Processing method of integral guide apparatus

A processing method and technology of guides, which are applied in the direction of machines/engines, stators, engine components, etc., can solve problems such as cracking of brazing seams, and achieve the effects of precise dimensions, reduced manufacturing costs, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

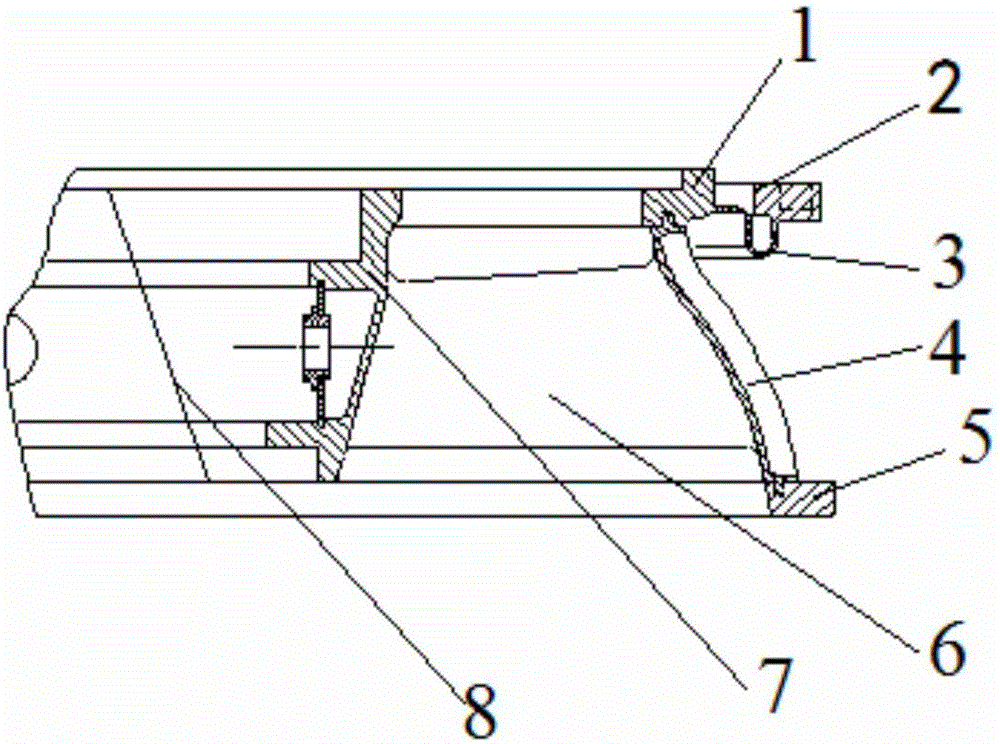

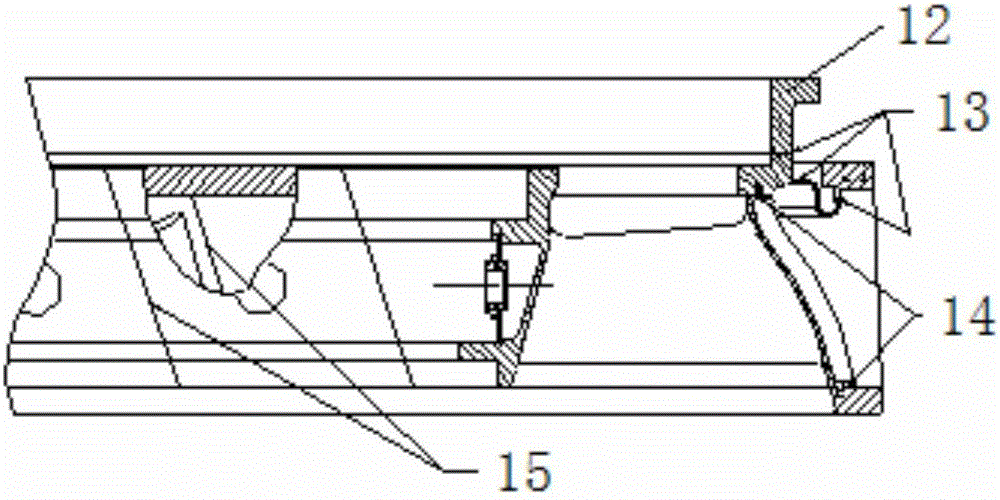

[0028] (1) Part status

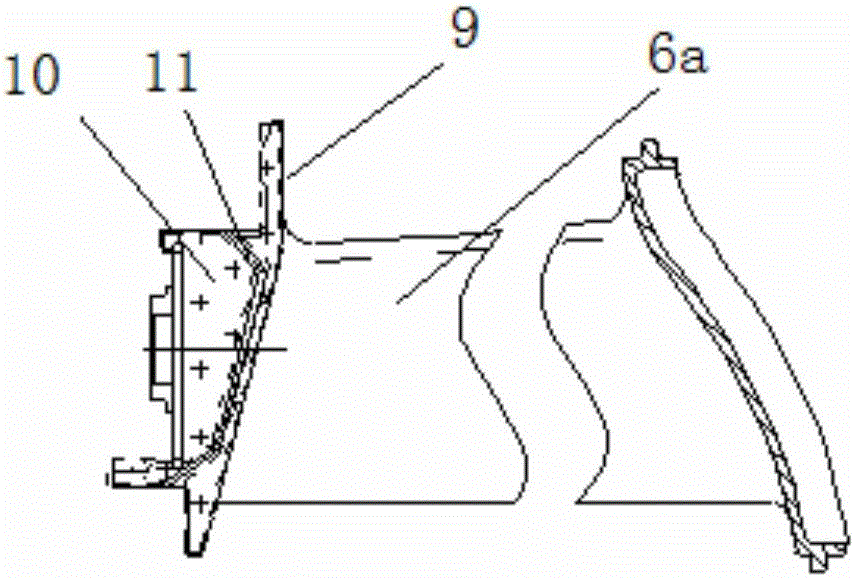

[0029] The integral guide is composed of front mounting edge 1, rear mounting edge 5, blade assembly (18 pieces) 6, bellows 3 and bellows front ring 2. The structure of the integral guide is as follows: figure 1 shown. The material of the front mounting edge 1, the rear mounting edge 5 and the bellows front ring 2 is GH3044 superalloy, the material of the bellows 3 is GH3030 superalloy, and the material of the blade assembly (18 pieces) 6 is K403 superalloy.

[0030] (2) Processing equipment

[0031] The main processing equipment includes: vacuum electron beam welding machine, energy storage spot welding machine, vacuum brazing furnace and large lathe.

[0032] (3) Implementation process

[0033] Step 1: Processing preparation

[0034] Pre-assemble the front mounting edge 1, blade (18 pieces) 6, and rear mounting edge 5 on the assembly fixture, and control the amount of misalignment between the blade edge plate assembly edges by selecting blades to...

Embodiment 2

[0052] (1) Part status

[0053] The integral guide is composed of front mounting edge 1, rear mounting edge 5, blade assembly 618 pieces), bellows 3 bellows front ring 2, and the structure of the integral guide is as follows figure 1 shown. The material of the front mounting 1, the rear mounting edge 5 and the bellows front ring 2 is GH4648 superalloy, the material of the bellows 3 is GH3030 superalloy, and the material of the blade assembly (18 pieces) is K403 superalloy.

[0054] (2) Processing equipment

[0055] The main processing equipment includes: vacuum electron beam welding machine, energy storage spot welding machine, vacuum brazing furnace, large lathe.

[0056] (3) Implementation process

[0057] Step 1: Processing preparation

[0058] Pre-assemble the front mounting edge 1, blade 6a (18 pieces), and rear mounting edge 5 on the assembly fixture, and control the amount of misalignment between the blade edge plate assembly edges by selecting blades to be no more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com