A kind of preparation method of high-purity cyclohexyl peptide compound

A cyclohexyl peptide and compound technology, which is applied in the field of preparation of cyclohexyl peptide compound FR179642, can solve the problems of unsuitability for large-scale industrial production, increase of operation steps and production costs, threats to the health of operators, etc., and achieve favorable quality Control, reduce process operation and equipment requirements, improve the effect of product color and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Contains 22.7L of FR179642 fermentation broth, and the fermentation unit is 700μg / ml. Add 1kg diatomaceous earth to it, stir

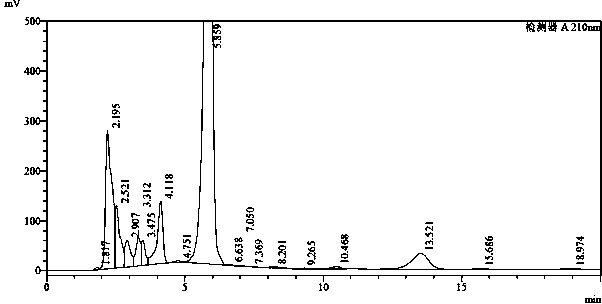

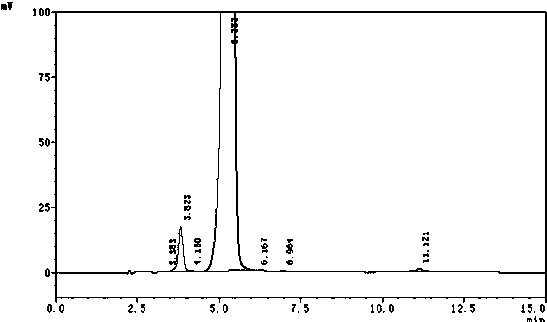

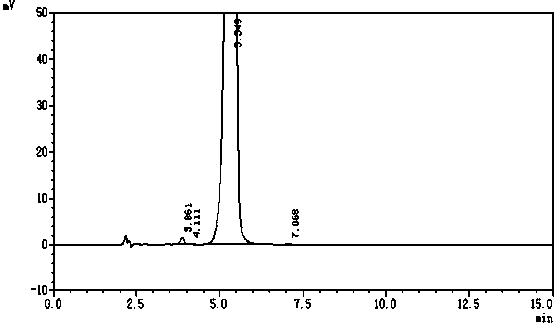

[0045] Centrifugal separation after half an hour, obtain 18.9L filtrate (the collection of illustrative plates of HPLC sees figure 1 and Table 1). The filtrate was concentrated by flash evaporation to obtain 3.8 L of concentrated solution, the unit of which was 3642 μg / ml. The concentrated solution is introduced into XAD1600 adsorption resin (φ8*80cm), the loading volume is 1500ml, and the sample loading flow rate is 2700ml / h. The resin was washed with 12L of purified water at a flow rate of 1800ml / h, and then desorbed with 12L of 5% aqueous ethanol at a flow rate of 2700ml / h. A desorption fraction was collected every 300 ml, and the fractions with a purity above 90% were mixed to obtain 7.2 L of desorption mixture. Add 7.2 g of activated carbon for 767 needles to the desorption mixture, stir for 30 minutes and then filter to obtain a decolo...

Embodiment 2

[0050] The fermentation broth FR179642 was put into a tank of 73.6L, and the fermentation unit was 628μg / ml. Add 1.5kg diatomaceous earth therein, after stirring for half an hour, plate and frame pressure filtration obtains 62.1L filtrate (HPLC peak type and figure 1 resemblance). The filtrate was concentrated by rotary evaporation to obtain a concentrated solution of 13.3 L with a fermentation unit of 3642 μg / ml. The concentrated solution was introduced into XAD1600 adsorption resin (φ 15*100cm), the filling capacity was 3.4L, and the sample loading flow rate was 10.8L / h. The resin was washed with 80 L of purified water at a flow rate of 13.2 L / h, and then desorbed with 26 L of 5% acetone aqueous solution at a flow rate of 13.2 ml / h. A desorption component was collected every 600ml, and the components with a purity of more than 90% were mixed to obtain 22.4L of desorption mixture. Add 20 g of activated carbon for 767 needles in the desorption mixed solution, stir and decol...

Embodiment 3

[0052] The fermentation broth FR179642 was put into a tank of 4.9L, and the fermentation unit was 1350μg / ml. Add 0.2kg perlite wherein, after stirring for half an hour, suction filtration separates, obtains 4.7L filtrate (HPLC peak type and figure 1 resemblance). The filtrate was concentrated by flash evaporation to obtain 1.5 L of concentrated liquid, and the fermentation unit was 4410 μg / ml. The concentrated solution was introduced into XAD1180 adsorption resin (φ4*50cm), the filling volume was 790ml, and the sample loading flow rate was 1000ml / h. The resin was washed with 4L of purified water at a flow rate of 1000ml / h, and then desorbed with 15L of 15% aqueous ethanol at a flow rate of 800ml / h. A desorption fraction was collected every 200 ml, and the fractions with a purity above 90% were mixed to obtain 1.4 L of desorption mixture. Add 1.5 g of activated carbon for 767 needles to the desorption mixture, stir and decolorize for 25 minutes, and then filter to obtain a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com