A special material used for cables with high shock resistance and prepared from recovered waste polyethylene and a preparing method thereof

A technology of waste polyethylene and special materials, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problem of high price, and achieve the effect of large friction coefficient, high tensile strength and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

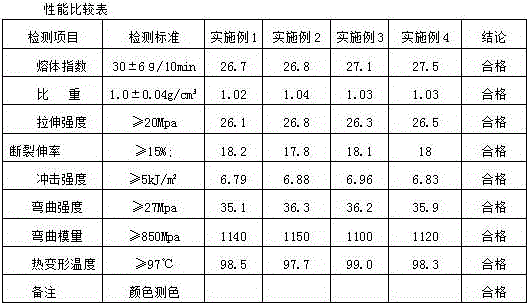

Examples

Embodiment 1

[0023] Recipe and preparation method:

[0024] 1. Formula:

[0025] Chlorinated polyethylene 8 parts

[0026] Recycle 68 parts of waste polyethylene

[0027] Colored carbon black 5 parts

[0028] ACR impact modifier 7 parts

[0029] Auxiliary 2 parts

[0030] Anhydrous calcium sulfate 10 parts

[0031] 2. Preparation method:

[0032] (1) After physically pulverizing all the above-mentioned bulk raw materials, the raw materials are measured according to the formula and put into a high-speed mixer for uniform mixing to make a mixture of recycled waste polyethylene; the uniformly mixed materials are added to the twin-screw extruder In the middle, wire drawing and granulation are carried out.

[0033] (2) The processing temperature of each section of the extruder is as follows:

[0034] Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

[0035] 120°C 130°C 140°C 145°C 150°C 150°C

Embodiment 2

[0037] 1. Formula:

[0038] Chlorinated polyethylene 6 parts

[0039] Recycle 65 parts of waste polyethylene

[0040] Colored carbon black 7 parts

[0041] ACR impact modifier 6 parts

[0042] Auxiliary 3 parts

[0043] Anhydrous calcium sulfate 13 parts

[0044] 2. Preparation method:

[0045] (1) After physically pulverizing all the above-mentioned bulk raw materials, the raw materials are measured according to the formula and put into a high-speed mixer for uniform mixing to make a mixture of recycled waste polyethylene; the uniformly mixed materials are added to the twin-screw extruder In the middle, wire drawing and granulation are carried out.

[0046] (2) The processing temperature of each section of the extruder is as follows:

[0047] Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

[0048] 120°C 130°C 140°C 145°C 150°C 150°C

Embodiment 3

[0050] 1. Formula:

[0051] Chlorinated polyethylene 5 parts

[0052] Recycle 70 parts of waste polyethylene

[0053] Colored carbon black 6 parts

[0054] ACR impact modifier 7 parts

[0055] Auxiliary 2.5 parts

[0056] Anhydrous calcium sulfate 9.5 parts

[0057] 2. Preparation method:

[0058] (1) After physically pulverizing all the above-mentioned bulk raw materials, the raw materials are measured according to the formula and put into a high-speed mixer for uniform mixing to make a mixture of recycled waste polyethylene; the uniformly mixed materials are added to the twin-screw extruder In the middle, wire drawing and granulation are carried out.

[0059] (2) The processing temperature of each section of the extruder is as follows:

[0060] Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

[0061] 120°C 130°C 140°C 145°C 150°C 150°C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com