Microwave system facilitating coal mass gas desorption

A microwave system and gas technology are applied in a system for promoting gas desorption, and in the field of systems for promoting gas desorption, which can solve problems such as deteriorating working face environment, increasing mine drainage pressure, and fracturing fluid filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

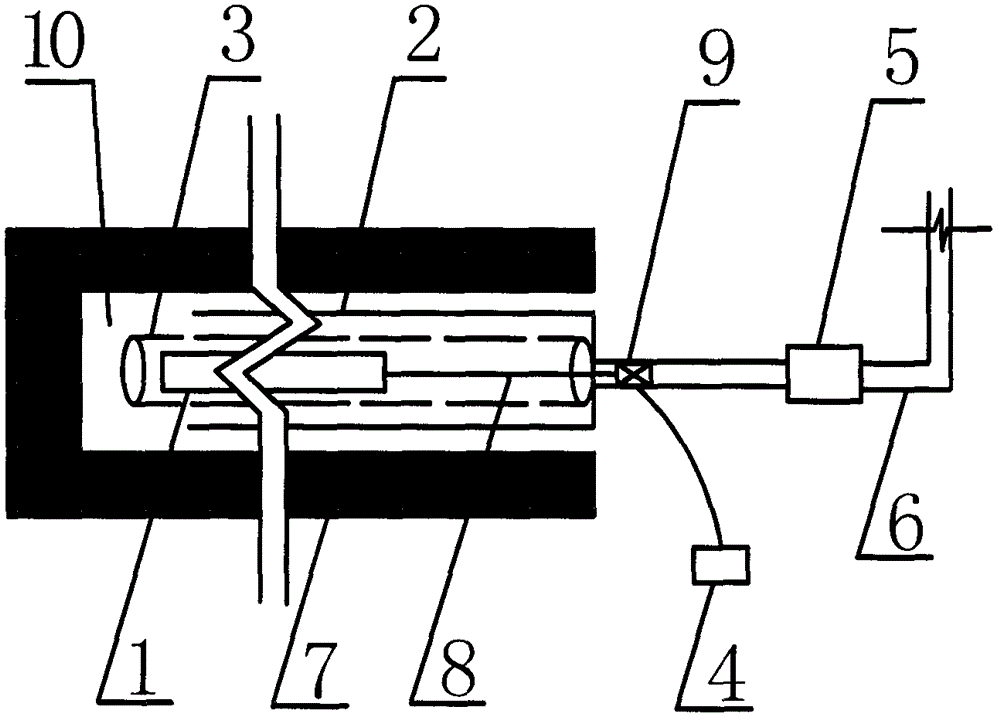

[0013] The present invention explains in detail the microwave system for promoting the desorption of coal body gas in conjunction with the accompanying drawings.

