Tnt/tncb eutectic explosive and preparation method thereof

A technology of TNT-TNCB and eutectic explosives, applied in explosives processing equipment, explosives, explosive compound components, etc., can solve the problems of no open literature reports, restricted development, large pore shrinkage rate, etc., and achieve excellent safety and product quality. High-quality, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

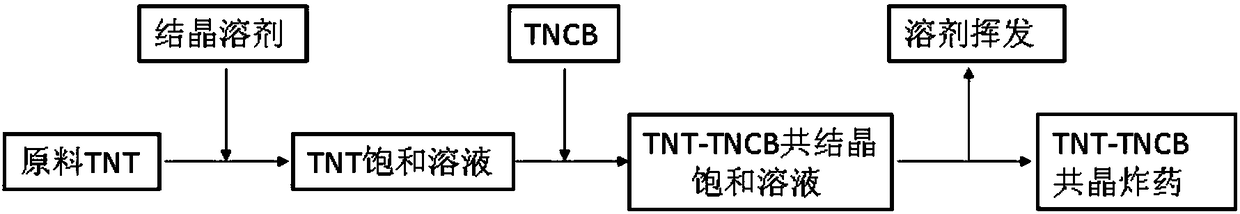

[0031] At room temperature, 30ml of acetone was added into the three-necked flask, and then a sufficient amount of TNT was added under stirring, dissolved and filtered to obtain a saturated solution of TNT. Then add a sufficient amount of TNCB, stir, dissolve, and filter, and the obtained filtrate is a saturated solution of TNT-TNCB co-crystallization. Put the filtrate in a petri dish, then put it still in a thermostat at 30°C, let the solvent evaporate, precipitate crystals, and dry to obtain TNT / TNCB eutectic explosive.

Embodiment 2

[0033] At room temperature, 50ml of ethanol was added into the three-necked flask, and then a sufficient amount of TNT was added under stirring, dissolved and filtered to obtain a saturated solution of TNT. Then add a sufficient amount of TNCB, stir, dissolve, and filter, and the obtained filtrate is a saturated solution of TNT-TNCB co-crystallization. Put the filtrate in a beaker, then place it still in a thermostat at 35°C, let the solvent evaporate, precipitate crystals, and dry to obtain TNT / TNCB eutectic explosive.

Embodiment 3

[0035] At room temperature, 60ml of absolute ethanol was added into a three-necked flask, and then a sufficient amount of TNT was added under stirring, dissolved and filtered to obtain a saturated solution of TNT. Then add a sufficient amount of TNCB, stir, dissolve, and filter, and the obtained filtrate is a saturated solution of TNT-TNCB co-crystallization. Put the filtrate in a beaker, then place it still in a thermostat at 35°C, let the solvent evaporate, precipitate crystals, and dry to obtain TNT / TNCB eutectic explosive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com