Method for preparing super-hydrophobic fabric@nickel and cobalt double hydroxide composite material and its application

A technology of double hydroxide and composite materials, applied in chemical instruments and methods, separation methods, grease/oily substances/suspton removal devices, etc., can solve the problem of limited types of oily sewage, poor chemical resistance, and separation efficiency No advanced problems, to achieve the effect of simple and easy preparation method, good mechanical properties and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

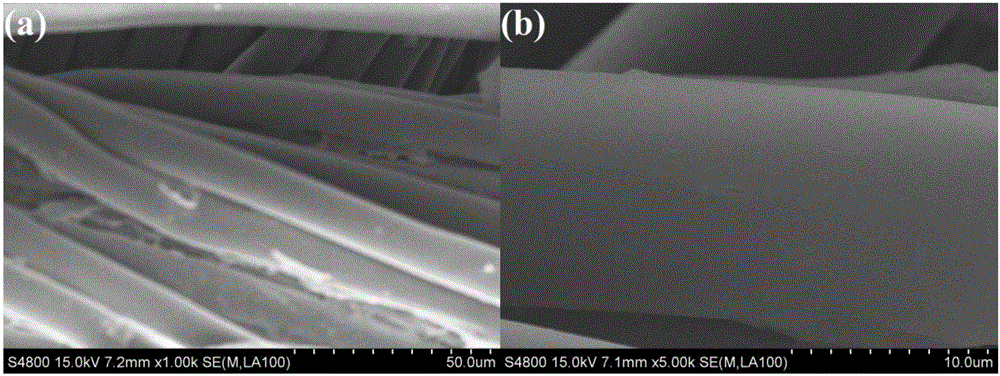

[0026] (1) Fabric pretreatment: take an appropriate amount of cotton fabrics, wash them with ethanol and deionized water, and dry them in an oven for subsequent use;

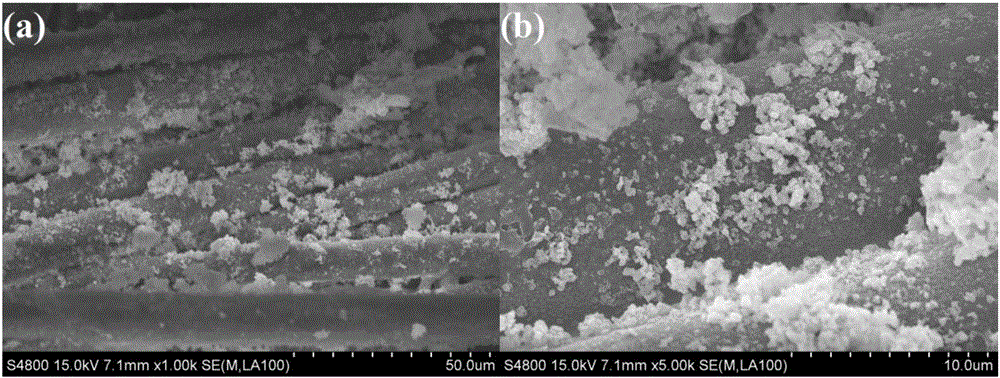

[0027] (2) Fabrication@nickel-cobalt double hydroxide preparation: 2.5mmol nickel chloride (NiCl 2 ·6H 2 O), 5mmol cobalt chloride (CoCl 2 ·6H 2 O), 2mmol cetyltrimethylammonium bromide (CTAB) and 9mmol urea (CO(NH 2 ) 2 ) was dissolved in 50 mL of deionized water. Then transfer the solution to a 100 mL three-neck flask, put a piece of fabric into the flask, and put it into a microwave-ultrasonic-ultraviolet combined catalytic synthesizer for microwave treatment (80°C, microwave 500W) for 30min. After the reaction is complete, the product is taken out, washed with ethanol, and dried at 60°C to obtain fabric@nickel-cobalt double hydroxide; the size of the cotton fabric used can be determined according to the volume of the flask, which is 4cm*4cm in the present invention.

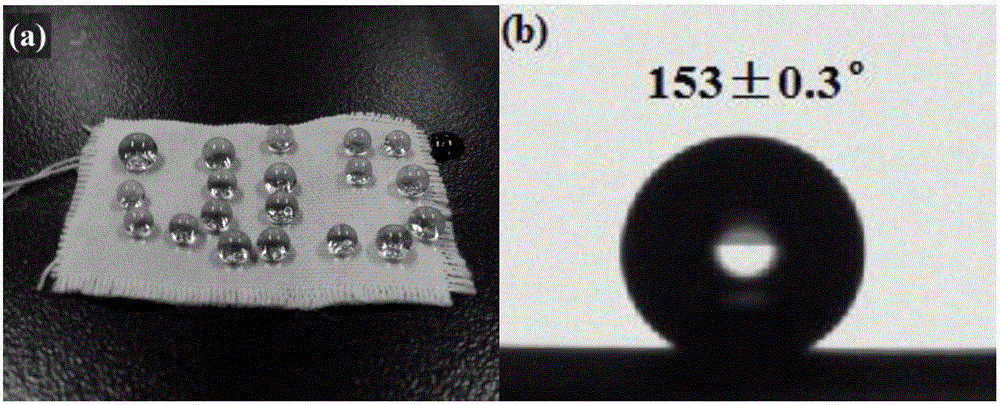

[0028] (3) Preparation of superhyd...

Embodiment 2

[0033] (1) Fabric pretreatment: take an appropriate amount of cotton fabrics, wash them with ethanol and deionized water, and dry them in an oven for subsequent use;

[0034] (2) Fabrication@nickel-cobalt double hydroxide preparation: 2.5mmol nickel chloride (NiCl 2 ·6H 2 O), 5mmol cobalt chloride (CoCl 2 ·6H 2 O), 2mmol cetyltrimethylammonium bromide (CTAB) and 9mmol urea (CO(NH 2 ) 2 ) was dissolved in 50 mL of deionized water. Then transfer the solution to a 100 mL three-neck flask, put a piece of fabric into the flask, and put it into a microwave-ultrasonic-ultraviolet combined catalytic synthesizer for microwave treatment (100°C, microwave 500W) for 20 minutes. After the reaction is complete, the product is taken out, washed with ethanol, and dried at 60°C to obtain fabric@nickel-cobalt double hydroxide; the size of the cotton fabric used can be determined according to the volume of the flask, which is 4cm*4cm in the present invention.

[0035] (3) Preparation of supe...

Embodiment 3

[0037] (1) Fabric pretreatment: take an appropriate amount of cotton fabrics, wash them with ethanol and deionized water, and dry them in an oven for subsequent use;

[0038] (2) Fabrication@nickel-cobalt double hydroxide preparation: 2.5mmol nickel chloride (NiCl 2 ·6H 2 O), 5mmol cobalt chloride (CoCl 2 ·6H 2 O), 2mmol cetyltrimethylammonium bromide (CTAB) and 9mmol urea (CO(NH 2 ) 2 ) was dissolved in 50 mL of deionized water. Then transfer the solution to a 100mL three-neck flask, put a piece of fabric into the flask, and put it into a microwave-ultrasonic-ultraviolet combined catalytic synthesizer for microwave treatment (120°C, microwave 500W) for 10min. After the reaction is complete, the product is taken out, washed with ethanol, and dried at 60°C to obtain fabric@nickel-cobalt double hydroxide; the size of the cotton fabric used can be determined according to the volume of the flask, which is 4cm*4cm in the present invention.

[0039] (3) Preparation of superhyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com