Device and method for preparing nanotip transfer pipette

A nano-tip and pipette technology, applied in the field of nano-processing, can solve the problems of inability to obtain small or very small sizes, large capillary size, and inability to manufacture, and achieve simple preparation methods and systems, high sensitivity, and easy The effect of mastering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

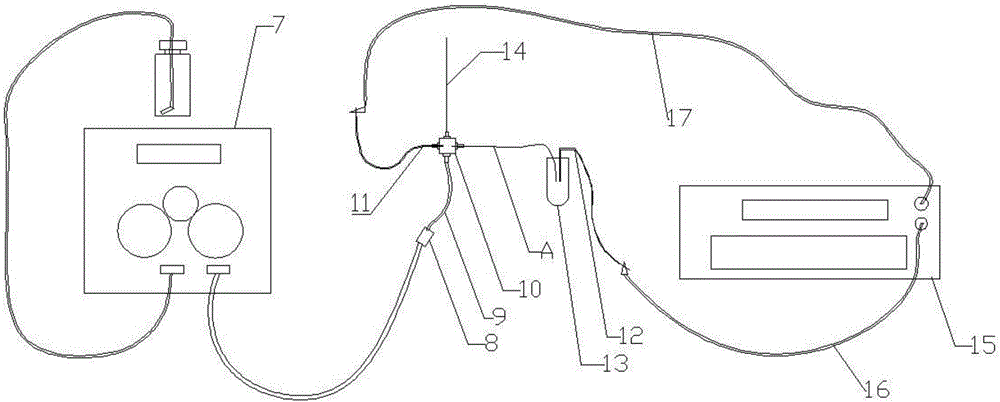

[0045] The embodiment of the present invention provides a method and system for preparing a nano-tip pipette that integrates micro-nano capillary drawing, wet etching and current detection. Now, a micro-nano capillary with an outer diameter of 360 μm and an inner diameter of 0.9 μm is used to prepare a nanometer tip pipette. The tip pipette is taken as an example to describe the present invention in detail, and the specific implementation steps are as follows:

[0046] S1. Configure 0.1mol / L KCl solution and filter twice; configure 0.2mol / L HCl solution and filter before use; configure 0.1mol / L NaOH solution; configure HF concentration of 2%-5% etching solution (mixture of dilute KCl solution+original HF solution); prepare two platinum electrodes (11, 12);

[0047] S2. Change the mobile phase of the high-pressure infusion pump (7) into a 0.1mol / L KCl solution;

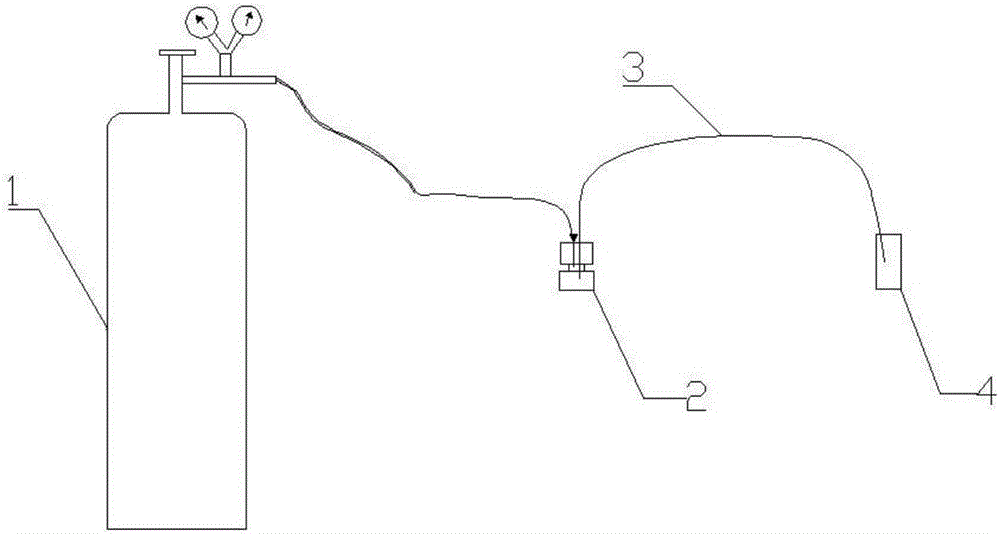

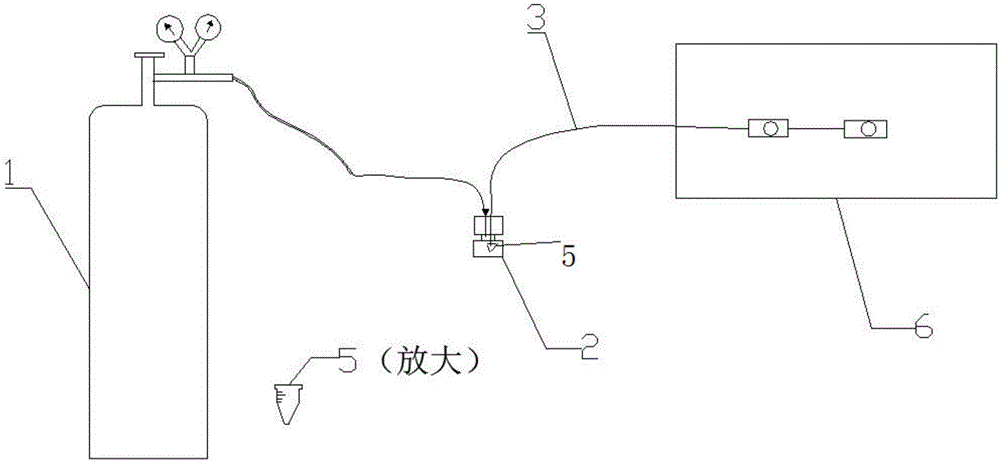

[0048] S3. Using the capillary permeability verification device ( figure 1 ) to verify the permeability of the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com