Electric axle driving system and automobile

A drive system, electric vehicle technology, applied to vehicle components, control devices, transportation and packaging, etc., can solve the problems of compression and deceleration mechanism available space, volume increase, electric drive system volume increase, etc., to achieve the goal of increasing the transmission ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

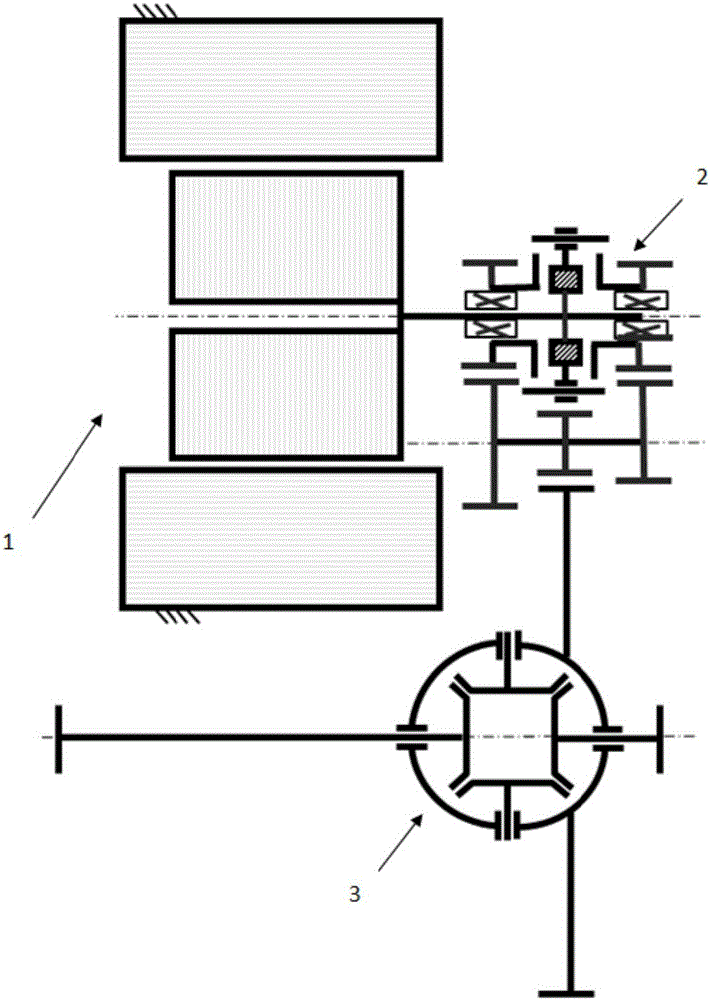

Image

Examples

Embodiment Construction

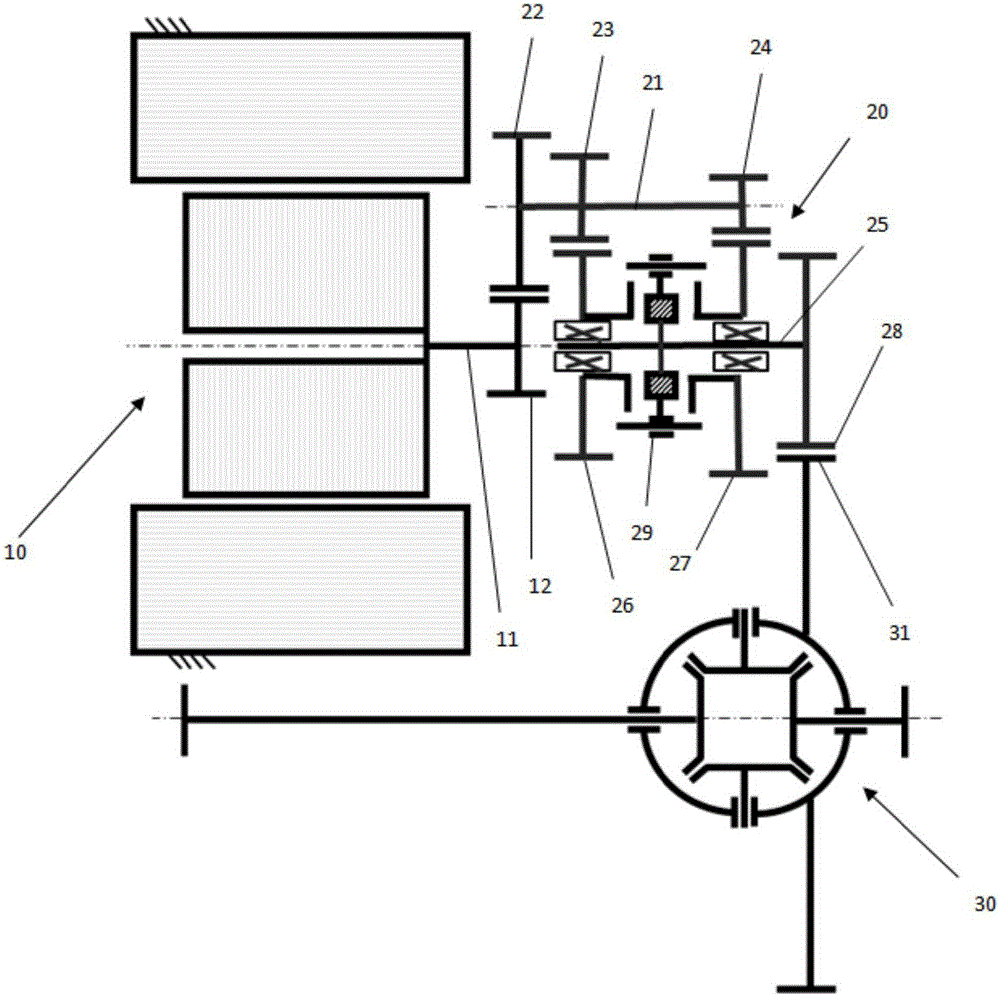

[0014] Such as figure 2 As shown, the electric shaft drive system of the first embodiment of the present invention includes a motor 10 , a reduction mechanism 20 and a differential 30 . Wherein the motor 10 has a stator located radially outside and a rotor located radially inside the stator, the rotor is fixedly connected with a motor output shaft 11 , and the motor output shaft 11 has a first fixed meshing gear 12 connected against torsion.

[0015] The reduction mechanism 20 includes an input shaft 21 and an output shaft 25 arranged in parallel. The second fixed meshing gear 22, the first II-speed gear 23 and the first I-speed gear 24 are arranged on the input shaft 21 in order to prevent rotation, and the second fixed meshing gear 22 is meshed with the first fixed meshing gear 12 on the output shaft of the motor to form a fixed meshing gear set to receive the power output from the output shaft 11 of the motor. The second II gear 26, the second I gear 27, and the first red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com