Preparation method of canned red bayberry fruits

A technology for canning and red bayberry, which is applied in the field of preparation of canned red bayberry, can solve the problems of short shelf life of canned red bayberry products, affecting the flavor and color of cans, and difficult storage and transportation of fruits, and achieves obvious flavor of red bayberry, obvious aroma of roselle, and repellent good insect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

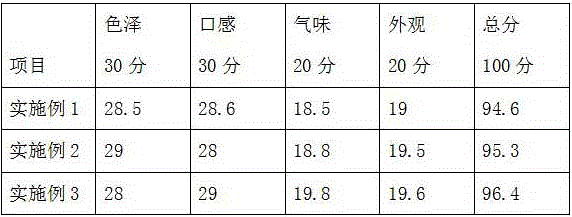

Examples

Embodiment 1

[0041] (1) Selection and processing of raw materials

[0042] ①Choose red bayberry with a fruit diameter of 3-4cm, fresh, good flavor and purple red as raw material;

[0043] ②Remove unqualified fruit, remove the stalk, rinse with flowing water, then immerse the bayberry in white wine with a volume concentration of 20%, soak for 15 minutes at 32°C, take it out, wash with water, and dry;

[0044] 3. the red bayberry that step 2. has been processed is put into an ultrasonic cleaner for cleaning, and the solution in the ultrasonic cleaner is a saline solution with a mass concentration of 3%. After cleaning, it is washed with clear water and dried; the ultrasonic cleaner cleans The power of the ultrasonic cleaner is 50W, the temperature of the ultrasonic dispersion is 35°C, and the cleaning time of the ultrasonic cleaner is 10min.

[0045] ④ Add mixed fruit enzymes to the bayberry treated in step ③ at a mass ratio of 1:2, soak at 42°C for 14 hours, continue to heat up to 64°C and...

Embodiment 2

[0068] (1) Selection and processing of raw materials

[0069] ① Select the red bayberry with a fruit diameter of 3-4cm, fresh, good flavor and purple red as raw material;

[0070] ② Remove unqualified fruit, remove the stalk, rinse with flowing water, then immerse the bayberry in white wine with a volume concentration of 25%, soak for 15 minutes at 28°C, take it out, wash with water, and dry;

[0071] 3. the red bayberry that step 2. has been processed is put into an ultrasonic cleaner for cleaning, and the solution in the ultrasonic cleaner is a saline solution with a mass concentration of 4%. After cleaning, wash with clear water and dry; the ultrasonic cleaner cleans The power of the ultrasonic cleaner is 100W, the temperature of the ultrasonic dispersion is 32°C, and the cleaning time of the ultrasonic cleaner is 5min.

[0072] ④ Add mixed fruit enzymes to the bayberry treated in step ③ at a mass ratio of 1:3, soak at 46°C for 12 hours, continue to heat up to 72°C and kee...

Embodiment 3

[0095] (1) Selection and processing of raw materials

[0096] ① Select the red bayberry with a fruit diameter of 3-4cm, fresh, good flavor and purple red as raw material;

[0097] ② Remove unqualified fruit, remove the stalk, rinse with flowing water, then immerse the bayberry in white wine with a volume concentration of 22%, soak for 16 minutes at 30°C, take it out, wash with water, and dry;

[0098] 3. the red bayberry that step 2. has been processed is put into an ultrasonic cleaner for cleaning, and the solution in the ultrasonic cleaner is a saline solution with a mass concentration of 3.5%. After cleaning, wash with clear water and dry; the ultrasonic cleaner cleans The power of the ultrasonic cleaner is 80W, the temperature of the ultrasonic dispersion is 33°C, and the cleaning time of the ultrasonic cleaner is 8min.

[0099] ④ Add mixed fruit enzymes to the bayberry processed in step ③ at a mass ratio of 1:2.5, soak at 44°C for 13 hours, continue to heat up to 68°C an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com