Modified polybutylene succinate nanocomposite material and preparation method thereof

A technology of polybutylene succinate and nanocomposite materials, which is applied to the improvement of polybutylene succinate by octaphenyloctasilsesquioxane, and modified polybutylene succinate nanocomposites And its preparation field can solve problems such as insufficient rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Wherein, the nanocomposite material is obtained by the following preparation methods, including:

[0029] Step 1: Dry polybutylene succinate for 3-5 hours at 50-80°C;

[0030] Step 2: Mix polybutylene succinate and octaphenyl octasilsesquioxane for 3-5 minutes, then add modified loofah fiber, plasticizer, flame retardant and heat stabilizer, and continue mixing for 5~ 10min;

[0031] Step 3: granulation and injection molding to obtain the nanocomposite material.

[0032] Wherein, the preparation method of the modified loofah fiber comprises: crushing the loofah fiber into small pieces, and grinding into powder, passing through a 50-100 mesh sieve, and then drying in a vacuum environment at 70-100°C, and then mixing it with 40- 80ml of absolute ethanol was mixed, and ultrasonically dispersed for 5-20min to obtain a uniformly dispersed suspension; the coupling agent was dissolved in 40-80ml of absolute ethanol at a mass fraction of 0.5-1% to obtain a coupling agent solu...

Embodiment 1

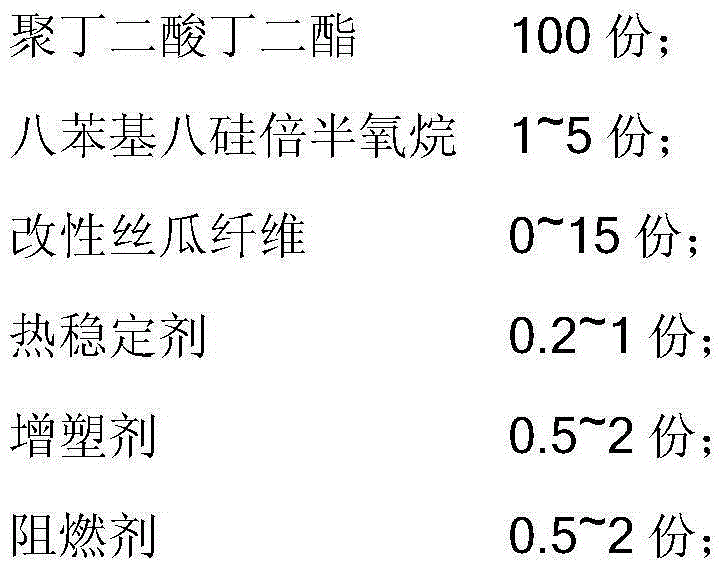

[0047] A modified polybutylene succinate nanocomposite material, its components and weight proportions include:

[0048]

[0049] Wherein, the nanocomposite material is obtained by the following preparation methods, including:

[0050] Step 1: Dry polybutylene succinate for 3-5 hours at 60°C;

[0051] Step 2: Put the loofah fiber in a pulverizer and crush it into small pieces, and grind it into powder with a ball mill, pass through a 50-100 mesh sieve, then dry it in a vacuum oven at 80°C, and then mix it with 50ml of absolute ethanol, and ultrasonically disperse for 10 minutes to obtain a uniformly dispersed suspension; dissolve the coupling agent KH550 in 50ml of absolute ethanol at a mass fraction of 0.5-1% to obtain a coupling agent solution; then mix the suspension and the coupling agent solution uniformly and place in Reflux at 80°C for 3-5h, cool to room temperature, centrifuge and dry in a vacuum oven at 80°C to obtain the modified loofah fiber;

[0052] Step 3: Usi...

Embodiment 2

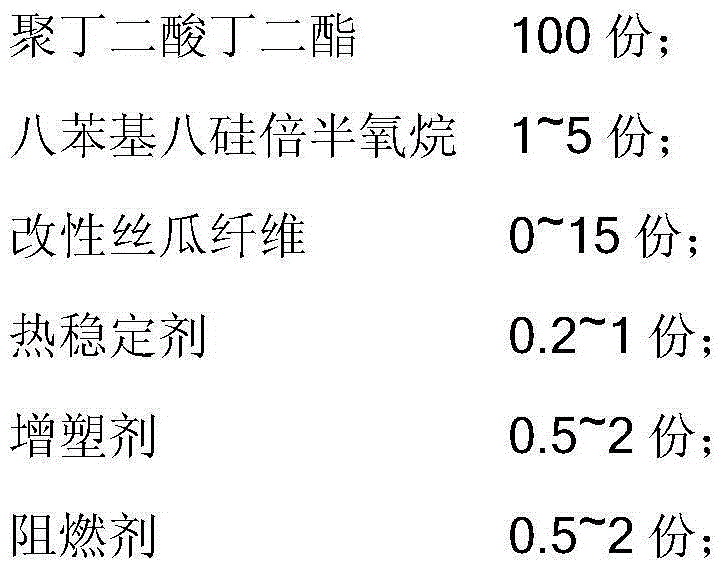

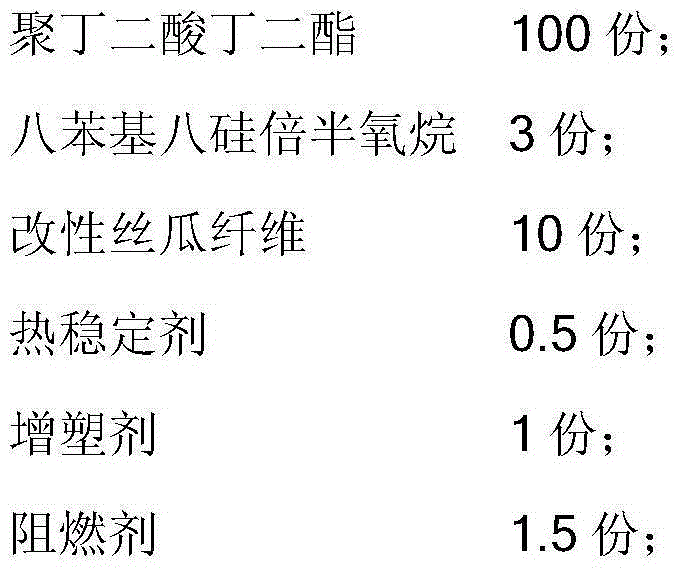

[0055] A modified polybutylene succinate nanocomposite material, its components and weight proportions include:

[0056]

[0057] Wherein, the nanocomposite material is obtained by the following preparation methods, including:

[0058] Step 1: Dry polybutylene succinate for 3-5 hours at 60°C;

[0059] Step 2: Put the loofah fiber in a pulverizer and crush it into small pieces, and grind it into powder with a ball mill, pass through a 50-100 mesh sieve, then dry it in a vacuum oven at 80°C, and then mix it with 50ml of absolute ethanol, and ultrasonically disperse for 10 minutes to obtain a uniformly dispersed suspension; dissolve the coupling agent KH560 in 50ml of absolute ethanol at a mass fraction of 0.5-1% to obtain a coupling agent solution; then mix the suspension and the coupling agent solution uniformly and place in Reflux at 80°C for 3-5h, cool to room temperature, centrifuge and dry in a vacuum oven at 80°C to obtain the modified loofah fiber;

[0060] Step 3: U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com