Method for detecting cold brittleness transition temperature of metal material

A metal material, transition temperature technology, applied in the direction of analyzing materials, using sonic/ultrasonic/infrasonic waves for material analysis, measuring devices, etc. To achieve the effect of high test efficiency, accurate and reliable data, and high academic research value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

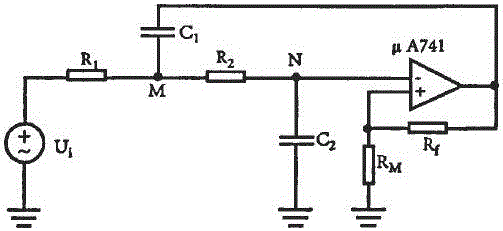

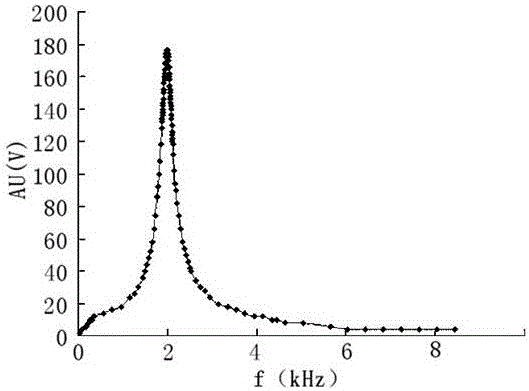

[0033] In this embodiment, normalized No. 45 ordinary carbon steel sample is selected and processed into a cylindrical sample of 8 mm × 120 mm; the Agilent 33220A frequency synthesizer is used as the signal source, and the Tektronix TDS-2002B oscilloscope observes the signal, and the signal is amplified and band-passed. filter, the schematic diagram is as figure 1 As shown, the amplitude-frequency characteristic curve of the band-pass filter at 2KHz frequency point is as follows figure 2 As shown, the exciter is an electromagnetic exciter with a working frequency range of 0.1~2KHz±3DB, and the vibrator is a tartaric acid crystal with a working frequency range of 0.5~3KHz±2DB.

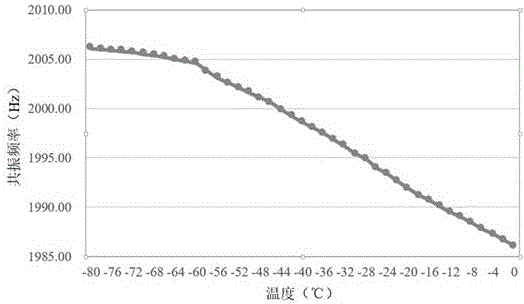

[0034] The specific implementation process of this embodiment: hang the two ends of the sample in the low-temperature container with cotton thread, the hanging position is near the node position of the sample, and the other section of the cotton thread is respectively the exciter and the vibration pick...

Embodiment 2

[0036] In this example, the annealed Q460 sample is selected and processed into a sample of 8 mm×10 mm×200 mm. The Agilent33220A frequency synthesizer is used as the signal source, and the Tektronix TDS-2002B oscilloscope observes the signal, and the signal is amplified and band-pass filtered. The schematic diagram is as follows figure 1 As shown, the amplitude-frequency characteristic curve of the band-pass filter at 2KHz frequency point is as follows figure 2 As shown, the exciter is an electromagnetic exciter with a working frequency range of 0.5~2KHz±4DB, and the vibrator is an electromagnetic vibrator with a working frequency range of 1~3KHz±3DB.

[0037] The specific implementation process of this embodiment: the sample, the exciter, and the vibration pick-up are placed in a low-temperature container, the contacts of the exciter and the vibration pick-up are placed horizontally upwards, the distance between the contacts is 120 mm, and the left and right sides of the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com