Apparatus for detecting component and detection method of apparatus for detecting component

A component and detection unit technology, which is applied to the equipment used to detect components and its detection field, can solve the problems of inability to meet the requirements of high-precision component detection and flexible production, flexible ability, and few detection items. Achieve the effects of shortening working hours, improving flexibility and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

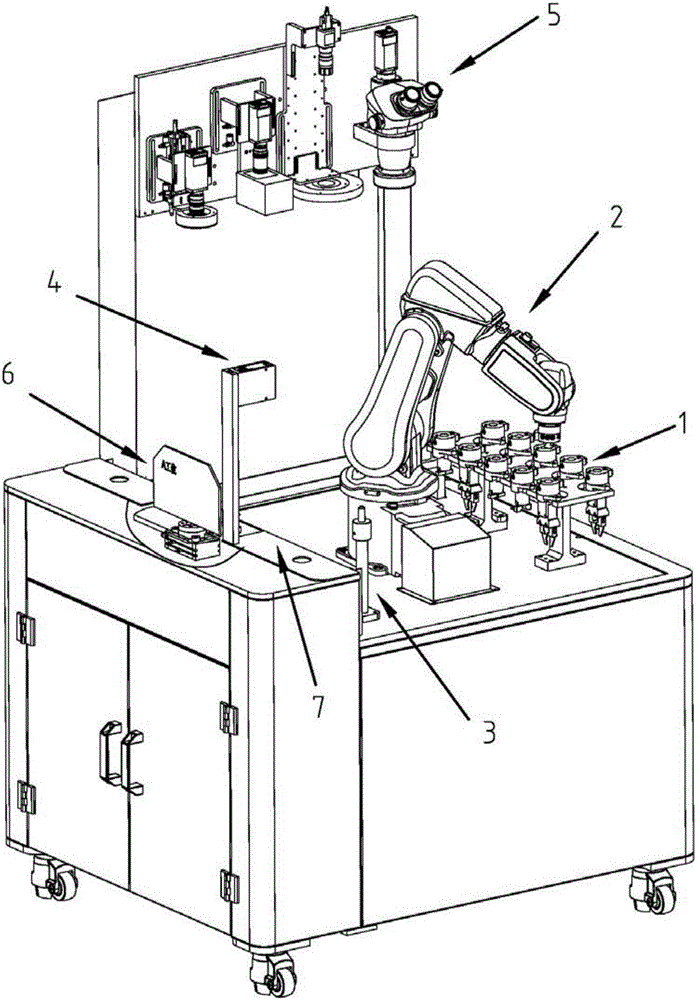

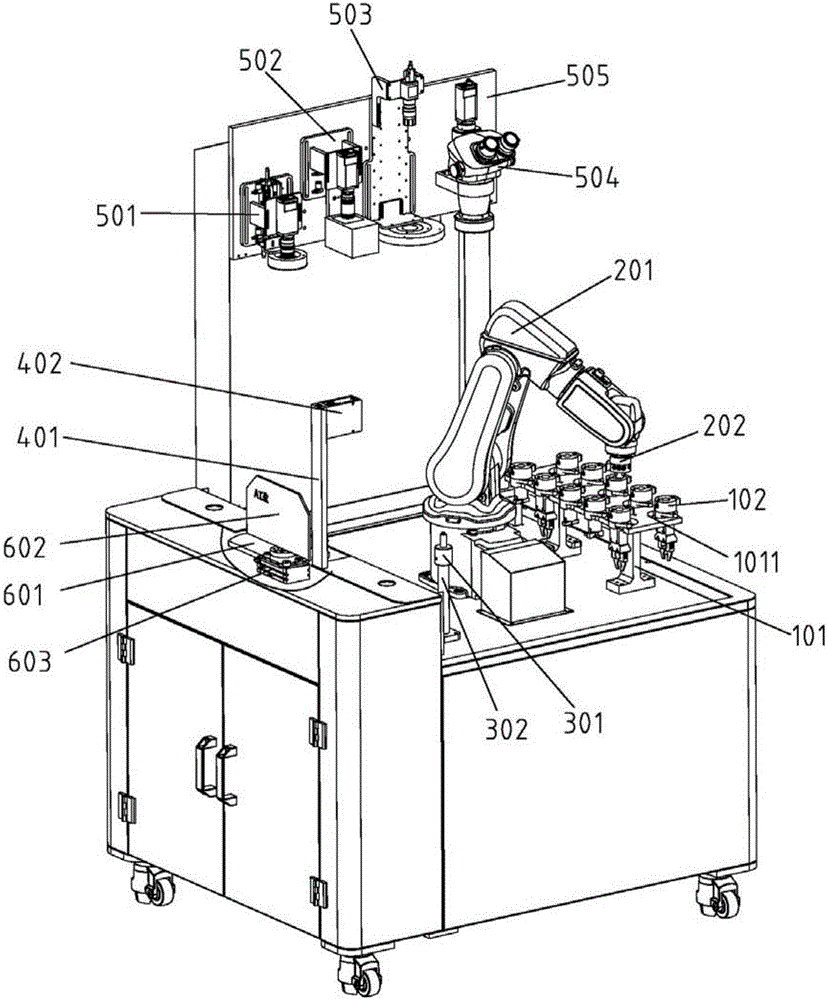

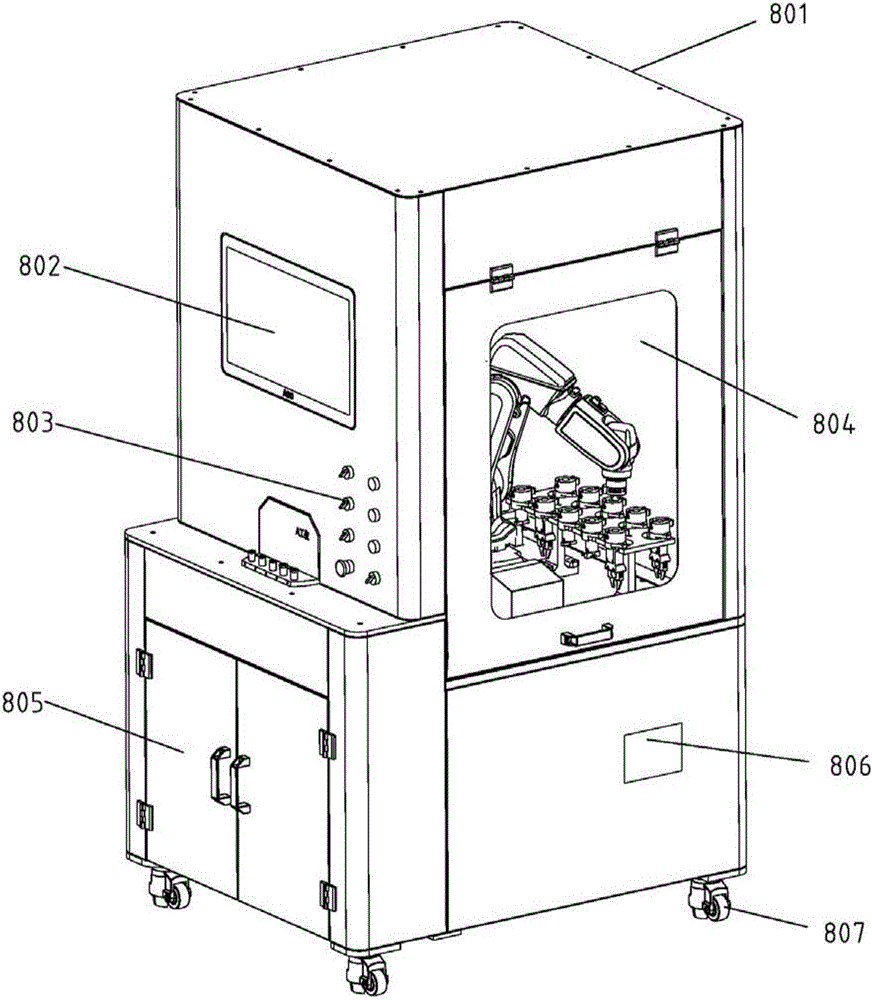

[0085] According to an embodiment of the present invention, the manipulator 201 first selects the end surface tooling 1023 when inspecting the components 901 . The manipulator 201 transports the component 901 from the detection station to the bottom of the first camera lens 501 in the detection unit 5 through the end surface tooling 1023, and the first camera lens 501 collects the components 901 such as inner diameter, slot width, slot center angle, etc. The computer system 802 of the equipment performs calculation and analysis to determine the detection information. After the inspection is completed, the manipulator 201 transports the components 901 to the transfer table 301 for temporary storage, and the manipulator 201 replaces the inner diameter tooling 1022 . The manipulator 201 transports the component 901 from the transfer table 301 to the bottom of the first camera lens 501 through the inner diameter tooling 1022, and collects the data of detection elements such as thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com