A laser metal additive manufacturing method with automatic cooperative controllable light spot and powder spot

A metal additive and manufacturing method technology, which is applied in the field of laser metal additive manufacturing devices, can solve problems such as the inability to guarantee the forming quality of variable melting width forming, and achieve the effect of taking into account efficiency and precision, improving cladding accuracy, and improving forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

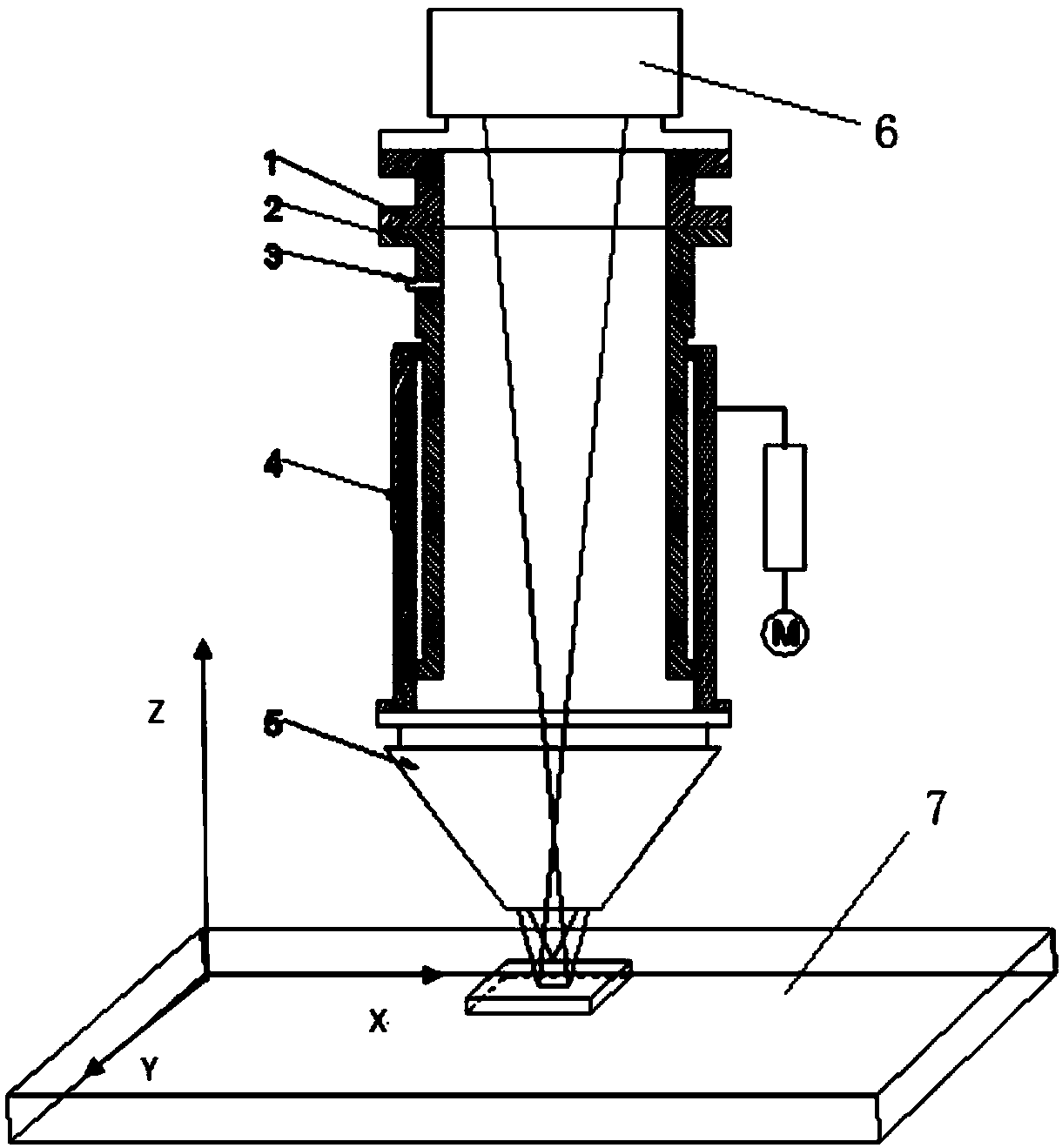

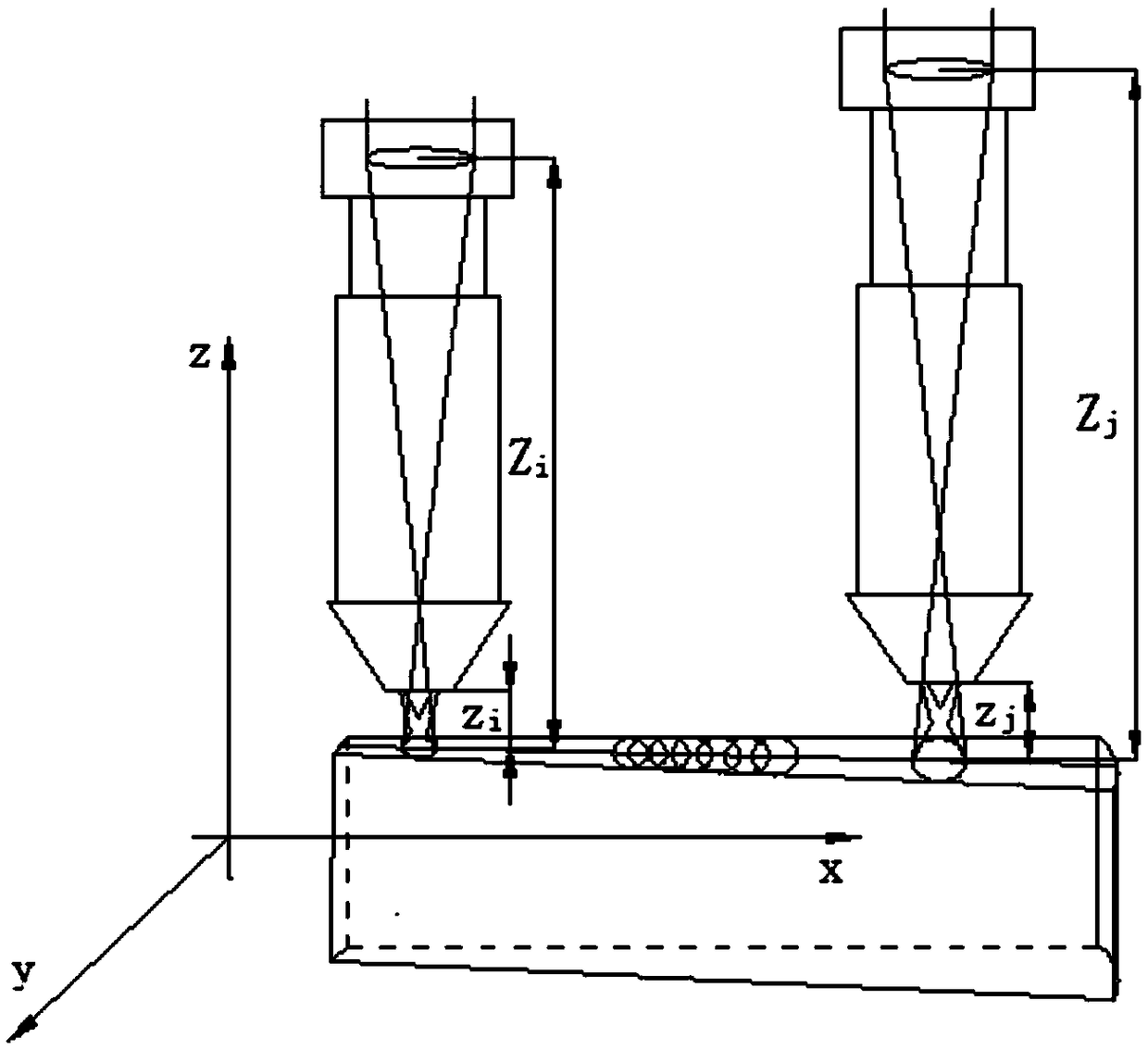

[0035] When adopting the method described in the present invention to form the member with variable wall thickness in one pass, such as figure 2 As shown, it includes the following steps.

