A kind of modification method of nanocellulose crystal viscoelasticity

A nanocellulose and viscoelastic technology, applied in the field of modification of nanocellulose crystals, can solve problems such as the reduction of nanocellulose crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Preparation of nanocellulose:

[0039] Straw cellulose is passed through a 20-mesh sieve, and dispersed in 65% (w / w) H 2 SO 4 In the solution, ultrasonic treatment (40 KHz, 30 s) was performed for 90 minutes under the condition of a constant temperature water bath at 45° C., during which time stirring was performed at 100 r / min. The reaction was terminated with 10 times the volume of acid solution in deionized water. A milky white suspension was obtained, centrifuged at 12000 r / min, 15 min each time, until the precipitate was washed with water to pH=7, and the supernatant was removed to obtain a stable cellulose colloid. Then disperse the precipitate with deionized water and redisperse it by ultrasonic wave (40KHz, 30s). Pour the dispersion liquid into a plate to freeze in a -20°C refrigerator for 24h, and freeze-dry at -70°C for 48h to obtain powdered nanocellulose crystals.

[0040] Described measuring method is as follows:

[0041] Determination of shear viscosit...

Embodiment 1

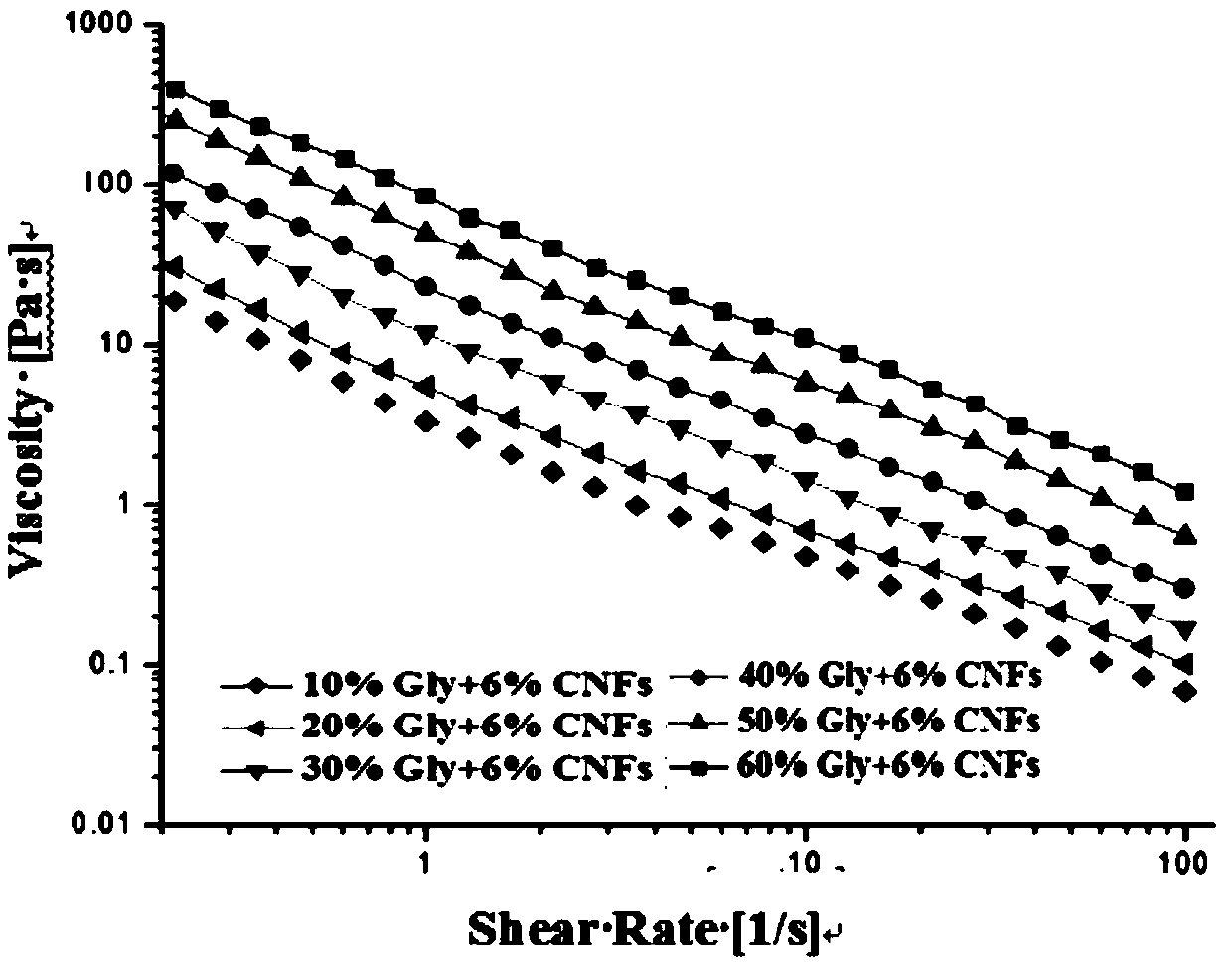

[0046] Preparation of nanocellulose crystal suspensions with different concentrations of glycerol:

[0047] The NCC of certain quality is dispersed in the 10Ml glycerol solution, is made into the suspension of 6% (w / v) NCC, and the glycerol solution mass distribution is as follows:

[0048] 10% (w / w) glycerol NCC suspension: 0.6g NCC is dispersed into 1g glycerol and 9ml deionized water mixture;

[0049] 20% (w / w) glycerol NCC suspension: 0.6g NCC is dispersed into 2g glycerol and 8ml deionized water mixture;

[0050] 30% (w / w) glycerol NCC suspension: 0.6g NCC is dispersed into 3g glycerol and 7ml deionized water mixture;

[0051] 40% (w / w) glycerol NCC suspension: 0.6g NCC is dispersed into 4g glycerol and 6ml deionized water mixture;

[0052] 50% (w / w) glycerol NCC suspension: 0.6g NCC is dispersed into 5g glycerol and 5ml deionized water mixture;

[0053] 60% (w / w) glycerol NCC suspension: 0.6g NCC is dispersed into 6g glycerol and 4ml deionized water mixture;

[0054]...

