Automatic centering electric rotating chuck

An electric rotation and automatic centering technology, applied in auxiliary devices, applications, laser welding equipment, etc., can solve problems such as unsuitable clamping of pipe fittings, large force on coil springs, and reduced machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

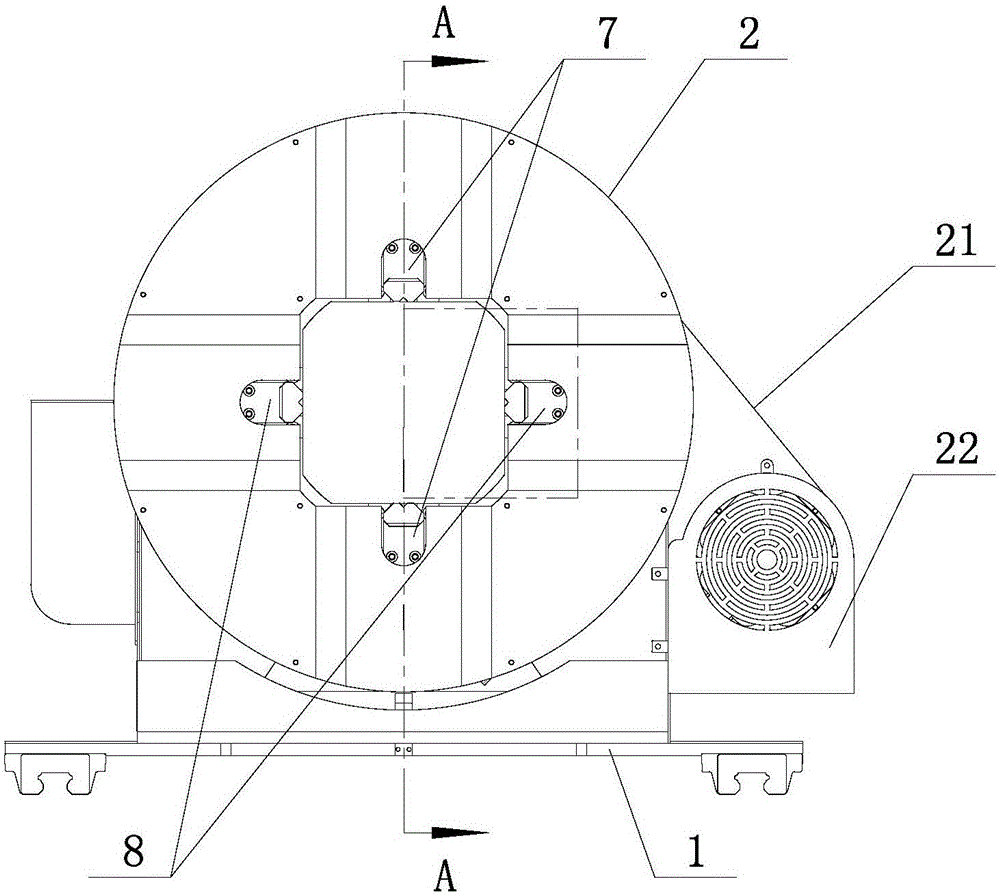

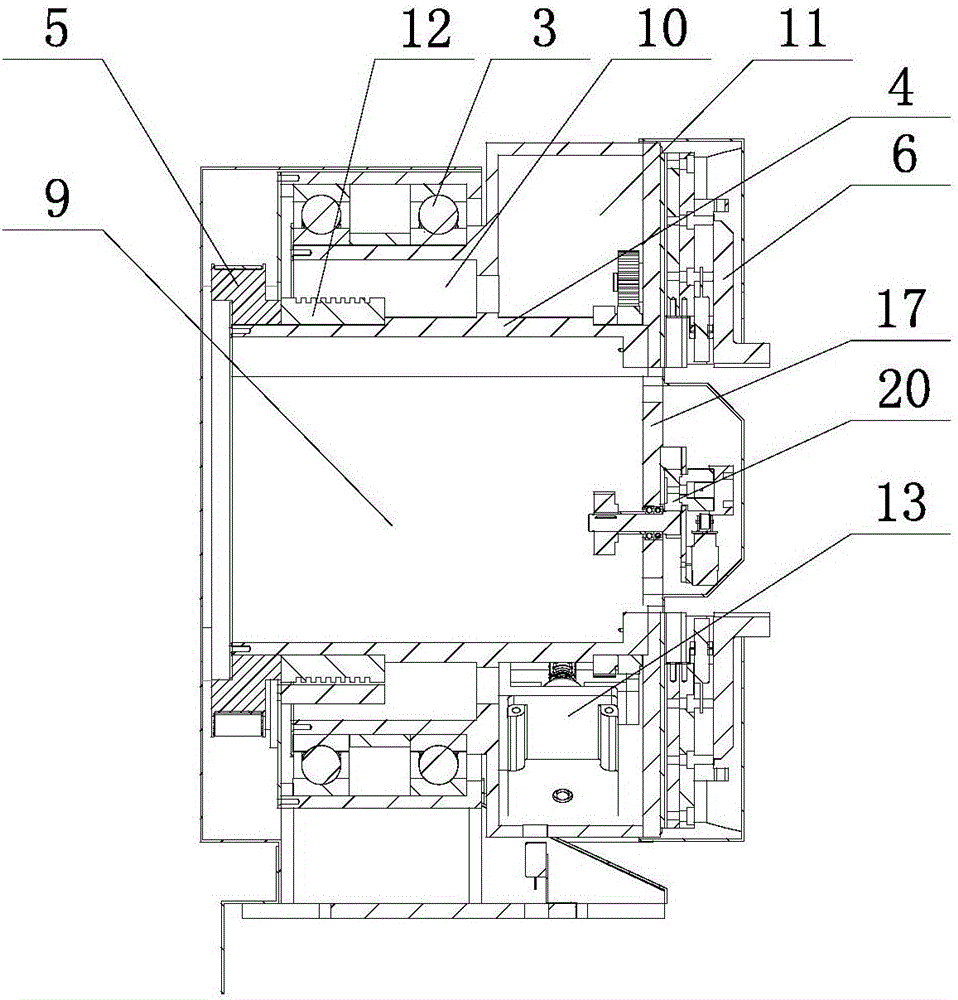

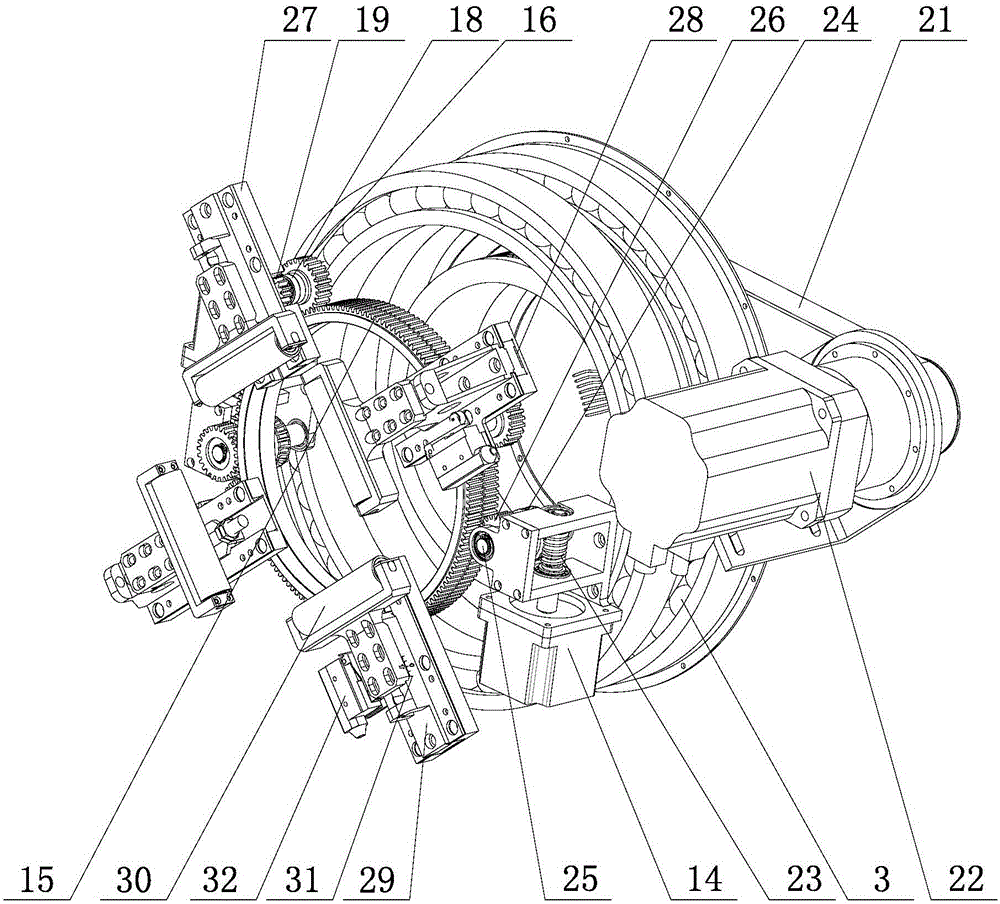

[0031] like Figure 1-3 As shown, an automatic centering electric rotating chuck includes a base 1, a bearing seat 2 is arranged on the base 1, a bearing 3 is arranged in the bearing seat 2, the inner ring of the bearing 3 is connected with the rolling core 4, and one end of the rolling core 4 is connected There is a rolling core drive device, and the other end of the rolling core end wall is provided with two sets of clamping jaw mechanisms 6 arranged in a cross shape. The two clamping jaw mechanisms 6 are the second group of clamping jaw mechanisms 8 , at least one clamping jaw mechanism 6 in each group of clamping jaw mechanisms is provided with a sensor 32 , the center of the rolling core 4 is provided with a through hole 9 , and the inner wall of the rolling core 4 is provided with a sensor 32 . There are a first cavity 10 and a second cavity 11, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com