A method for film-swelling of linear hydrogenated styrene-based thermoplastic elastomers with low film-swelling rate

A thermoplastic elastomer and hydrogenated styrene technology, applied in the field of preparation of in-line hydrogenated styrene thermoplastic elastomers, can solve the problems of improving melt stability without mentioning, low dosage, difficult industrial production, and no control of die swell and other problems, to achieve the effect of easy industrial production, realization of industrial production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

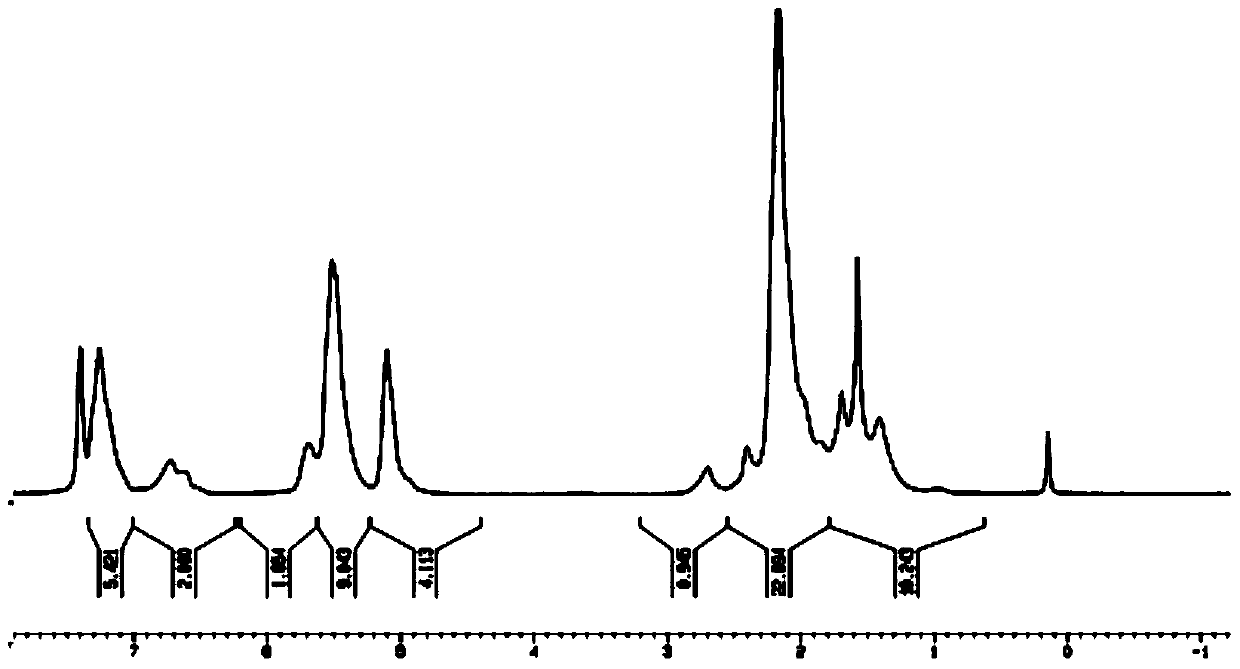

Image

Examples

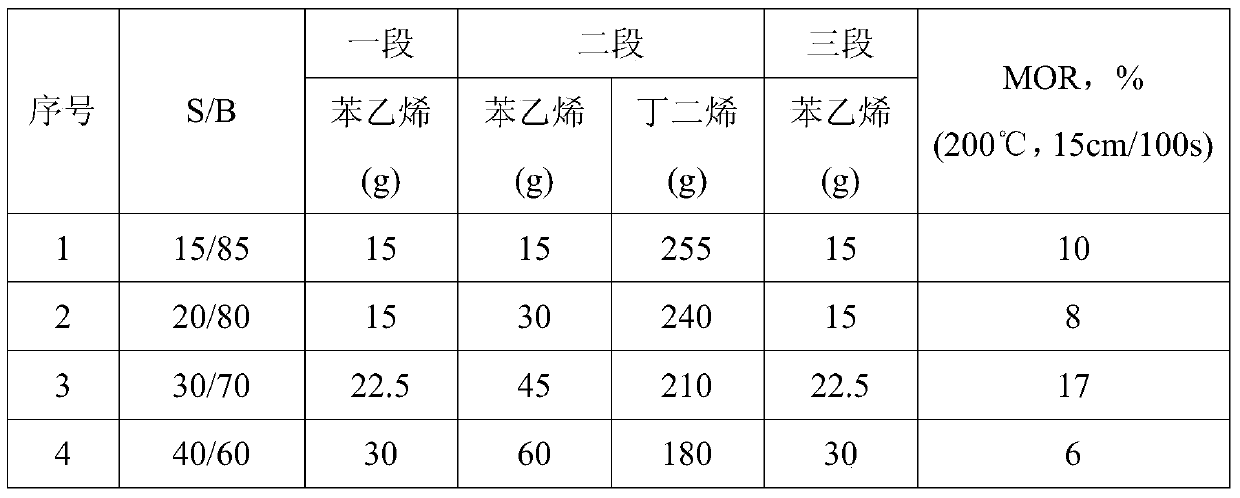

Embodiment 1

[0034] In a 5-liter polymerization kettle (with stirring) that has been cleaned and replaced with high-purity nitrogen, add metered cyclohexane (water value <20ppm), styrene, and regulator, heat the kettle to 45-55°C, and add Initiator n-butyllithium (or sec-butyllithium), react for 30 minutes, add