Environment friendly chalk and a manufacturing method thereof

An environmentally friendly, chalk technology, used in pencil leads, household appliances, applications, etc., can solve the problems of air pollution, seldom recycling of chalk dust, and laborious writing, and achieve the effect of low dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

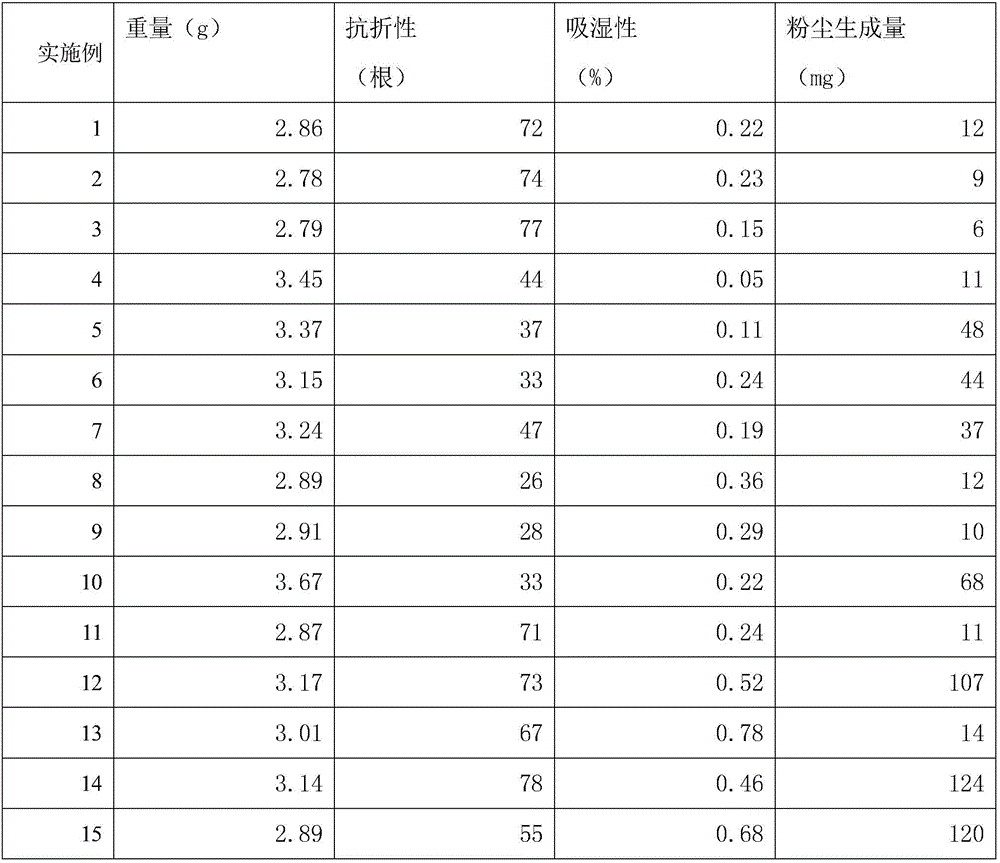

Examples

Embodiment 1

[0050] First, obtain calcium sulfate powder, calcium carbonate powder, talc powder, sepiolite powder, montmorillonite powder and titanium dioxide powder.

[0051] Then, the above-mentioned powders were sieved twice respectively, that is, the purchased calcium sulfate powder, calcium carbonate powder, talc powder, sepiolite powder, and smog were sieved using a 100-mesh sieve (with a mesh aperture of 150 microns). The de-earth powder and titanium dioxide powder have a particle size greater than 150 microns, and then use a 1000-mesh sieve (mesh aperture of 13 microns) to sieve out components with a particle size less than 10 microns for later use.

[0052] Using water, 50 parts by weight of calcium sulfate powder, 20 parts by weight of calcium carbonate powder, and 10 parts by weight of talc powder obtained by secondary sieving were prepared into a first slurry with a solid content of 60% by weight. Add 2 parts by weight of sepiolite powder obtained by secondary sieving to the first s...

Embodiment 2 to 10

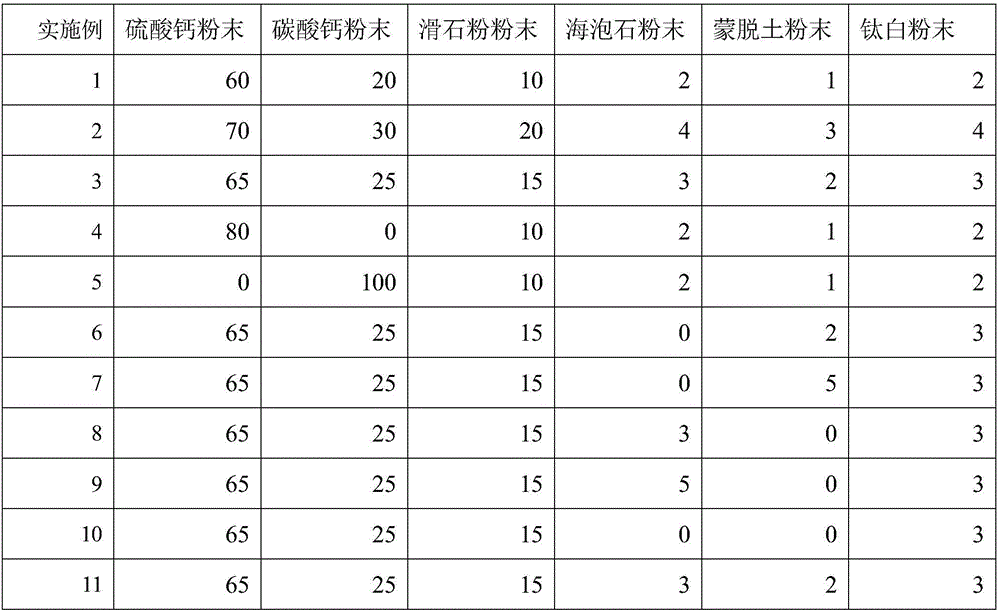

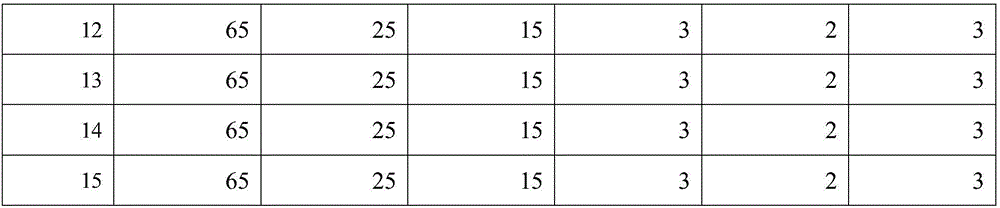

[0063] Except for the content shown in Table 1 below, the same method as in Example 3 was used.

Embodiment 11

[0065] It was carried out basically in the same manner as in Example 3, except that the third slurry was heated at 60°C for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com