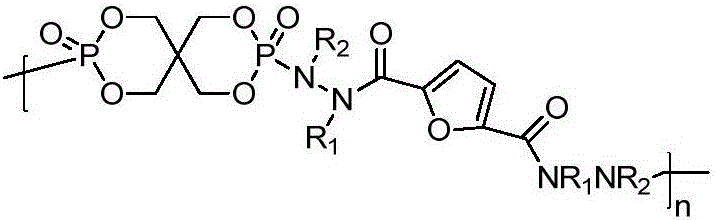

Furan bio-based antibacterial and anti-yellowing multifunctional fabric flame retardant containing N-type and P-type polymers as well as preparation method and application of fabric flame retardant

A bio-based, anti-yellowing technology, which is applied in the treatment of flame-retardant fibers, plant fibers, and biochemical fibers, can solve problems such as environmental pollution, climate change, energy crisis, and the limited number of non-renewable resources, and achieve important environmental protection and The effect of circular economy meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

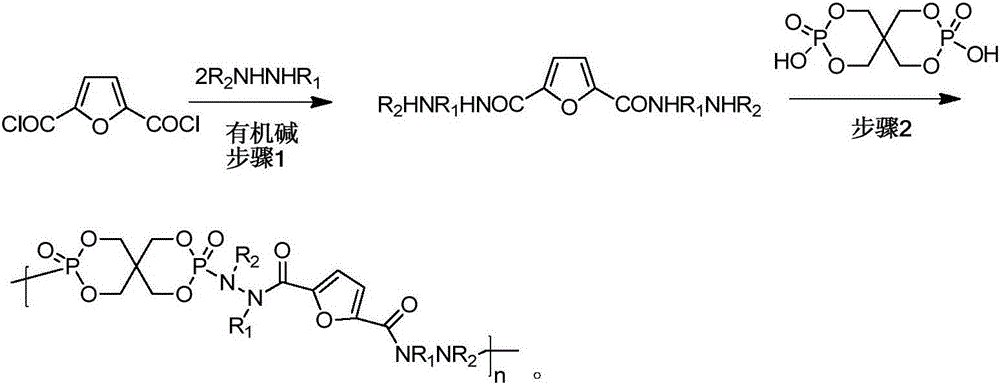

Method used

Image

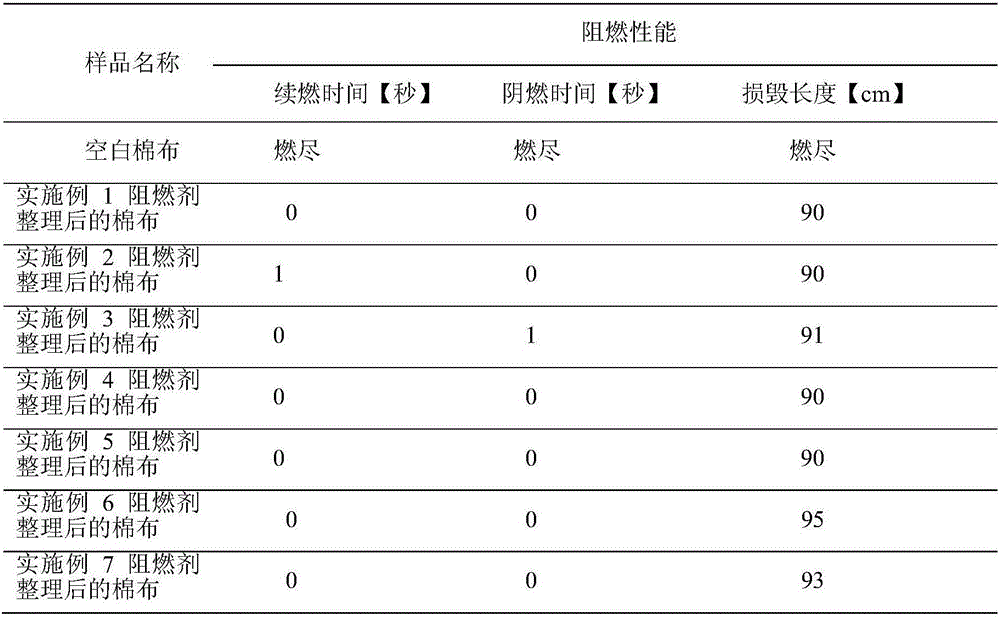

Examples

Embodiment 1

[0029] Step 1: In a 2-liter four-necked round-bottomed flask equipped with a stirrer, a thermometer and a dropping funnel, first add 2 mol of NH 2 NH 2 .H 2 O, 2mol triethylamine and 100ml dichloromethane, then add 1mol at 20°C Then continue to keep warm at 20°C for 10 hours, and finally remove the organic solvent by distillation under reduced pressure to obtain The reaction is an exothermic reaction.

[0030] Step 2: First mix 1mol with 1mol Mix in 100 ml of toluene at 20°C, then stir at 70°C for 10 hours, and finally distill the organic solvent under reduced pressure to obtain where n=125.

[0031] The physical constants of the final product of this embodiment are: 1H NMR (400MHz, CDCl3) δ7.02 (br, 1H), 6.58 (br, 1H), 5.07 (s, 8H).. Infrared spectrum (KBr tablet): 3350 , 2946, 1658, 1430, 918, 824cm-1. Elemental analysis calculated value: C, 31.00; H, 3.78; N, 13.15; found value: C, 31.21; H, 3.89; N, 13.10.

Embodiment 2

[0033] Step 1: In a 2-liter four-necked round-bottomed flask equipped with a stirrer, a thermometer and a dropping funnel, first add 2 mol of NH 2 NH 2 .H 2 O, 2mol triethylamine and 100ml dichloromethane, then add 1mol at 20°C Then continue to keep warm at -20°C for 10 hours, and finally remove the organic solvent by distillation under reduced pressure to obtain The reaction is an exothermic reaction.

[0034] Step 2: First mix 1mol with 1mol Mixed in 100 ml of toluene at 20°C, then stirred at 160°C for 10 hours, and finally distilled the organic solvent under reduced pressure to obtain where n=150.

[0035] The physical constant of present embodiment final product is the same as embodiment 1

Embodiment 3

[0037] Step 1: In a 2-liter four-neck round bottom flask equipped with a stirrer, a thermometer and a dropping funnel, first add 10mol NH 2 NH 2 .H 2 O, 2mol triethylamine and 100ml dichloromethane, then add 1mol at 20°C Then continue to incubate at -20°C for 10 hours, and finally remove the organic solvent and excess NH by distillation under reduced pressure. 2 NH2 .H 2 O get The reaction is an exothermic reaction.

[0038] Step 2: First mix 1mol with 1mol Mixed in 100 ml of toluene at 20°C, then stirred at 160°C for 10 hours, and finally distilled the organic solvent under reduced pressure to obtain n=165.

[0039] . The physical constant of present embodiment final product is the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com