Temperature regulating system and method for increasing inlet flue gas temperature of SCR denitrification device

A temperature regulation system and inlet technology, applied in the field of temperature regulation system, can solve the problems of denitration, side reactions, failure, etc., and achieve the effects of easy transformation and operation, reduction of emissions, and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

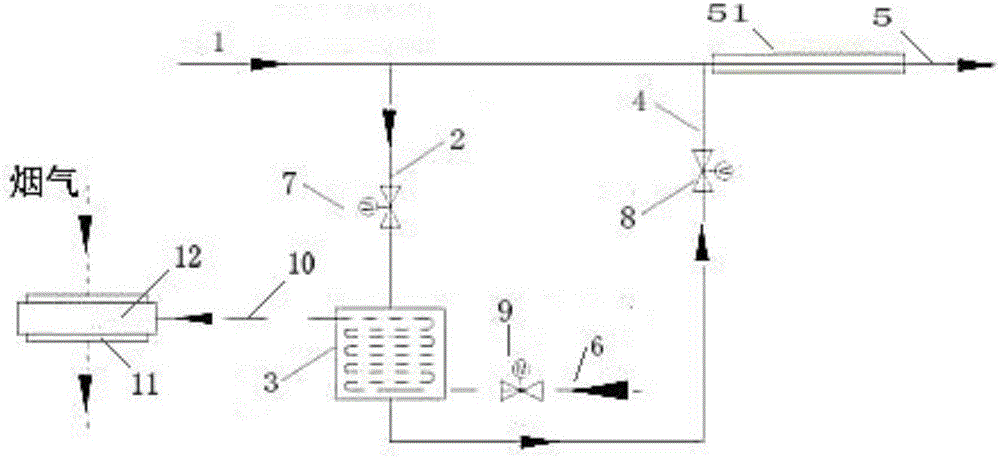

[0028] figure 1 It is a structural schematic diagram of a temperature regulation system disclosed in this embodiment, such as figure 1 As shown, the temperature adjustment system includes: reheat steam pipe (1), steam inlet pipe (2), heat exchanger (3), return steam pipe (4), reheat accident water spray pipe (5), reheat Thermal accident spray desuperheater (51) and water inlet pipe (6). Wherein, the inlet of the steam inlet pipe (2) communicates with the reheat steam pipe (1); the outlet of the steam inlet pipe (2) communicates with one side of the heat exchanger (3); the The inlet of the steam return pipe (4) is arranged on the side of the heat exchanger (3) away from the steam inlet pipe (2), and the steam return pipe (4) communicates with the heat exchanger (3); The reheat accident water spray pipe (5) is socketed with the reheat accident water spray desuperheater (51), and the reheat accident water spray pipe (5) communicates with the reheat steam pipe (1) and the The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com