Pump drive type two-phase fluid heat transport system

A heat transfer and fluid technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of insufficient driving force, small cooling capacity, large air duct pipeline size, etc., and achieve the elimination of relative height restrictions, installation Ease of maintenance and reduced pipe diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is carried out on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

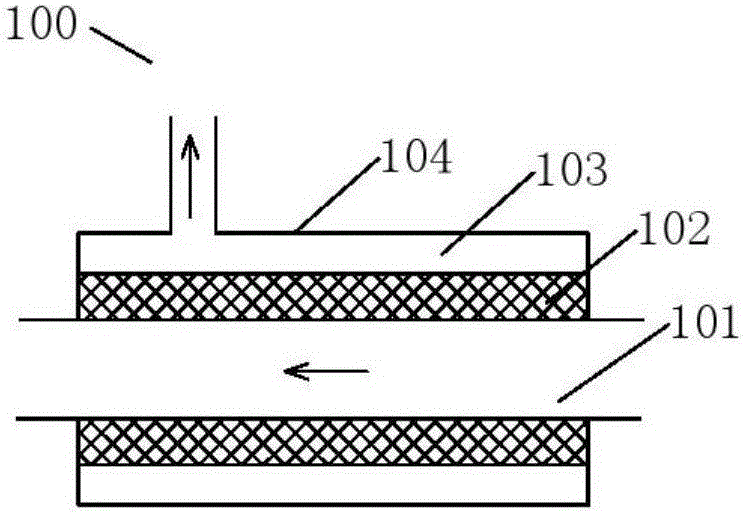

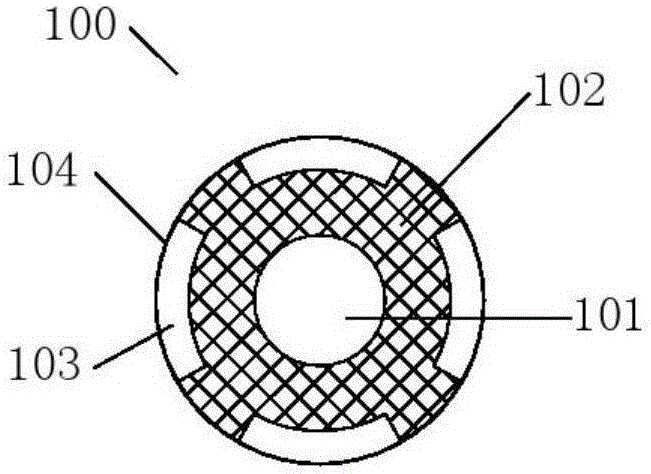

[0045] Single evaporator embodiment: figure 1 It is a longitudinal sectional view of a single evaporator embodiment in the present invention, figure 2 It is a cross-sectional view of a single evaporator embodiment of the present invention. Such as figure 1 and figure 2 As shown, the evaporator 100 includes a liquid channel 101 , a capillary wick 102 , a gas channel 103 and a housing 104 . The capillary wick 102 isolates the liquid channel 101 and the gas channel 103 of the evaporator 100 from each other. The capillary core 102 is a porous sintered structure, and its pore size can be an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com