Embodiment 2

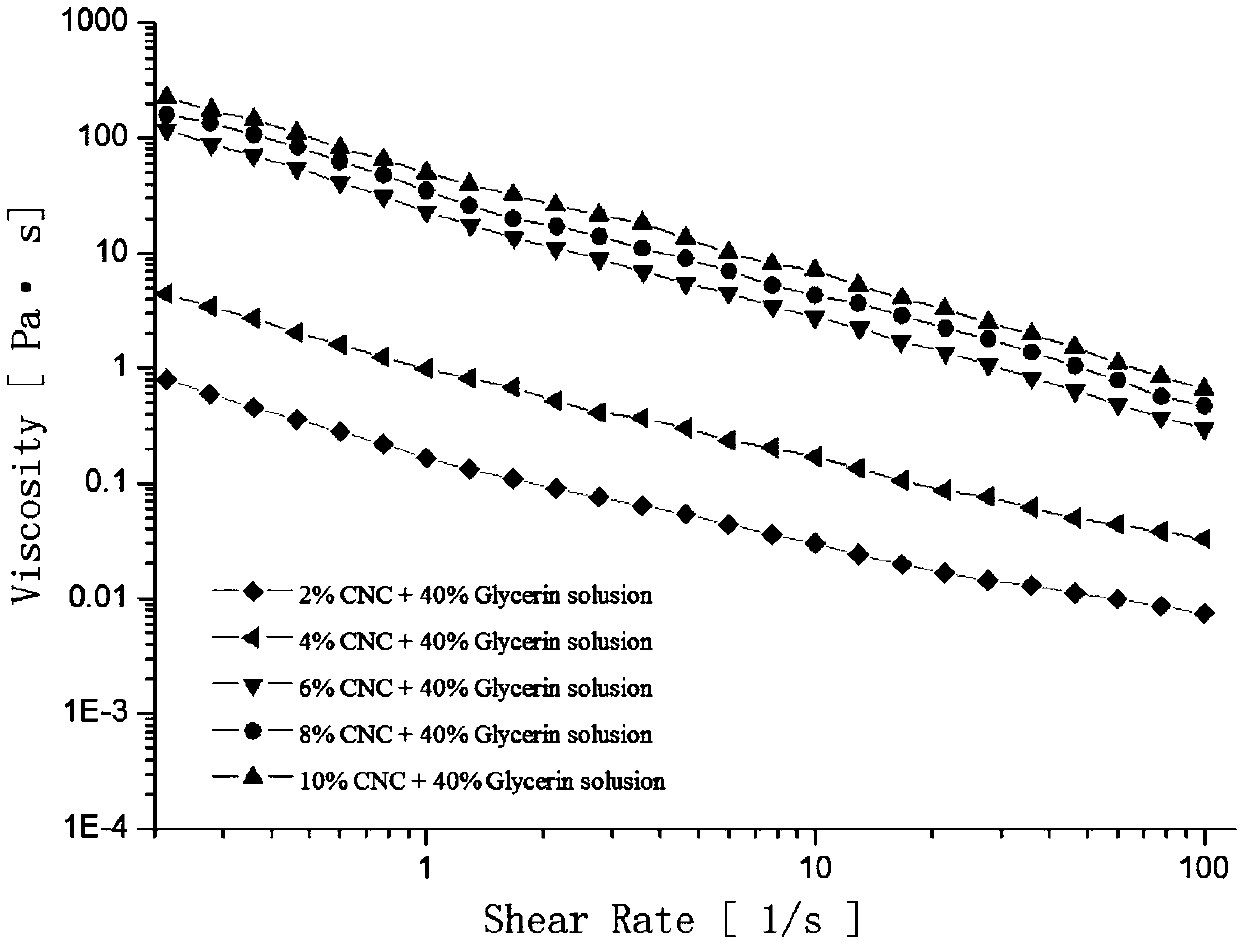

[0058] Preparation of glycerol suspensions with different concentrations of nanocellulose crystals:

[0059] A certain quality of NCC is dispersed in 10mL glycerol solution, and is made into the NCC suspension of 40% (w / w) glycerol, and the NCC mass distribution is as follows:

[0060] 2% (w / v) NCC glycerol suspension: 0.2g NCC is dispersed into 4g glycerol and 6ml deionized water mixture;

[0061] 4% (w / v) NCC glycerol suspension: 0.4g NCC is dispersed into 4g glycerol and 6ml deionized water mixture;

[0062] 6% (w / v) NCC glycerol suspension: 0.6g NCC is dispersed into 4g glycerol and 6ml deionized water mixture;

[0063] 8% (w / v) NCC glycerol suspension: 0.8g NCC is dispersed into 4g glycerol and 6ml deionized water mixture;

[0064] 10% (w / v) NCC glycerin suspension: 1.0g NCC is dispersed into 4g glycerol and 6ml deionized water mixture;

[0065] Then, ultrasonically disperse at room temperature (10min, 40KHZ).

[0066] From figure 2 It can be seen from the figure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com