Three-dimensional variable-space variable-structure flue gas reheater

A flue gas reheater, variable space technology, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problem of restricting the application of flue gas reheaters, large flow resistance, low heat exchange efficiency, etc. problems, to achieve the effect of compact structure, reducing fluid resistance, and strengthening heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

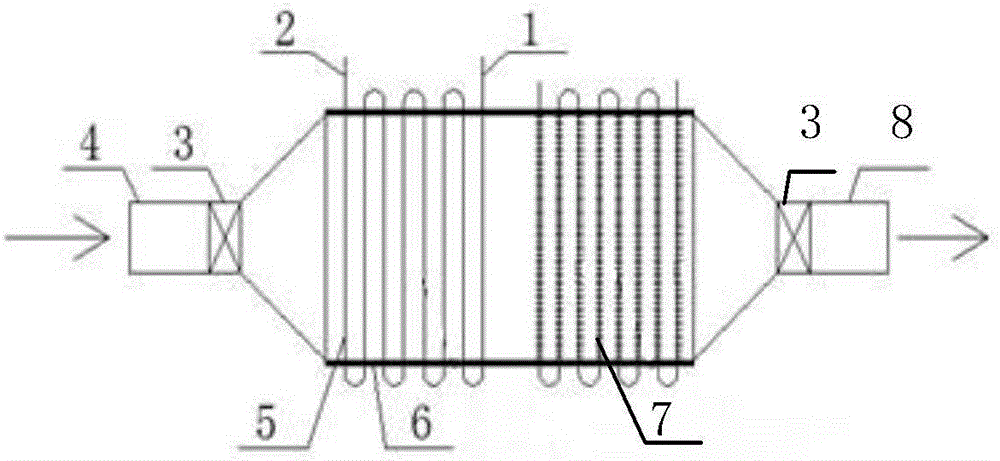

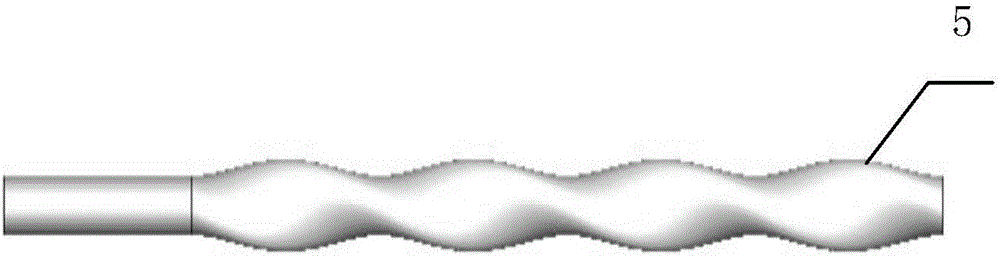

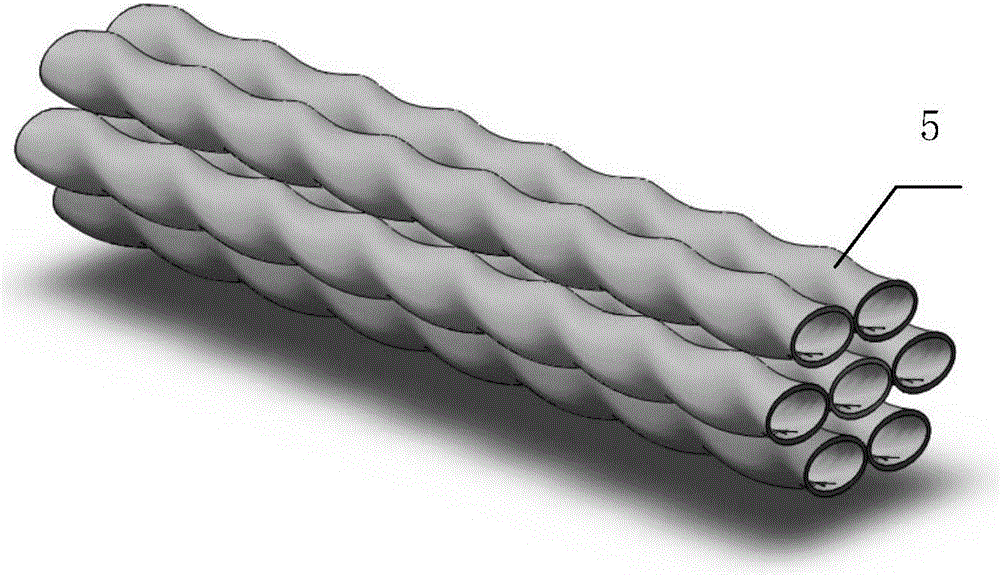

[0023] refer to Figure 1 to Figure 3 , a three-dimensional flue gas reheater with variable space and variable structure, including a flue gas channel composed of an inlet flue 4, a sealing plate 6 and an outlet flue 8, and the flue gas channel is sequentially provided with low-temperature The heat exchange tube 5 and the high-temperature heat exchange tube 7, the low-temperature heat exchange tube 5 is a three-dimensionally deformed HP tube, the three-dimensionally deformed HP tube is made of an elliptical tube twisted by a spiral, and the upstream end is provided with a heat medium water inlet 2, A heat medium water outlet 1 is provided at the downstream end, and the heat medium water outlet 1 communicates with the inlet of the high-temperature heat exchange tube 7 .

[0024] Wherein, there are multiple three-dimensionally deformed HP tubes, and the multiple three-dimensionally deformed HP tubes are in contact with each other at the maximum diameter-reducing convex point, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com