Preparation method of black zirconia ceramic

The technology of black zirconia and ceramics is applied in the field of preparation of black zirconia ceramics, which can solve the problems of high production cost and complicated preparation process, and achieve the effects of low equipment investment and production cost, simple process method and low dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

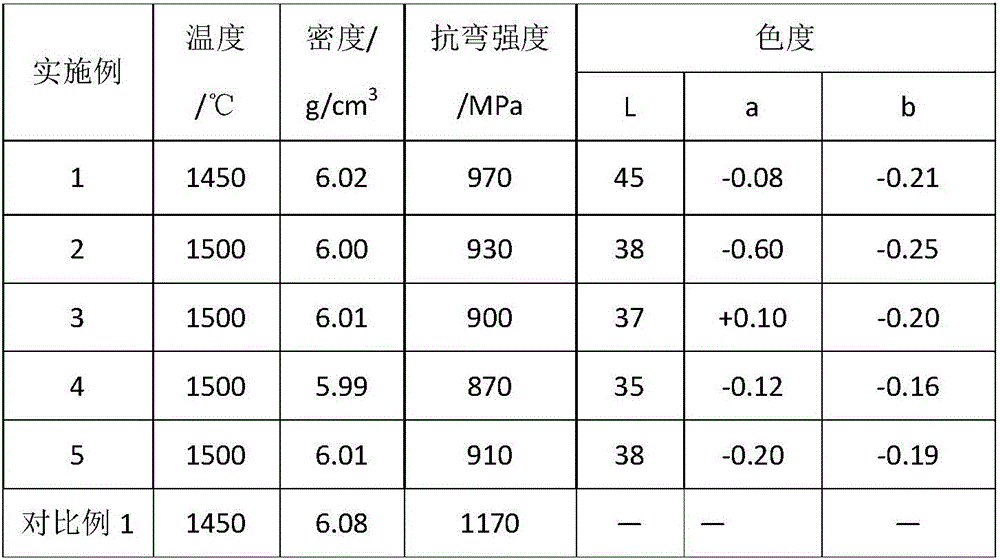

[0020] 1.1g of lanthanum oxide, 0.25g of calcium oxide, 0.25g of chromium oxide and 0.4g of alumina were wet-ground to a particle size of less than 1μm and mixed uniformly. Then the slurry was dried and calcined in a muffle furnace at 1200°C. After hours, grind and crush to obtain black toner (La0.6Ca0.4Al0.7Cr0.3O3); mix the above-mentioned black toner (the black toner accounts for 2.5% of the mass fraction of zirconia powder) with 78g of zirconia powder by ball milling, Press molding and sintering at 1450°C for 2 hours to obtain black zirconia ceramics.

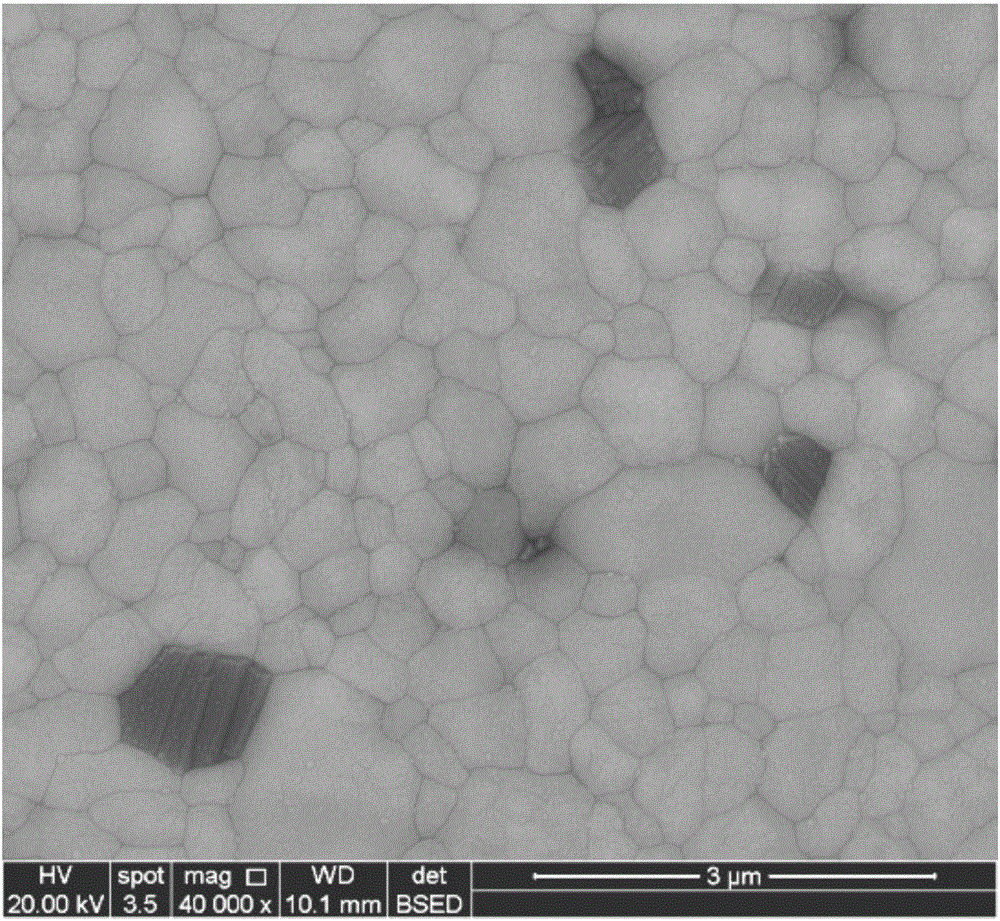

[0021] See figure 1 It can be seen from the figure that the prepared black zirconia ceramic has no residual pores, and the added black toner particles are evenly distributed in the zirconia matrix. The prepared black zirconia ceramic has good mechanical properties and black chromaticity, the density is 6.02g / cm3, the bending strength is 970MPa, the chromaticity value L=45, a=-0.08, b=-0.21.

Embodiment 2

[0023] The black toner synthesized in Example 1 (the black toner accounts for 2.5% of the mass fraction of the zirconia powder) is uniformly mixed with 78g zirconia powder by ball milling, pressed into a shape, and calcined at 1450°C for 1 hour to obtain a black zirconia ceramic . The prepared black zirconia ceramic has a density of 6.00g / cm3, a bending strength of 930MPa, a chromaticity value of L=38, a=-0.60, and b=-0.25.

Embodiment 3

[0025] 1.06g of lanthanum oxide, 0.24g of calcium oxide, 0.41g of chromium oxide and 0.28g of alumina were wet-milled and mixed uniformly, then the slurry was dried, calcined in a muffle furnace at 1050°C for 1 hour, and ground and crushed to obtain a black (La0.6Ca0.4Al0.5Cr0.503); mix 64.3g of zirconia powder with the synthesized black toner (black toner accounts for 3% of the zirconia powder mass fraction) by ball milling, press and shape, and calcinate at 1500℃ In 2 hours, black zirconia ceramics were obtained. The prepared black zirconia ceramic has a density of 6.02g / cm3, a bending strength of 900MPa, a chromaticity value of L=36, a=+0.10, b=-0.20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com