Cured film forming resin composition

A technology of resin composition and cured film, applied in the direction of coating, etc., can solve the problems of complicated process and cost, and achieve the effect of excellent flexibility, excellent resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

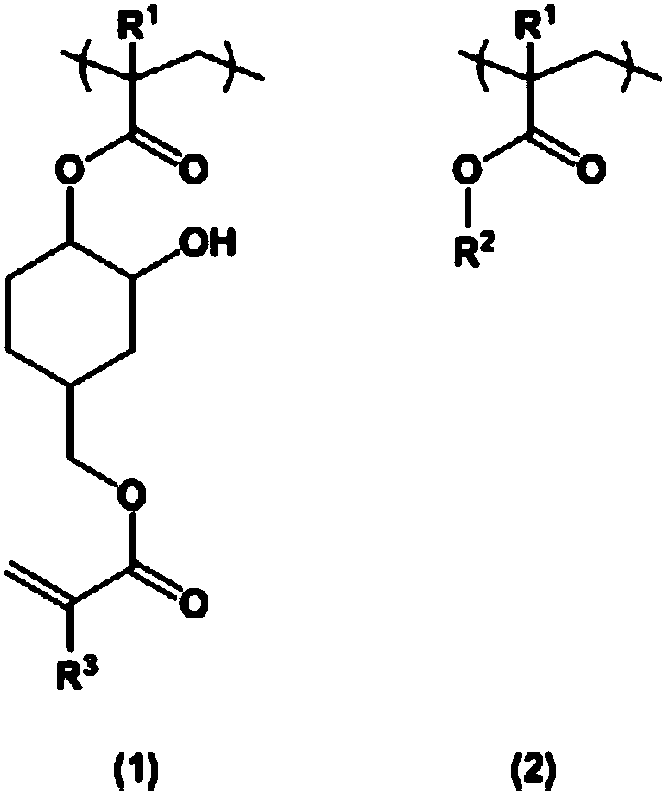

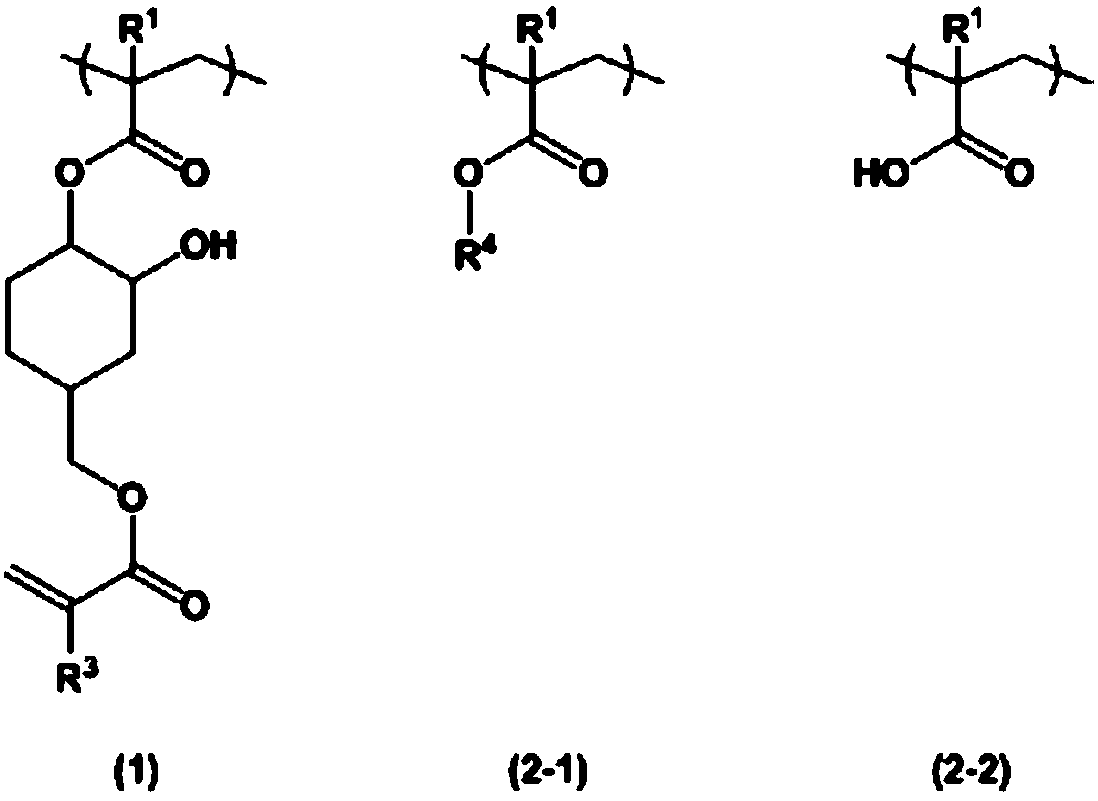

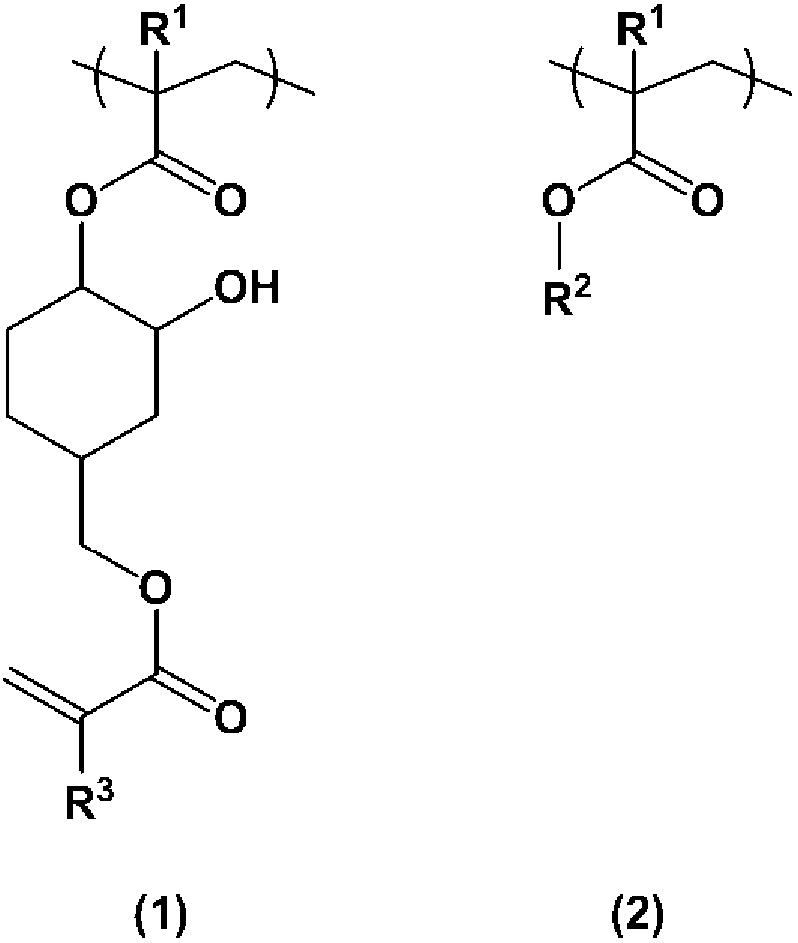

Image

Examples

preparation example Construction

[0107] [Preparation method of composition]

[0108] The method for preparing the composition of the present invention is not particularly limited. As an example, the method of dissolving (A) component in (D) solvent, mixing (B) and (C) components in a predetermined ratio in this solution in an arbitrary order to prepare a uniform solution . In addition, there may be mentioned a production method in which components (E) to (I) and other components are further added and mixed as necessary at an appropriate stage of the production method. The thus-prepared cured film-forming resin composition in a solution state is preferably used after being filtered with a filter having a pore diameter of about 0.2 µm or the like.

[0109] [Coated film and cured film]

[0110]Printing by using spin coating, flow coating, roll coating, slit coating, slit next spin coating, inkjet coating, screen printing, flexographic printing, gravure printing, offset printing, gravure offset printing, etc. ...

