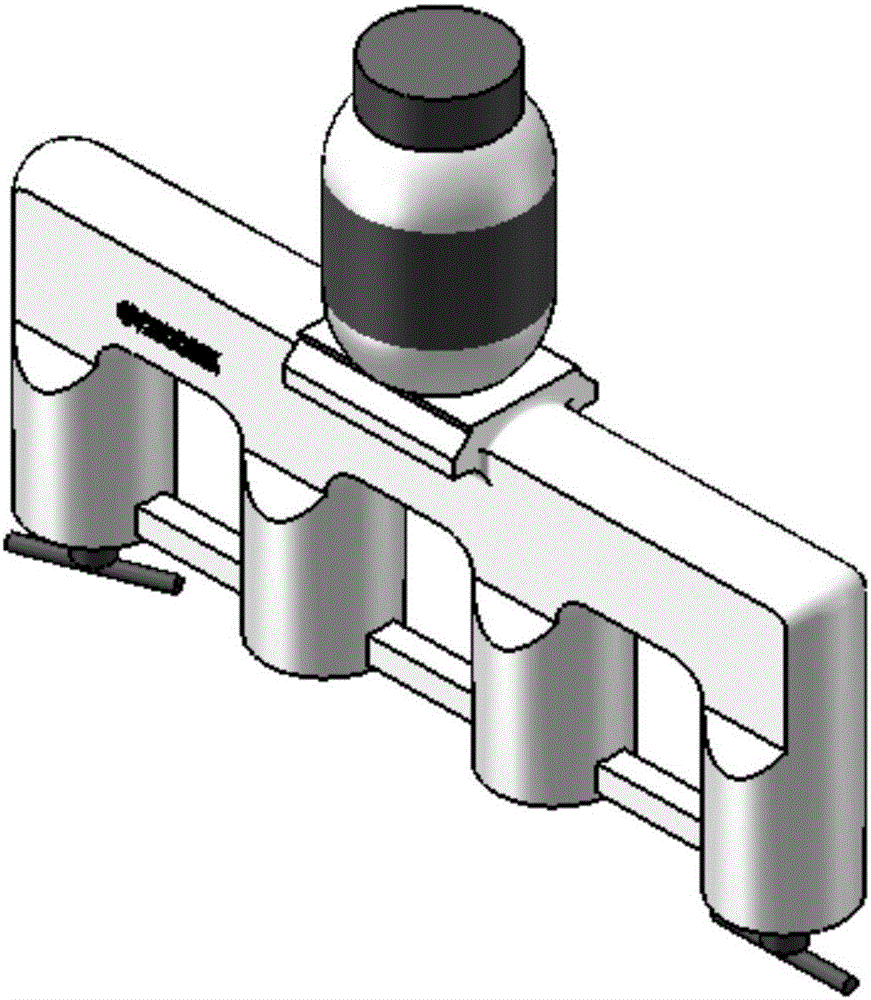

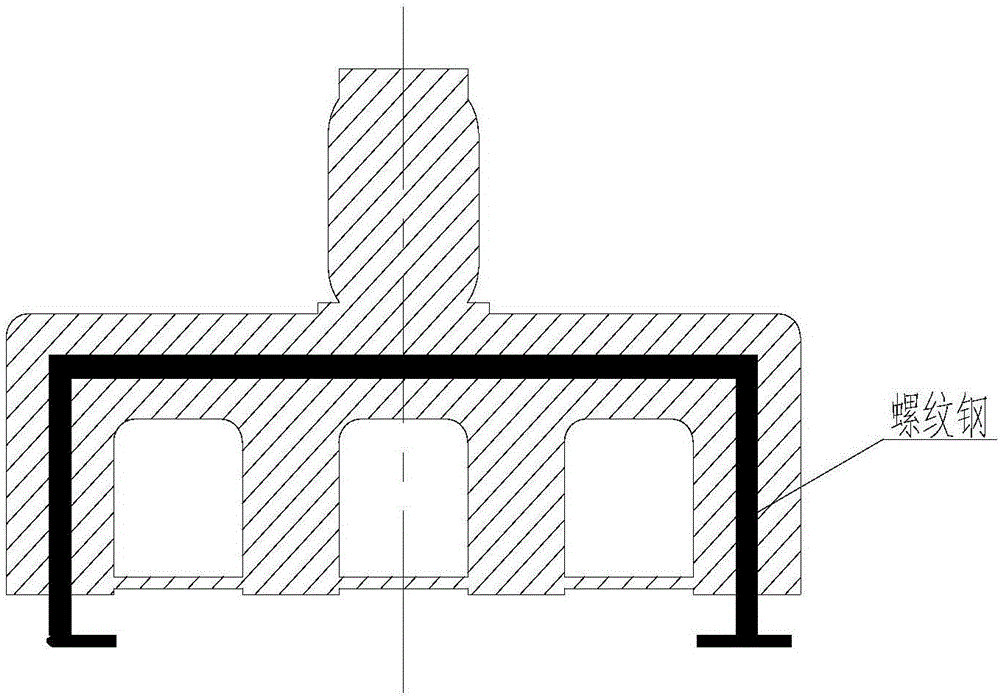

Anode steel stud for electrolytic aluminum

An anode steel claw and electrolytic aluminum technology, which is applied in the field of anode steel claw for electrolytic aluminum, can solve the problems of increased metal resistance, lattice distortion, increased heat generation, etc., and achieves improved electrical conductivity, excellent corrosion resistance, and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

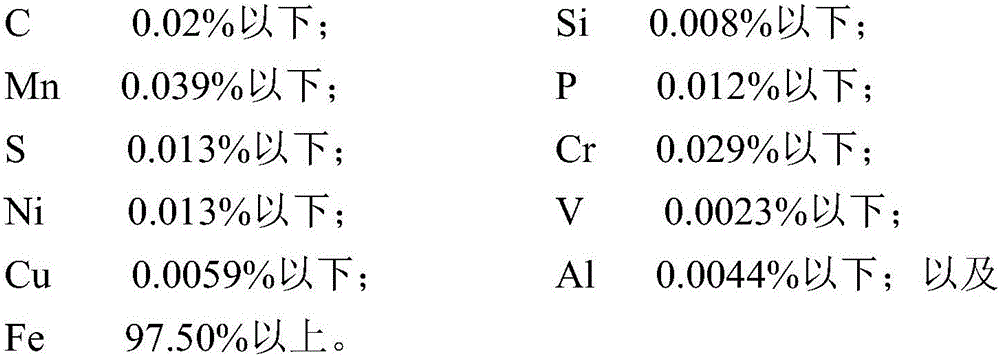

[0055] Cast pure iron in the following element content ranges is used as raw material to manufacture the anode steel claw of the present invention: C0.0075%, Si 0.004%, Mn 0.015%, P 0.0071%, S 0.0048%, Cr 0.0033%, Ni 0.0088% , V 0.0020%, Cu 0.0054%, Al 0.0030%, and Fe 99.81%.

[0056] After the above-mentioned cast pure iron is poured by lost foam casting technology, the impurity content of the obtained anode steel claw is as follows: C0.0065%, Si 0.006%, Mn 0.023%, P 0.0076%, S 0.0088%, Cr 0.0033%, Ni 0.0088 %, V 0.0019%, Cu 0.0059%, Al 0.0029% and Fe 99.80%, and the resistivity of the anode steel claw is 0.121 μΩ·m.

Embodiment 2

