Titanium-containing powder for blast furnace protection and furnace protection method for injection through blast furnace coal injection system

A blast furnace protection and blast furnace coal injection technology, which is applied in the field of blast furnace protection and titanium-containing powder for blast furnace protection, can solve the problems of small application range, damage to the uniformity and stability of blast furnace hearth, and achieve short onset time. , to avoid adverse effects, the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

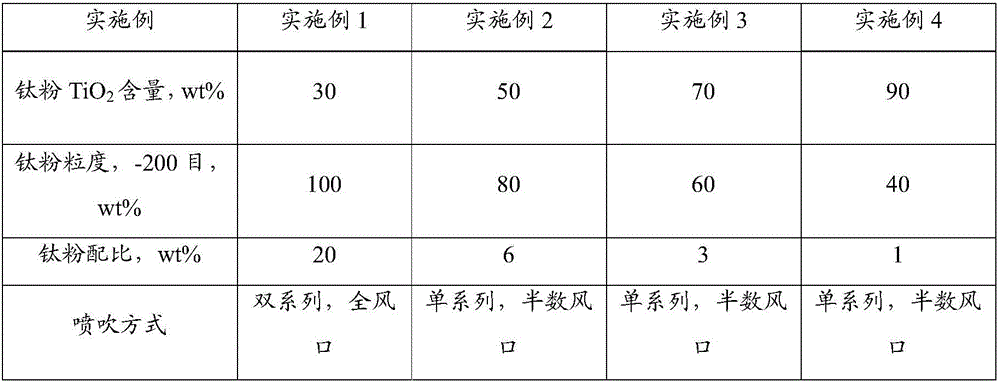

[0022] The present invention is further described below in conjunction with embodiment.

[0023] Titanium-containing powder for blast furnace protection of the present invention, TiO in the titanium-containing powder 2 The content is 30-90 wt%, and the particle size of less than 200 mesh accounts for 40-100 wt%. The titanium-containing powder is sprayed into the blast furnace together with coal powder through the blast furnace coal injection system. When the titanium-containing powder is sprayed into the blast furnace, the proportion of the titanium-containing powder is 1% to 20wt%, and the rest is coal powder. The titanium-containing powder is processed from ilmenite lump ore, rutile, high-titanium slag, vanadium-titanium iron concentrate or titanium concentrate.

[0024] The present invention utilizes blast furnace coal injection system to inject titanium-containing powder blast furnace protection furnace method to comprise the following steps:

[0025] (1) Mix titanium-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com