Embodiment 1

[0131] 41.5 g of CYCLOMER-P, 9.8 g of PET-30, 9.8 g of CYMEL303, 0.6 g of PERBUTYL L, 0.2 g of UPS, and 37.5 g of DEGEEA were charged in a 200 mL container. This was placed in a stirring device and stirred at 2,000 rpm for 10 minutes to prepare a composition (varnish).

Embodiment 2

[0133] 33.5 g of CYCLOMER-P, 11.8 g of PET-30, 11.8 g of CYMEL303, 0.5 g of PERBUTYL L, 0.2 g of UPS, and 42.2 g of DEGEEA were placed in a 200 mL container. This was placed in a stirring device and stirred at 2,000 rpm for 10 minutes to prepare a composition (varnish).

[0134] [2] Manufacture and evaluation of cured film

[0135] [2-1] Measurement of light transmittance

[0136] The varnishes of Examples 1 and 2 were respectively coated on quartz glass substrates by spin coating, and prebaked at 110°C for 2 minutes. Next, post-baking was performed at 230°C for 30 minutes to prepare a cured film with a thickness of 2 µm.

[0137] Then, the light transmittance in wavelength 400nm of each obtained cured film was measured. It should be noted that the light transmittance of the quartz glass substrate used was 93.8%.

[0138] [2-2] Evaluation of pencil hardness and adhesion

[0139] The varnishes of Examples 1 and 2 were each coated on an ITO-coated glass substrate using a ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com