[0058] Cast pure iron in the following element content ranges is used as raw material to manufacture the anode steel claw of the present invention: C0.0095%, Si 0.0077%, Mn 0.038%, P 0.01%, S 0.0012%, Cr 0.0018%, Ni 0.01% , V0.0020%, Cu 0.0051%, Al 0.0030%, and Fe 99.83%.

[0059] After the above-mentioned cast pure iron is poured by the lost foam casting technology, the obtained anode steel claw contains the following elements: C 0.01%, Si 0.008%, Mn 0.039%, P 0.011%, S 0.013%, Cr 0.017%, Ni 0.013 %, V0.0023%, Cu 0.0048%, Al 0.0037% and Fe 99.82%, and the resistivity of the anode steel claw is 0.130μΩ·m.

Embodiment 3

[0061] Cast pure iron in the following element content ranges is used as raw material to manufacture the anode steel claw of the present invention: C0.0185%, Si 0.0045%, Mn 0.016%, P 0.011%, S 0.009%, Cr 0.0093%, Ni 0.0088% , V0.0017%, Cu 0.0034%, Al 0.0035%, and Fe 99.87%.

[0062] After the above-mentioned cast pure iron is poured by the lost foam casting technology, the obtained anode steel claw contains the following elements: C 0.02%, Si 0.005%, Mn 0.02%, P 0.012%, S 0.012%, Cr 0.01%, Ni 0.009 %, V0.0022%, Cu 0.004%, Al 0.004% and Fe 99.81%, and the resistivity of the anode steel claw is 0.129 μΩ·m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com