Method for improving mechanical properties of butylated hydroxy propellant and prepared butylated hydroxy propellant

A technology of butyl-hydroxy propellant and propellant, which is applied in the field of rocket propulsion and missile weapons to achieve good compatibility, improve process performance and aging performance, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

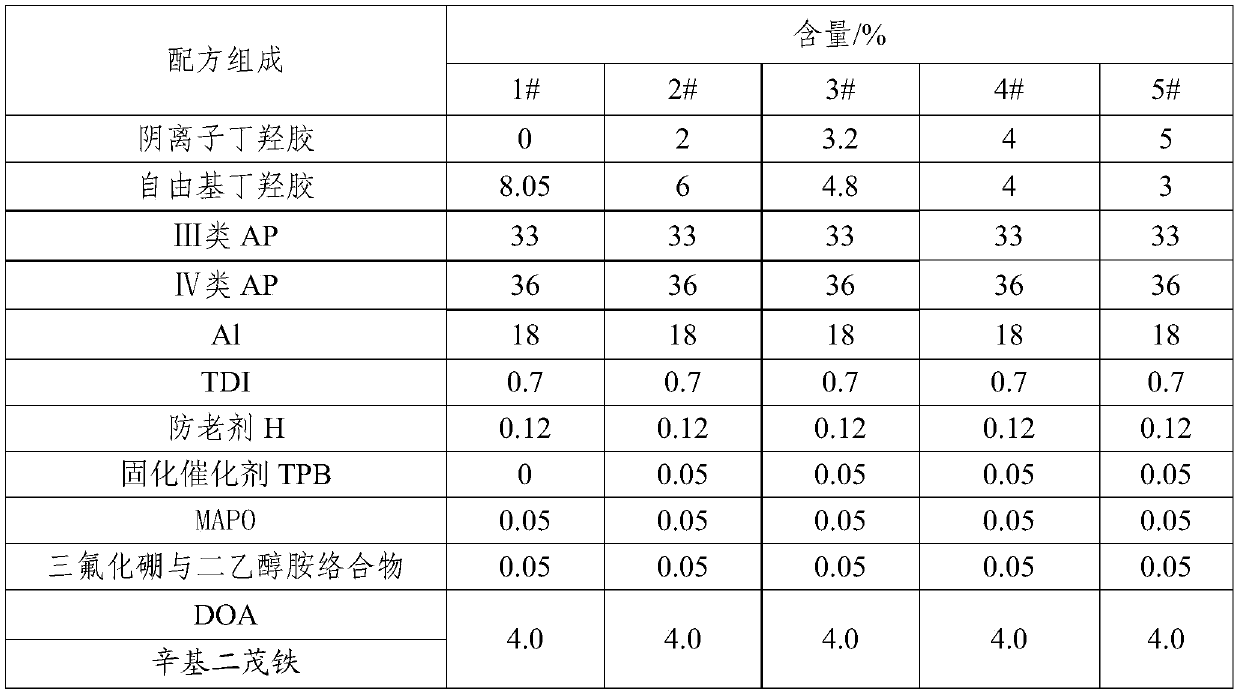

[0034] The anionic butylated hydroxyl gum with the same relative molecular mass was substituted for different amounts of free radical butylated hydroxyl gum. The specific composition of the propellant formula is shown in Table 1.

[0035] Table 1 Propellant formulation composition

[0036]

[0037] Note: The relative molecular mass of the anionic glue in the formulations of 2#, 3#, 4#, and 5# is 5.68×10 3

[0038] The various performance results of table 2 propellant

[0039]

[0040] It can be seen from Table 2 that the mechanical properties of the propellant added with anionic butylated hydroxy rubber and curing catalyst are significantly better than those of the propellant formulation without anionic butylated hydroxy rubber, and the anionic butylated hydroxy rubber has no effect on the burning rate of the propellant. At the same time, it has good aging performance.

Embodiment 2

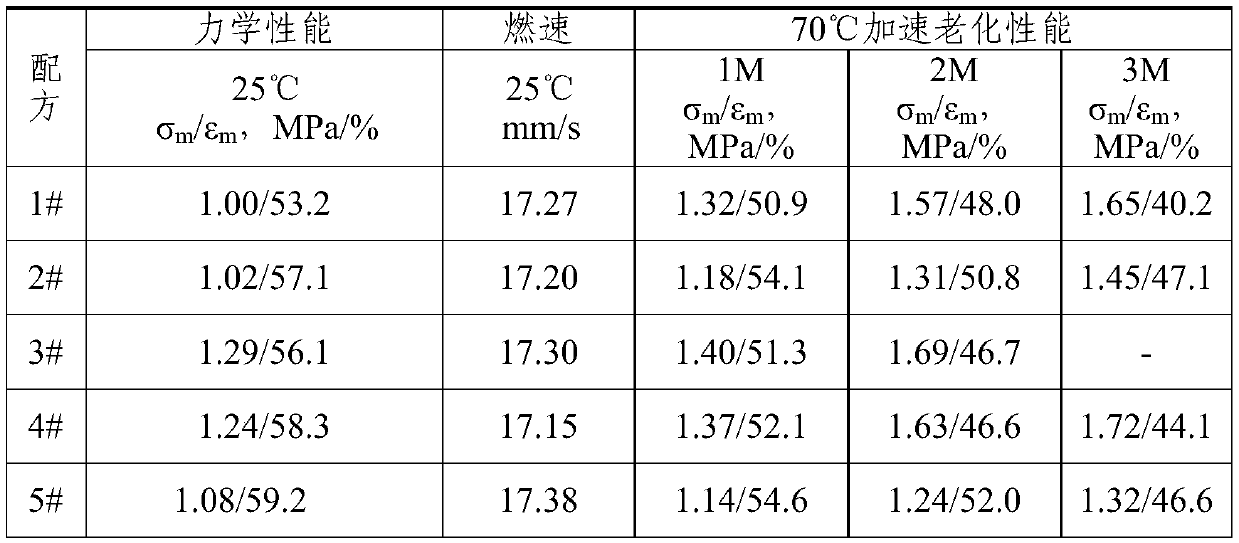

[0042] Anionic butylated hydroxyl gums with different relative molecular weights were selected to replace free radical butylated hydroxyl gums. The relative molecular masses of anions are shown in Table 3.

