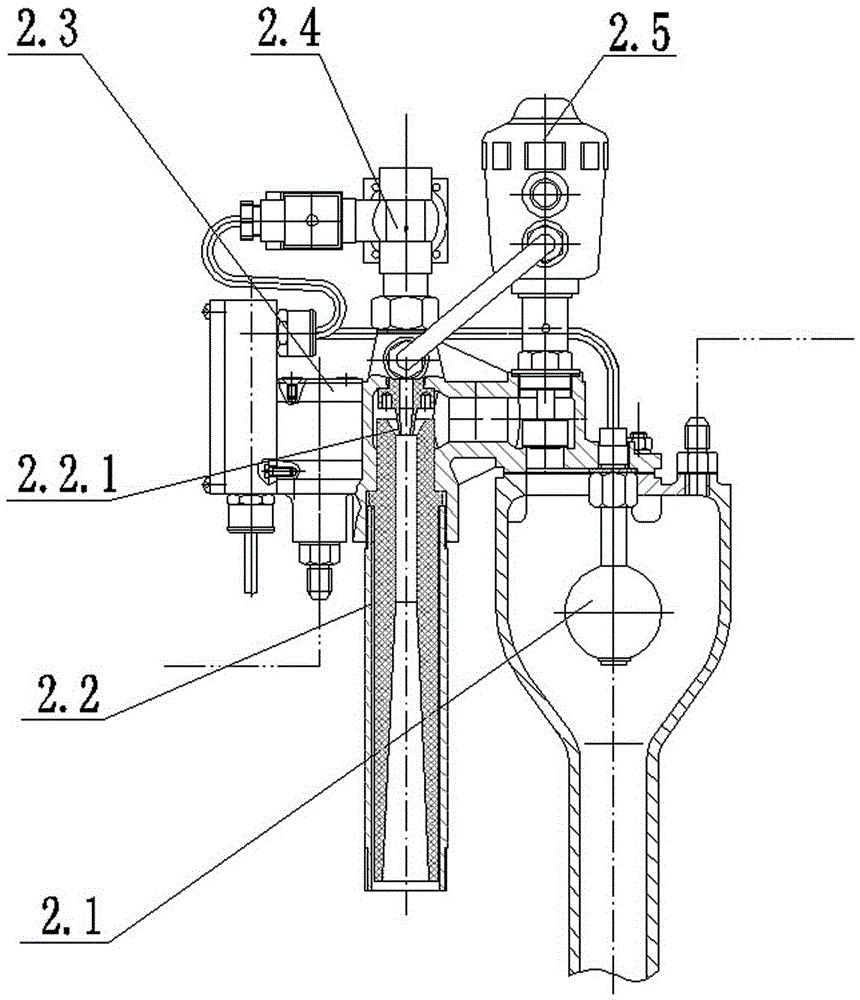

[0015] figure 1 The self-controlled self-priming centrifugal pump shown is a combined device, which includes a centrifugal pump 1 , a suction device 2 , a pressure control pipeline 4 and a suction pipeline 3 . Wherein the centrifugal pump 1 is the main part, because this embodiment is applied on the ship, must choose the marine vertical pump that accords with the supporting specification of the ship as the matching pump. The water inlet 1.3 and the water outlet 1.1 of the vertical centrifugal pump 1 are separated on both sides, and the flanges of the water inlet 1.3 and the water outlet 1.1 are provided with upward radial external interfaces, and the pump casing 1.2 is also provided with external interfaces. The present invention overlaps the vertical suction device 2 with a radially outer interface on the flange side of the water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com