Refining method of novel menthol

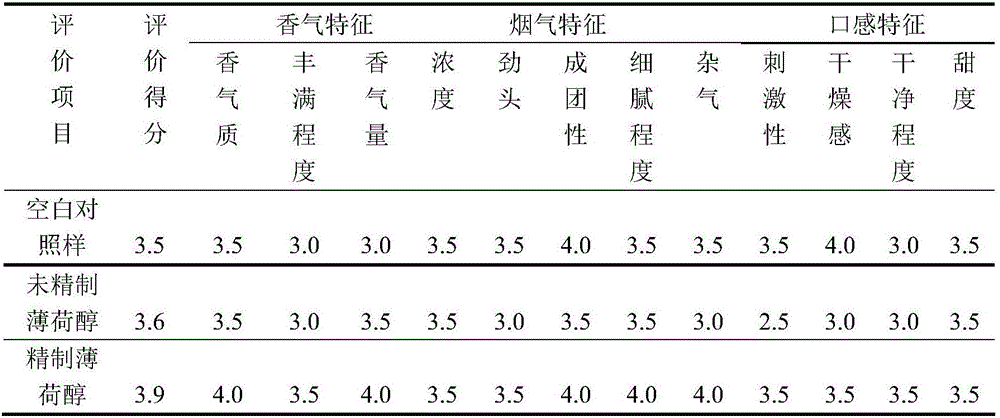

A refining method and menthol technology, applied in directions such as being fixed on/in an organic carrier, fermentation, etc., can solve the problems of free enzyme survival temperature, narrow pH value range, easy inactivation and denaturation, insufficient stability and the like, To achieve the effect of good smoke effect, high optical purity and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Take ethyl acetate and menthol with a molar ratio of 1:1, dissolve it in absolute ethanol with 4.5 times the total mass of ethyl acetate and menthol, heat and reflux for 10 hours, and spin off the solvent after stopping the reaction Ethanol, obtains thick product, elutes 3 times with distilled water, obtains menthyl ester;

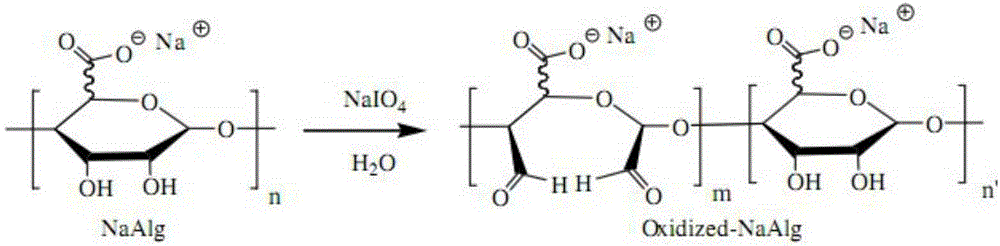

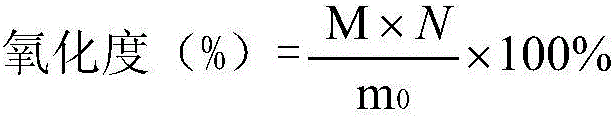

[0028] (2) Take sodium alginate, add 50 times its weight in distilled water, oscillate to dissolve, then add 1.2% of its weight in sodium periodate, and react in the dark at 4°C for 24 hours to obtain oxidized sodium alginate, and the obtained oxidized The degree of oxidation of sodium alginate is 0.9%;

[0029] (3) Drop the oxidized sodium alginate into 2% calcium chloride solution of 10 times its mass, soak for 35 minutes, wash with distilled water 3 times and dialyze, and filter to obtain calcium alginate microspheres;

[0030] (4) Take 10 mg of lipase, add / 0.1 g calcium alginate microspheres obtained in step (3), dissolve in a buffer soluti...

Embodiment 2

[0033](1) Take ethyl acetate and menthol with a molar ratio of 1.4:1, dissolve it in dehydrated ethanol with 4.5 times the total mass of ethyl acetate and menthol, heat and reflux for 10 hours, stop the reaction and spin off the solvent Ethanol, obtains thick product, elutes 3 times with distilled water, obtains menthyl ester;

[0034] (2) Take sodium alginate, add 50 times its weight in distilled water, oscillate to dissolve, then add 5.4% of its weight in sodium periodate, and react in the dark at 4°C for 24 hours to obtain oxidized sodium alginate, and the obtained oxidized The degree of oxidation of sodium alginate is 4.7%;

[0035] (3) Drop the oxidized sodium alginate into 3% calcium chloride solution of 20 times its mass, soak for 50 min, wash with distilled water 3 times and dialyze, and filter to obtain calcium alginate microspheres;

[0036] (4) Take 16 mg of lipase, add 0.1 g of the calcium alginate microspheres obtained in step (3), dissolve in a buffer solution o...

Embodiment 3

[0039] (1) Take ethyl acetate and menthol with a molar ratio of 2:1, dissolve it in absolute ethanol with 4.5 times the total mass of ethyl acetate and menthol, heat and reflux for 10 hours, and spin off the solvent after stopping the reaction Ethanol, obtains thick product, elutes 3 times with distilled water, obtains menthyl ester;

[0040] (2) Take sodium alginate, add 50 times its weight of distilled water, shake and dissolve, then add 10% of its weight of sodium periodate, and react in the dark at 4°C for 24 hours to obtain oxidized sodium alginate, and the obtained oxidized The degree of oxidation of sodium alginate is 9.5%;

[0041] (3) Drop oxidized sodium alginate into 4% calcium chloride solution of 50 times its mass, soak for 55 minutes, wash with distilled water 3 times and dialyze, and filter to obtain calcium alginate microspheres;

[0042] (4) Get 26mg of lipase, add 0.1g of calcium alginate microspheres obtained in step (3), dissolve in a buffer solution of pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com