[0043] The relative molecular mass of table 3 anionic butylated hydroxyl gum

[0044] Numbering AHTPB-1 AHTPB-2 AHTPB-3 relative molecular mass 2.66×10 3

5.68×10 3

6.49×10 3

[0045] The specific composition of the propellant formula is shown in Table 4.

[0046] Table 4 Propellant formulation composition

[0047]

[0048] Table 5 The results of the mechanical properties of the propellant

[0049]

[0050] It can be seen from Table 5 that the normal, high and low temperature mechanical properties of propellants added with different molecular weights of anionic butyl rubber and curing catalysts are better than those of propellants without anionic butyl rubber.

Embodiment 3

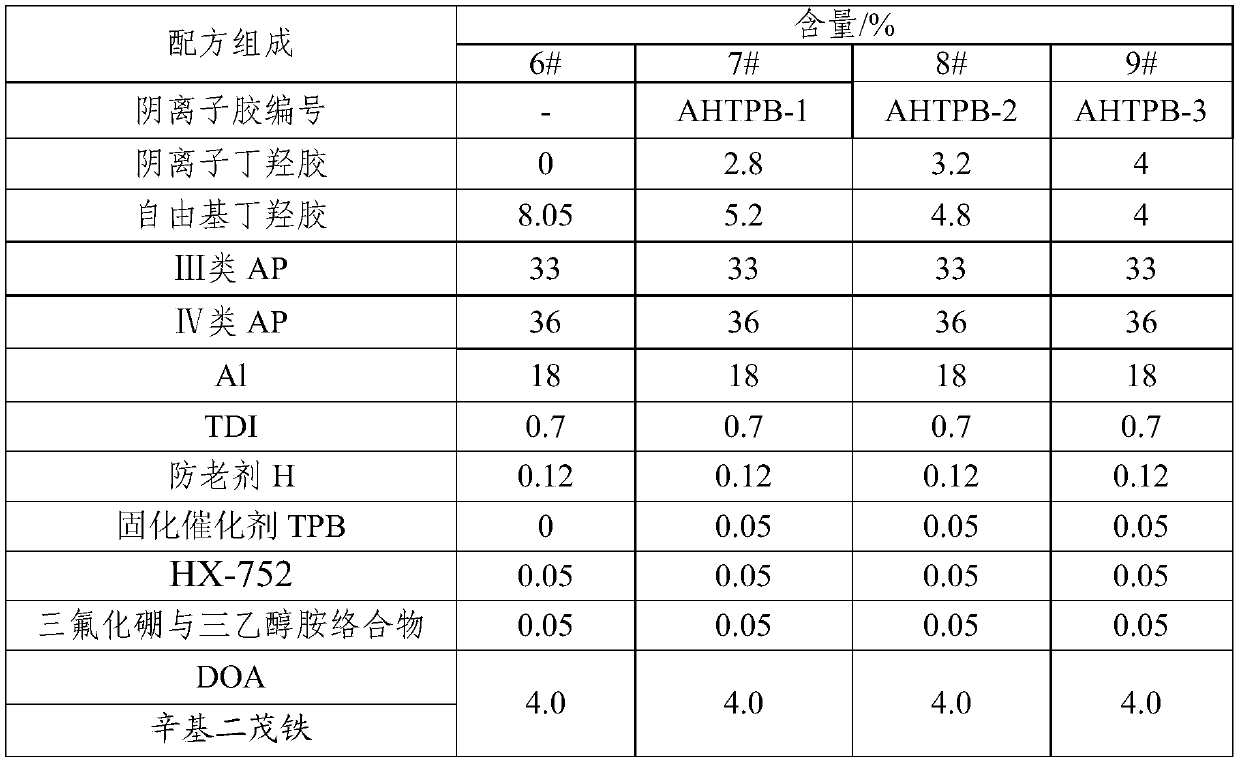

[0052] The anionic butylated hydroxyl gum with the same relative molecular mass was substituted for different amounts of free radical butylated hydroxyl gum, and the specific composition of the propellant formula is shown in Table 6.

[0053] Table 6 Propellant formulation composition

[0054]

[0055] Note: The relative molecular mass of anionic glue in 2#, 3#, and 4# formulas is 6.49×10 3 .

[0056] Table 7 The results of the mechanical properties of the propellant

[0057]

[0058] Table 8 Process performance of propellant

[0059]

[0060] Note: The propellant is kept at 50°C for 5 hours

[0061] It can be seen from Table 7 that the normal, high and low temperature mechanical properties of the propellant added with anionic butylated hydroxy rubber and curing catalyst are better than those of the propellant without anionic butylated hydroxy rubber; The viscosity of the propellant of the hydroxyl glue and the curing catalyst is significantly reduced, and the proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com