[0036] Step 1. Obtain the correspondence between the spot size of the workpiece processing surface and the distance Z from the focusing mirror to the workpiece processing surface, and the relationship between the powder spot size and the distance z from the powder feeding nozzle to the workpiece processing surface through experimental measurement and optical geometry calculation. Correspondence;

[0037] Step 2, through the process experiment and the measurement of the geometric dimensions of the cladding layer, establish a process database including the correspondence between the three data of cladding layer size, spot size and powder spot size, and establish the cladding layer size based on the data of the process database Controllable spot and powder spot synergistic control strategy; ...

example 2

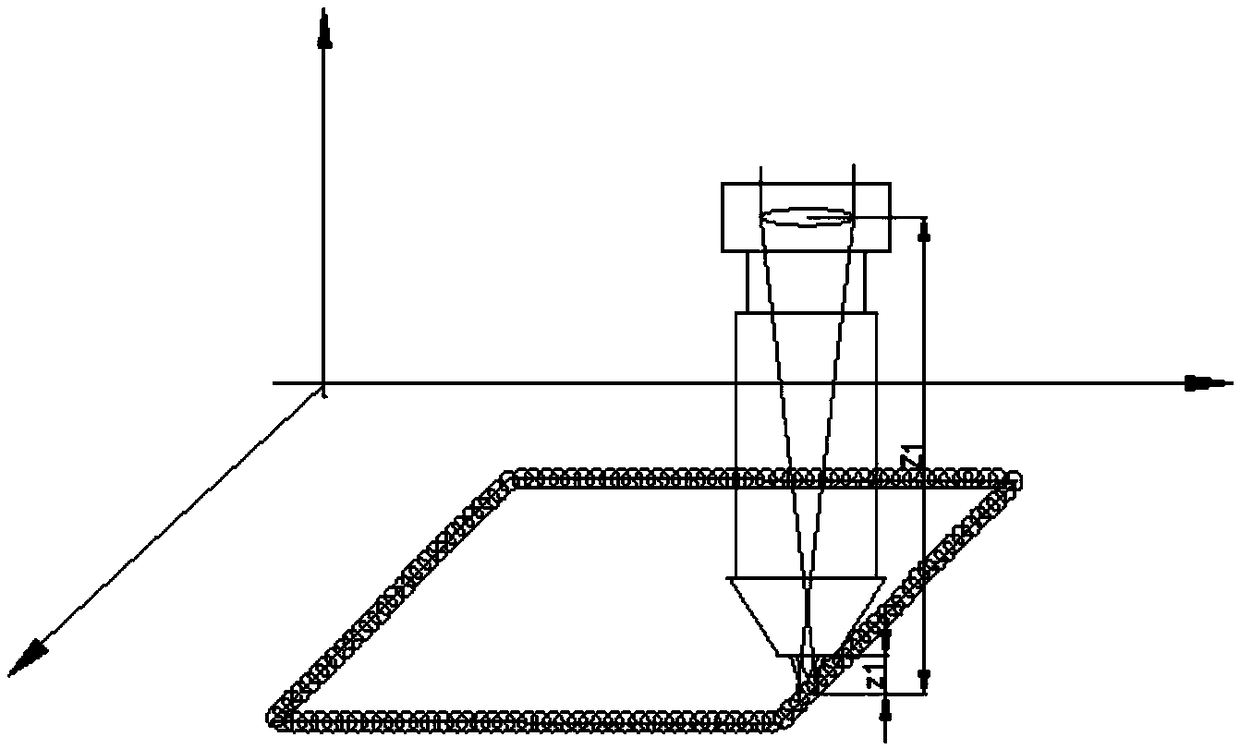

[0044] Using the method of the present invention to improve the forming efficiency and precision of laser additive manufacturing when forming thick and large components, such as Figure 4 As shown, it specifically includes the following steps:

[0045] Step 1. Obtain the correspondence between the spot size of the workpiece processing surface and the distance Z from the focusing mirror to the workpiece processing surface, and the relationship between the powder spot size and the distance z from the powder feeding nozzle to the workpiece processing surface through experimental measurement and optical geometry calculation. Correspondence;

[0046] Step 2, through the process experiment and the measurement of the geometric dimensions of the cladding layer, establish a process database including the correspondence between the three data of cladding layer size, spot size and powder spot size, and establish the cladding layer size based on the data of the process database Controlla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com