Method for automatically capturing microball in optical tweezer system

An automatic capture and microsphere technology, which is applied to capture objects visible under the microscope, acquire/recognize the direction of microscopic objects, instruments, etc., can solve the problems of not many, limited observation field of view and depth of field, difficulty in capturing particles, etc., and achieve improved stability performance, improve capture efficiency, and eliminate hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

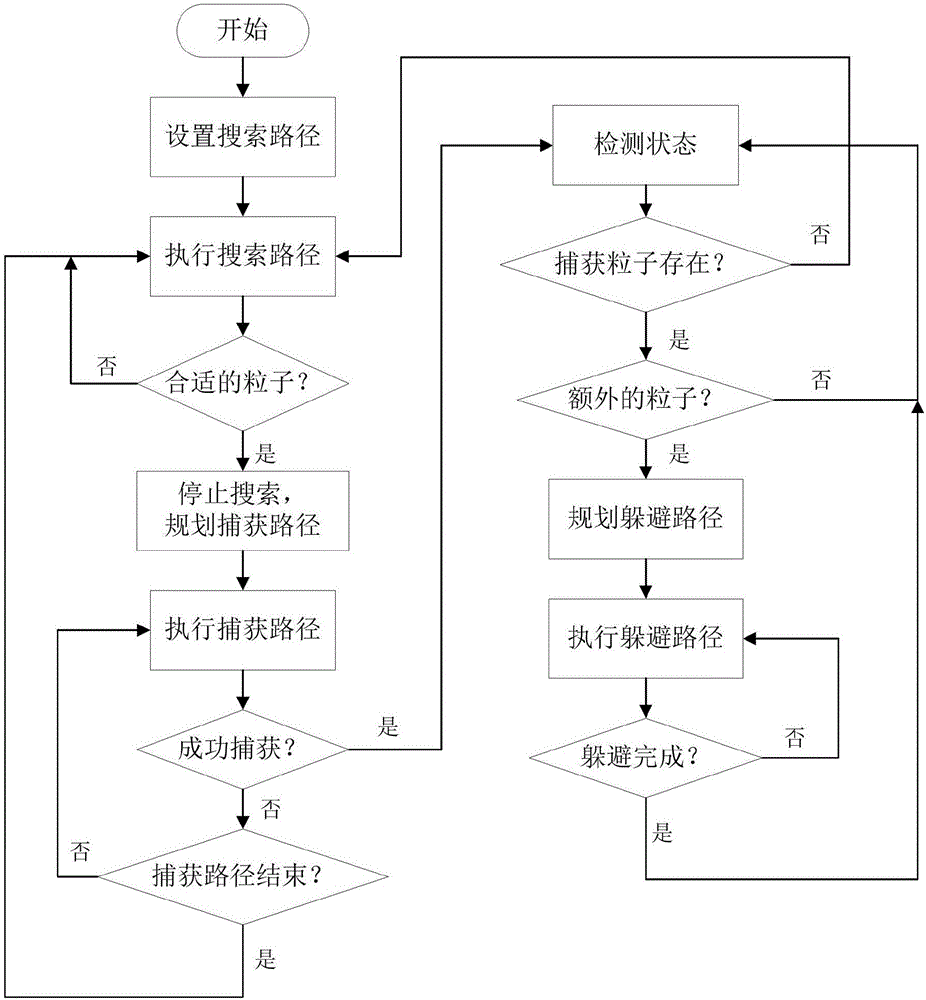

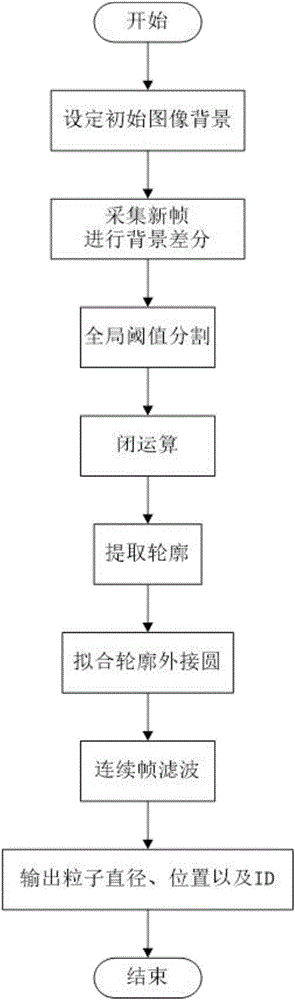

[0042] The method for automatically capturing microspheres based on the optical tweezers system of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

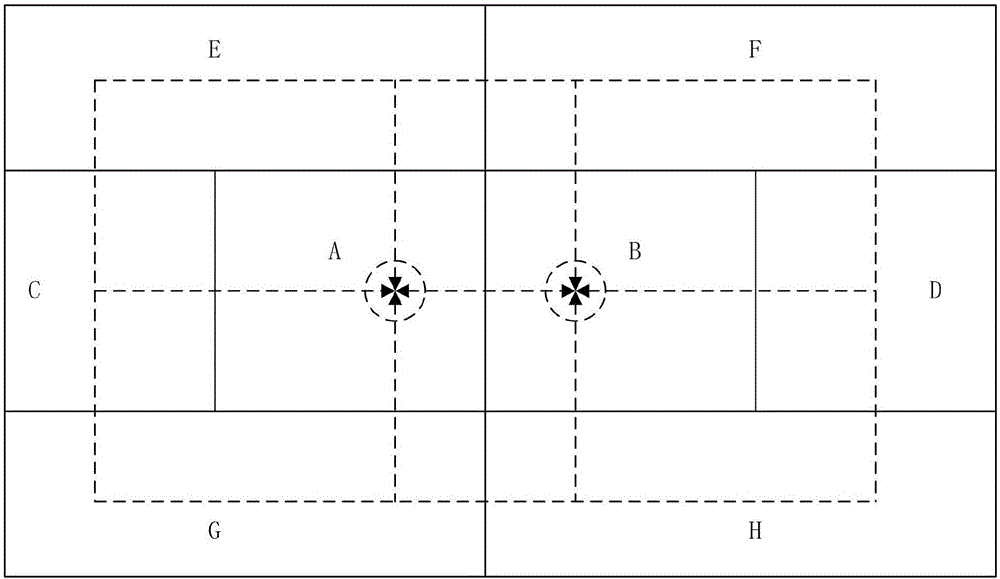

[0043] The test system for this method uses Figure 4 The shown dual optical tweezers system includes a dual optical tweezers generation module, an illumination module, an image acquisition module and a stage control module. The dual optical tweezers generation module adopts single laser (1064nm) beam splitting and high numerical aperture objective lens to converge to generate light traps; the illumination module adopts transmission type coaxial uniform illumination, the illumination light source adopts LED with a wavelength of 780nm, and the illumination optical path and the main optical path adopt dichroism The imaging module uses the DCC1545M COMS camera of Thorlabs in the United States, and the sample displacement platform uses the piezoelectric controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com