Fault tree-based numerical control machine tool fault removal scheme judgment indication method

A CNC machine tool and fault elimination technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of unfavorable diagnostic knowledge, sharing, and heavy workload of equipment maintenance and repair, so as to ensure comprehensiveness, Increased efficiency, improved accuracy, and comprehensive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] This embodiment takes the description of the fault phenomenon "a fault occurs when the tool holder is changed" as an example, and more specifically illustrates the application of the present invention's fault tree-based fault elimination scheme discrimination and indication method for CNC machine tools in the actual fault discrimination and indication process of CNC machine tools.

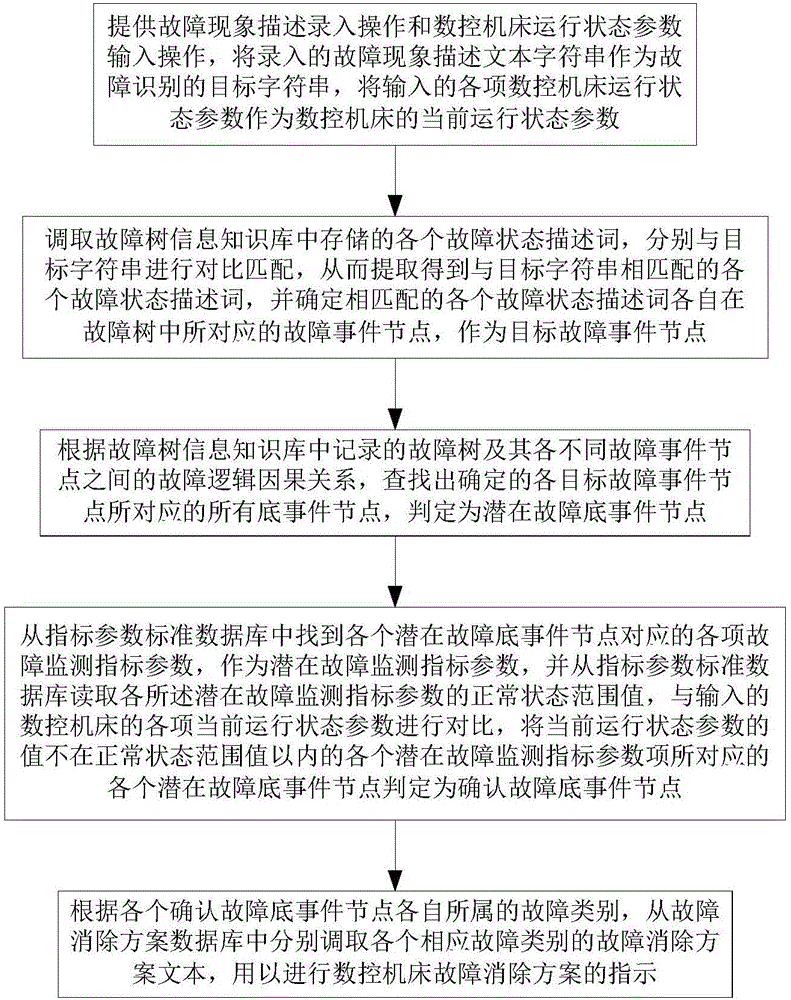

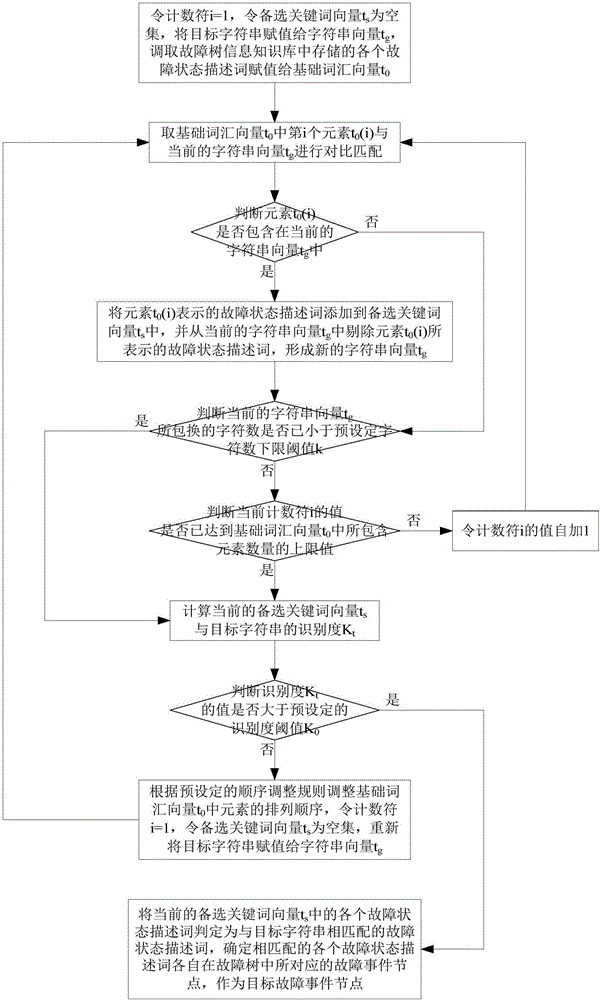

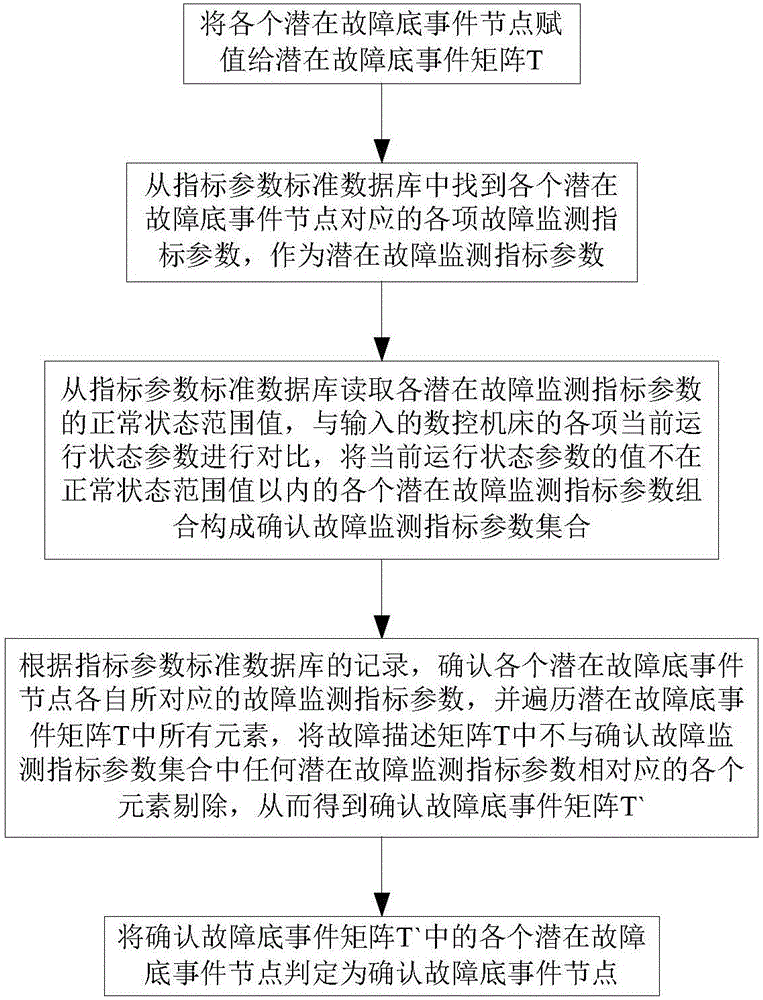

[0086] Before implementing the fault identification and indication of CNC machine tools, it is necessary to establish the fault tree information knowledge base, index parameter standard database, and fault elimination scheme database of CNC machine tools in advance. The data content recorded and stored by each of the three is as mentioned above, and will not be repeated here. ; Then, carry out the discrimination instruction to the CNC machine tool fault elimination scheme according to the following steps:

[0087] A) Provide fault phenomenon description entry operation and CNC machine tool ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com