A ceramic brick pattern penetrating method

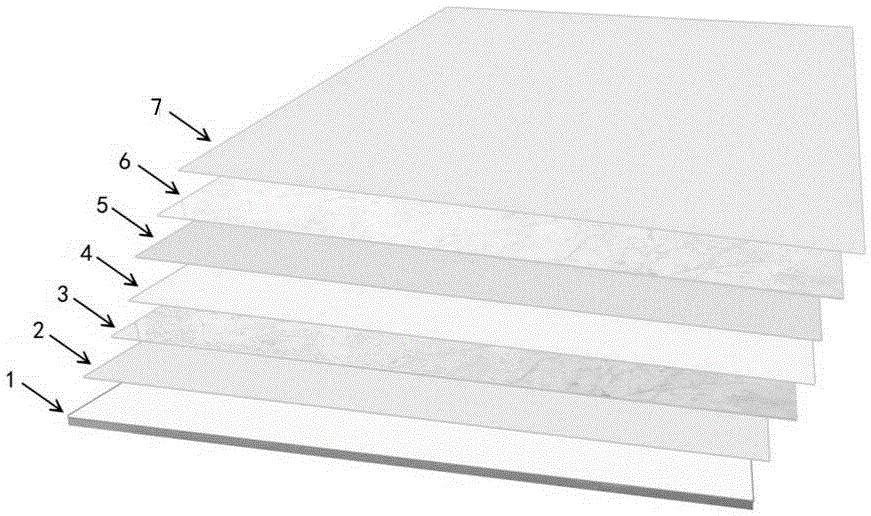

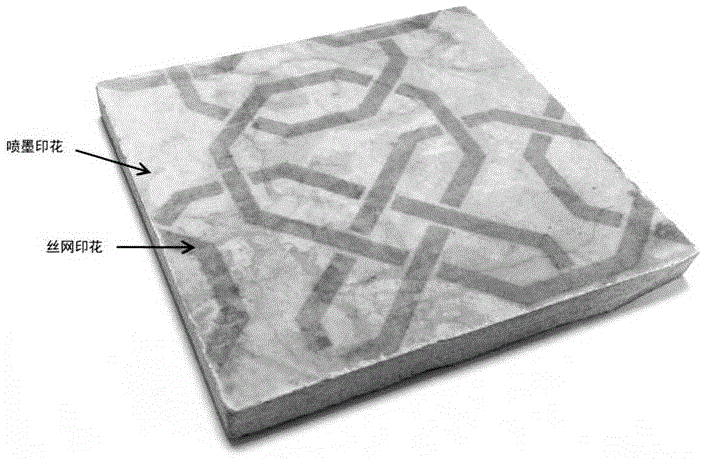

A kind of ceramic tile and fancy technology, which is applied in the field of architectural ceramic decoration, can solve the problems of expensive, undiscovered penetration products, and inability to adopt, etc., and achieve the effect of natural bionic effect, rich patterns, and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

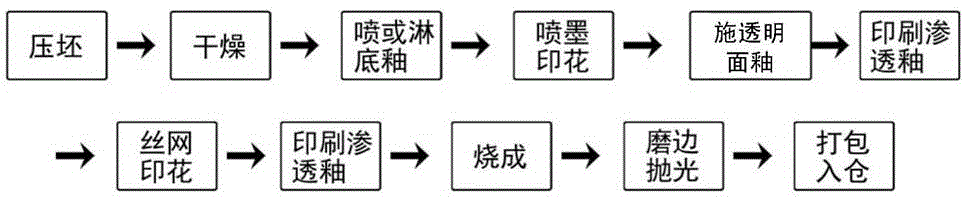

[0042] 1. The compact is formed, and after drying, it is dried at 100-250°C for 45 minutes;

[0043] 2. Spray or drench the bottom glaze on the dried brick. Calculated by mass percentage, the bottom glaze composition includes: potassium feldspar 25-32%, albite 8-12%, quartz 15-25%, limestone 5% ~10%, burnt talc 10~15%, burnt clay 8~15%, kaolin 2~5%;

[0044] 3. Inkjet printing. Inkjet printing fancy patterns on the glazed brick surface. The ink uses the inkjet bleeding ink provided by the ink company on the market (manufacturer: Shanghai Meigao Color Co., Ltd.) agent (manufacturer: Shanghai Meigao Pigment Co., Ltd., model: MET FLUID BS). The color of the bleeding ink provided by it is mainly brown (model: INKMET L253MB1), yellow (model: INKMET L237YB3), blue (model: INKMET L023CB1), black (model: INKMETL073HB1). The spray volume relationship between ink and penetration aid is about 1:3, and the gray scale of ink plus penetration aid is 100%;

[0045] 4. Spray or drench the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com