Functional protein having bile acid adsorbing capacity and preparation method of functional protein

A technology of adsorption capacity and bile acid, which is applied in the field of functional proteins, can solve the problems of affecting human gastrointestinal function and side effects, and achieve the effects of improving bile acid binding capacity, high digestibility, and reducing morbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

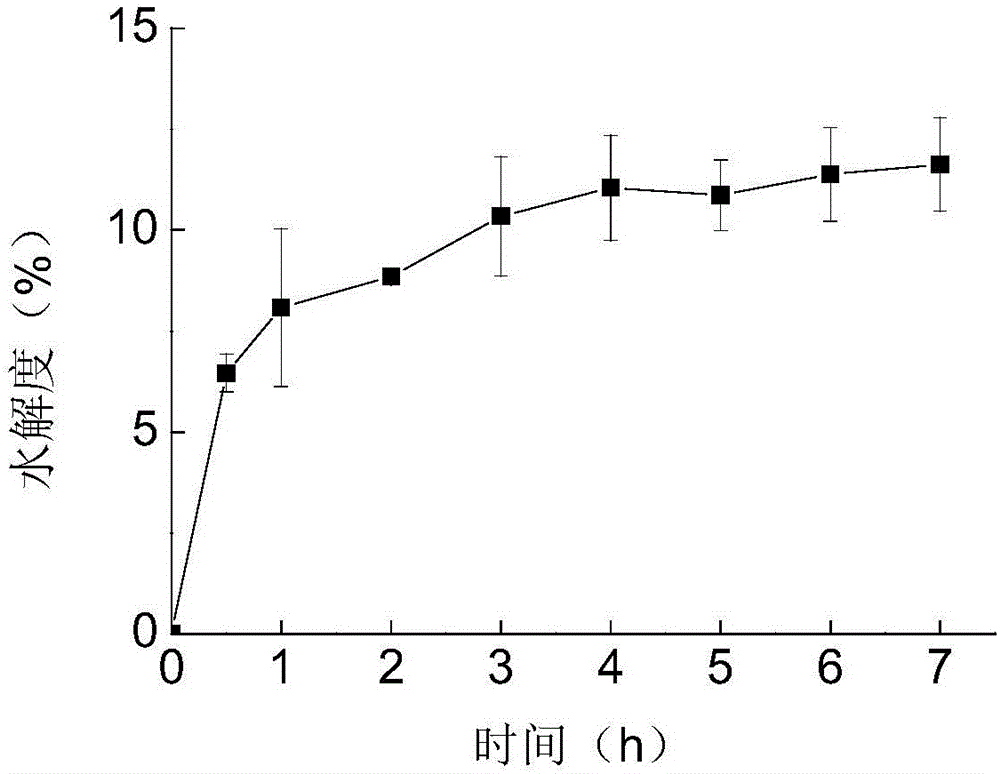

[0052] Example 1: Effects of different enzymatic hydrolysis times on the degree of hydrolysis of soybean protein

[0053] Take 4.0g soybean protein, prepare pH 2.0, 4.0% soybean protein solution with 50mmol / L phosphate buffer; heat treatment at 80°C for 10min, cool to room temperature; add 1.0KU / g 蛋白 Pepsin, enzymatic hydrolysis with stirring at 37°C. After 0.0, 0.5, 1.0, 2.0, 3.0, 4.0, 5.0, 6.0, and 7.0 hours of enzymolysis, take 5.0 mL of boiling water from the enzymolysis solution to inactivate the enzyme for 10 minutes. Cool to room temperature, adjust the pH to 4.6 with 0.1mol / L NaOH, and centrifuge at 10000r / min for 15min. The supernatant is the hydrolyzate of soybean protein, and the protein content and degree of hydrolysis in the supernatant were determined.

[0054] Such as figure 1 It was shown that the hydrolysis degree of soybean protein increased 1.0 h before enzymatic hydrolysis, and the enzymatic hydrolysis speed was fast. With the prolongation of enzymatic h...