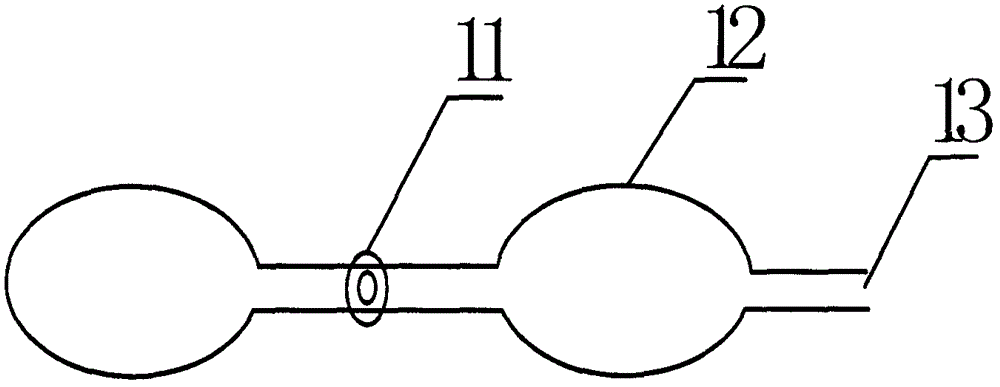

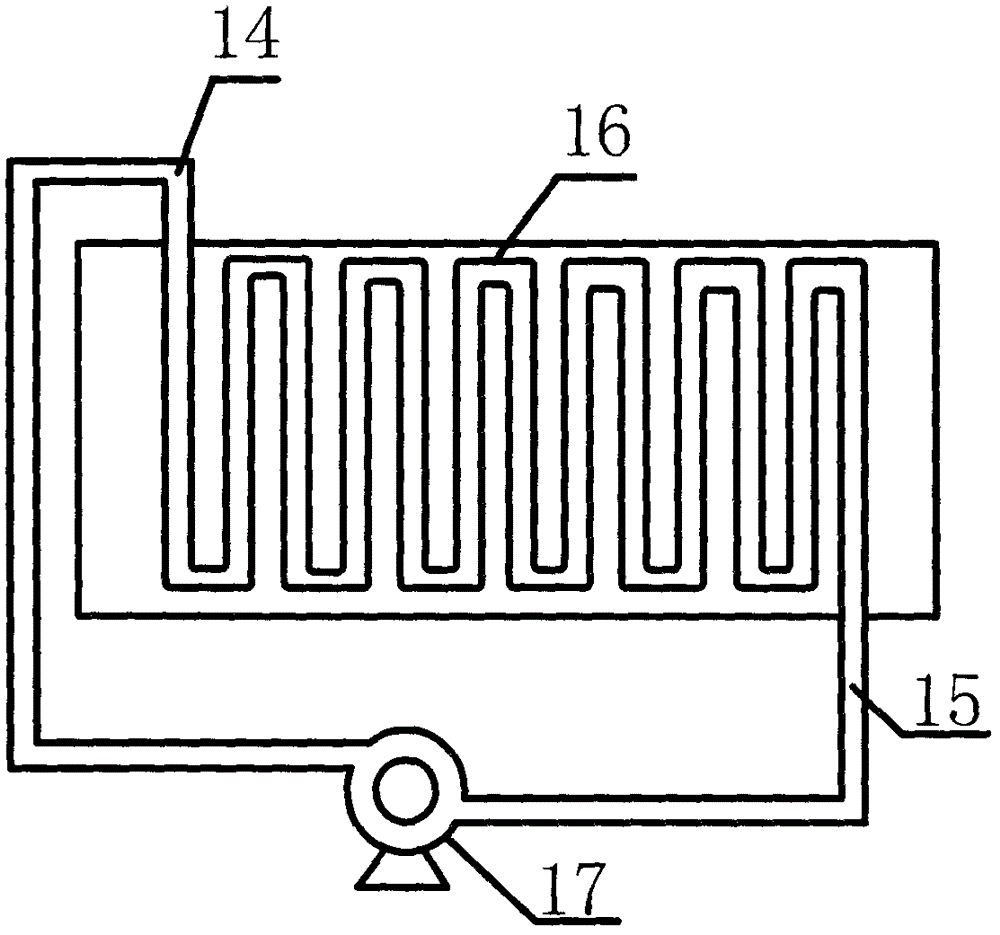

[0014] According to the accompanying drawings, the present invention has the microwave generating device (1), gas pipe (2), screen pipe (3), controller (4), circulating water cooling device (5), negative Pressure extraction pipeline (6), cable (8), pressure sensor (9), drilling (10), pressure valve (11), grouting bag (12), grouting port (13), water inlet ( 14), a water outlet (15), a circulation pipeline (16), and a cooling pump (17).

[0015] Carry out construction drilling (10) in this coal seam (7) according to the position designed in advance, and the distance between adjacent drilling holes should be determined according to the radius of action of the microwave system (1) that promotes coal gas desorption (10) ) between the spacing.

[0016] The microwave generating device (1) of the microwave system for prom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com