the measured styrene and butadiene into the reactor at the same time, control the maximum temperature not to exceed 100 ° C, react for 30 minutes, finally add styrene, react 30min. After the polymerization reaction is completed, the glue solution is introduced into a 5-liter hydrogenation tank, the temperature is raised to 70°C, a hydrogenation catalyst is added, the hydrogenation pressure is 0.8-1.5Mpa, and the hydrogenation reaction lasts for 120 minutes. After the hydrogenation reaction is completed, the reaction is terminated, the glue solution is purified, the material is discharged, an antioxidant is added, the glue solution is condensed to obtain a white polymer, and the prod...

Embodiment 2

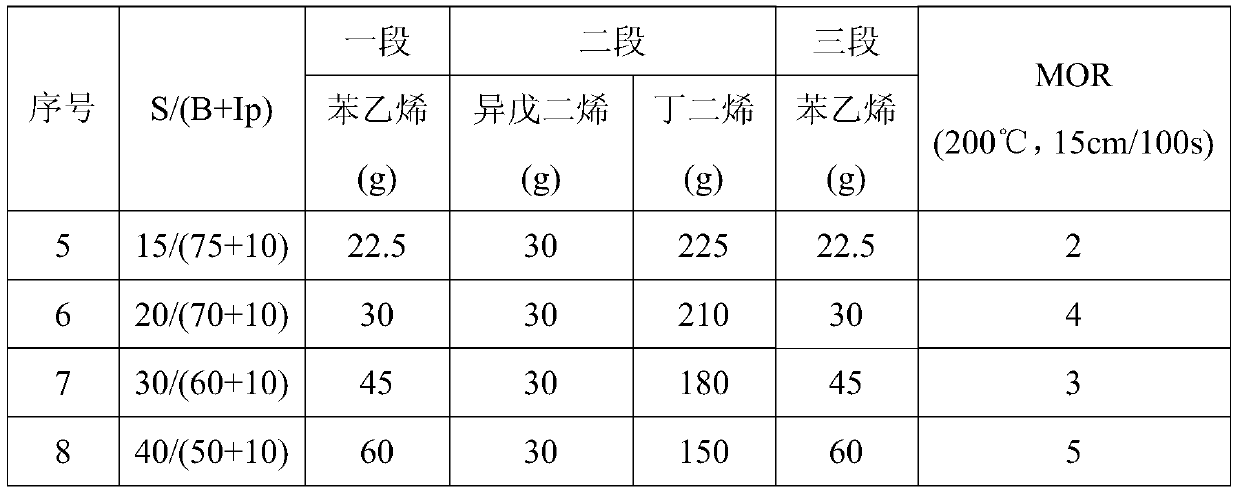

[0038] Test was carried out with isoprene instead of two-stage styrene, the reaction conditions were the same as in Example 1, and the experimental data are listed in Table 2.

[0039] Table 2

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com