Embodiment 2

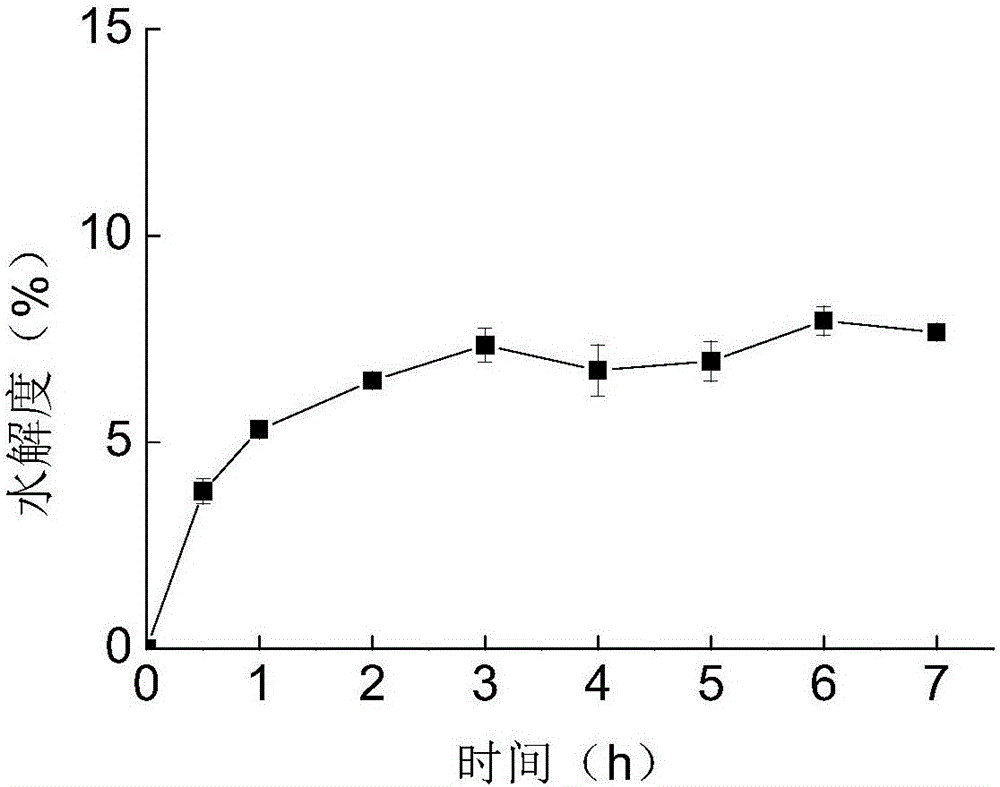

[0055] Example 2: Effects of different enzymolysis times on the degree of hydrolysis of whey protein

[0056] Take 4.0g whey protein, prepare pH 2.0, 4.0% whey protein solution with 50mmol / L phosphate buffer; heat treatment at 80°C for 10min, cool to room temperature; add 1000U / g 蛋白 Pepsin, 37 ℃ stirring enzymatic hydrolysis. After enzymatic hydrolysis for 0.0, 0.5, 1.0, 2.0, 3.0, 4.0, 5.0, 6.0, 7.0h and other different times, take 5.0mL from the enzymatic solution, inactivate the enzyme with boiling water for 10min, cool to room temperature, and centrifuge at 10000r / min for 15min. The supernatant is the enzymatic hydrolysis product of whey protein, and the degree of hydrolysis in the supernatant is determined.

[0057] Such as figure 2 As shown, the degree of hydrolysis remained basically unchanged after 3.0 h of enzymatic hydrolysis. The degree of hydrolysis tends to be stable after 5.0 hours, and the enzymatic hydrolysis time of whey protein is selected to be 5.0 hours ...

Embodiment 3

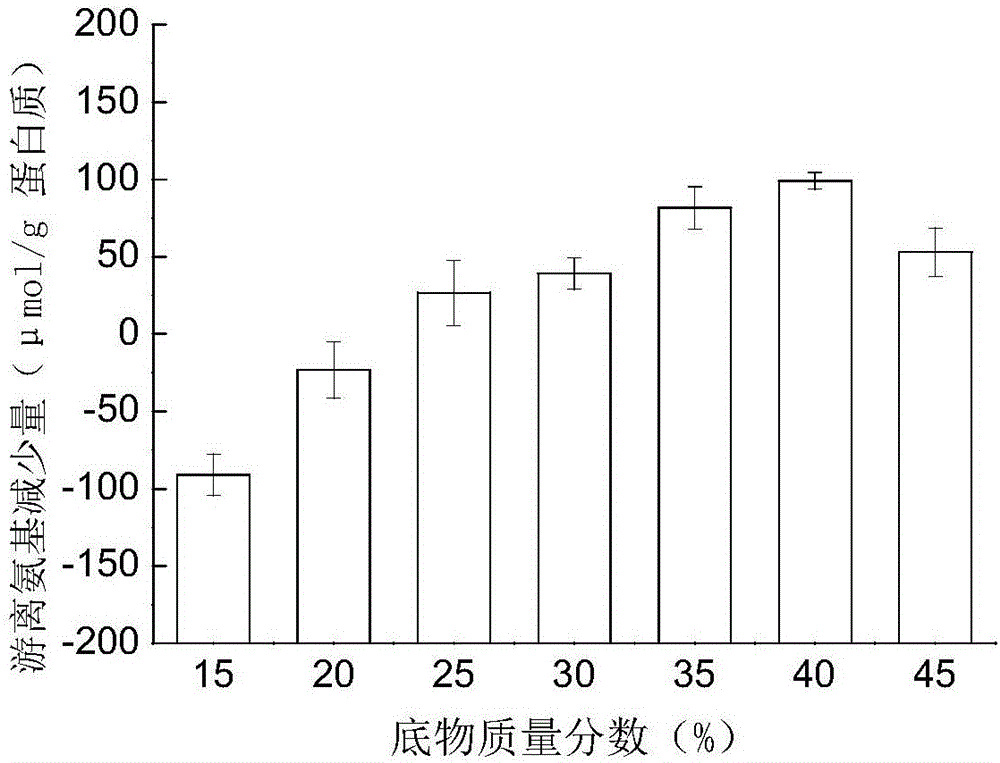

[0058] Example 3: Effects of different substrate mass fractions on protein-like modification reactions

[0059] Take 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9 g of soybean protein hydrolyzate freeze-dried powder and whey protein hydrolyzate freeze-dried powder respectively, and mix the two correspondingly. Dissolve with pH 5.0, 50mmol / L phosphate buffer solution, and the mass fractions of the prepared solutions are 15%, 20%, 25%, 30%, 35%, 40%, 45%, respectively. Add pepsin 2.0KU / g at the same time 蛋白 , and mix until the total volume is 4.0 mL. After reacting at 37°C for 3.0h, inactivate the enzyme with boiling water for 10min and cool to room temperature, dilute 10 times with water and measure the reduction of free amino acid.

[0060] Such as image 3 As shown, when the substrate mass fraction is 35%-40%, the reduction of free amino acids is large, indicating that the aggregation of peptides in the system is greater than the enzymatic hydrolysis. Therefore, the mass fraction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com