High-added-value treating method for waste culture liquid of Dunaliella salina

A treatment method and high value-added technology, applied in microorganism-based methods, filtration treatment, water/sewage treatment, etc., can solve problems such as the reduction of the activity of salina polysaccharides, and achieve the effect of reducing emissions, reducing costs, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

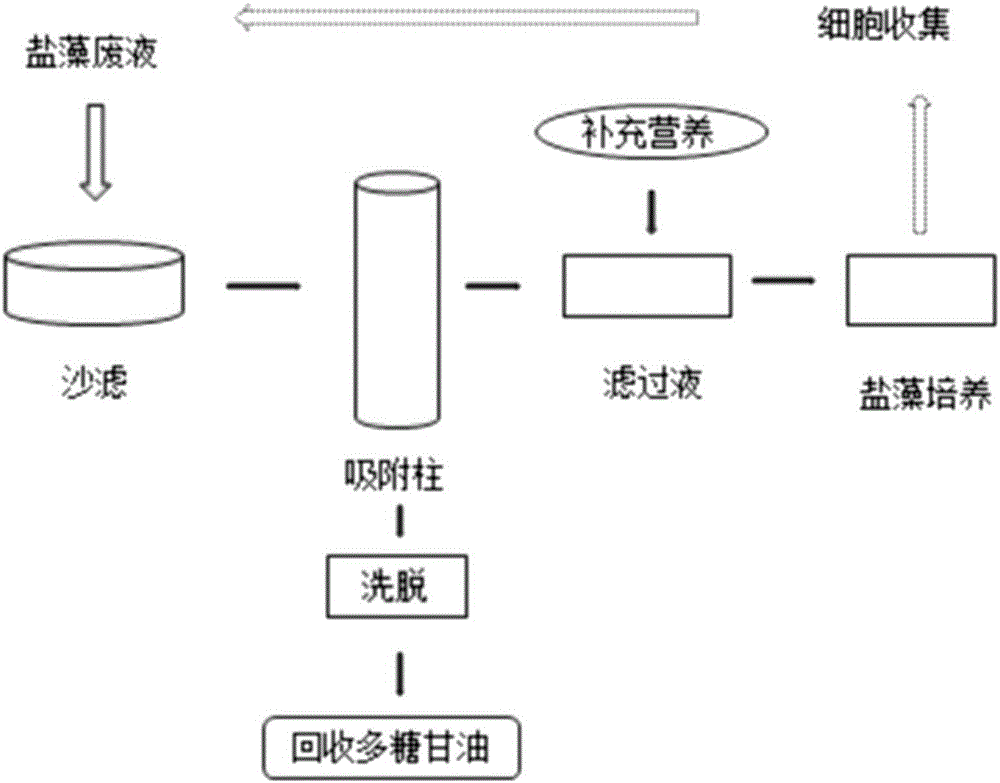

Method used

Image

Examples

Embodiment 1

[0053] Effect of Different Sand Filtration Conditions on Filtration Results

[0054] Sand filter setting parameters First, the selection range of sand particle size is 0.5 ~ 1.5, 1.5 ~ 3, 3 ~ 4.5mm, the sand filter thickness is 0.7m, and the sand filter filtrate of 1.5 ~ 3.5mm is determined to be free of solid suspended particles; the flow rate setting range is 200~500L / h, 500~1000L / h 1000~1500L / h, 1500~2000L / h, it proves that the filtrate of 1000~1500L / h is clear, there is no solid precipitation after standing and the efficiency is high;

Embodiment 2

[0056] Effect of different filter column conditions on filtration results

[0057] (1) Set the filler ratio to 8 / 10, set the flow rate to 500L / h, 600L / h, 700L / h, 800L / h, 900L / h, 1000L / h, and treat for 5 hours. The experimental results show that the flow rate is 700L / h At ~900L / h, the adsorption rates of salina exopolysaccharide and glycerol are about 89% and 58%, respectively, which is beneficial to the adsorption efficiency;

[0058] (2) Set different processing time to determine the processing capacity: 5~7h, 7~9h, 9~11h, 11~13h, when the processing time is 9h~11h, the adsorption rates of salina polysaccharide and glycerin are about 86% and 55% respectively ;

Embodiment 3

[0060] Determination of different elution conditions

[0061] ⑴ After being treated with macroporous resin X-5 adsorption column for 10 hours, elution is carried out, and the elution conditions are set at a sodium chloride concentration of 0.5% to 1%, 1% to 2%, 2% to 3%, 3% to 4 %, at a temperature of 25°C, elute with an eluent with a pH value of 7 at a flow rate of 1500 L / h for 3 hours. The results showed that when the salt concentration was 2% to 3%, the elution rate was over 70%; the yields of salina exopolysaccharide and glycerin were 9.4% and 7.6%, respectively.

[0062] (2) Set the pH range of the eluent as pH=5~6, 6~7, 7~8, 8~9, the elution salt concentration is 2.5%, the temperature is 25°C, and the flow rate is 1500L / h for 3 hours. When the pH value was 8, the elution rate was above 76%; the recoveries of salina exopolysaccharide and glycerol were 9.6% and 7.7%, respectively.

[0063] (3) The elution temperature setting range is 20-25°C, 25-30°C, 30-35°C, 35-40°C, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com