A cone-type drying device for nuclear power plant waste resin

A drying device and waste resin technology, applied in heating device, garbage drying, drying room/container, etc., can solve the problems of low efficiency and small amount of one-time treatment, so as to speed up evaporation rate, reduce flammability and explosion, and reduce evaporation The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

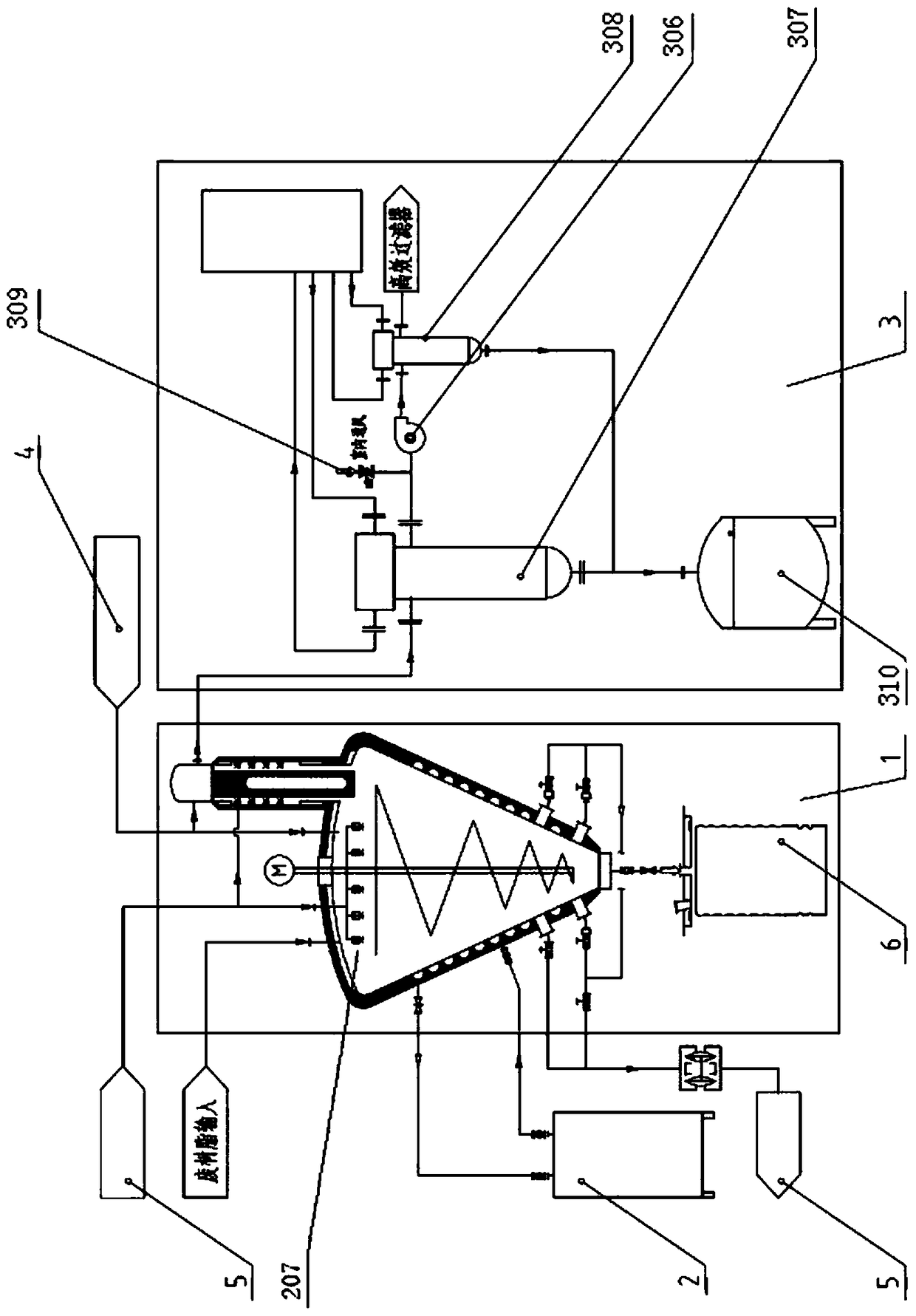

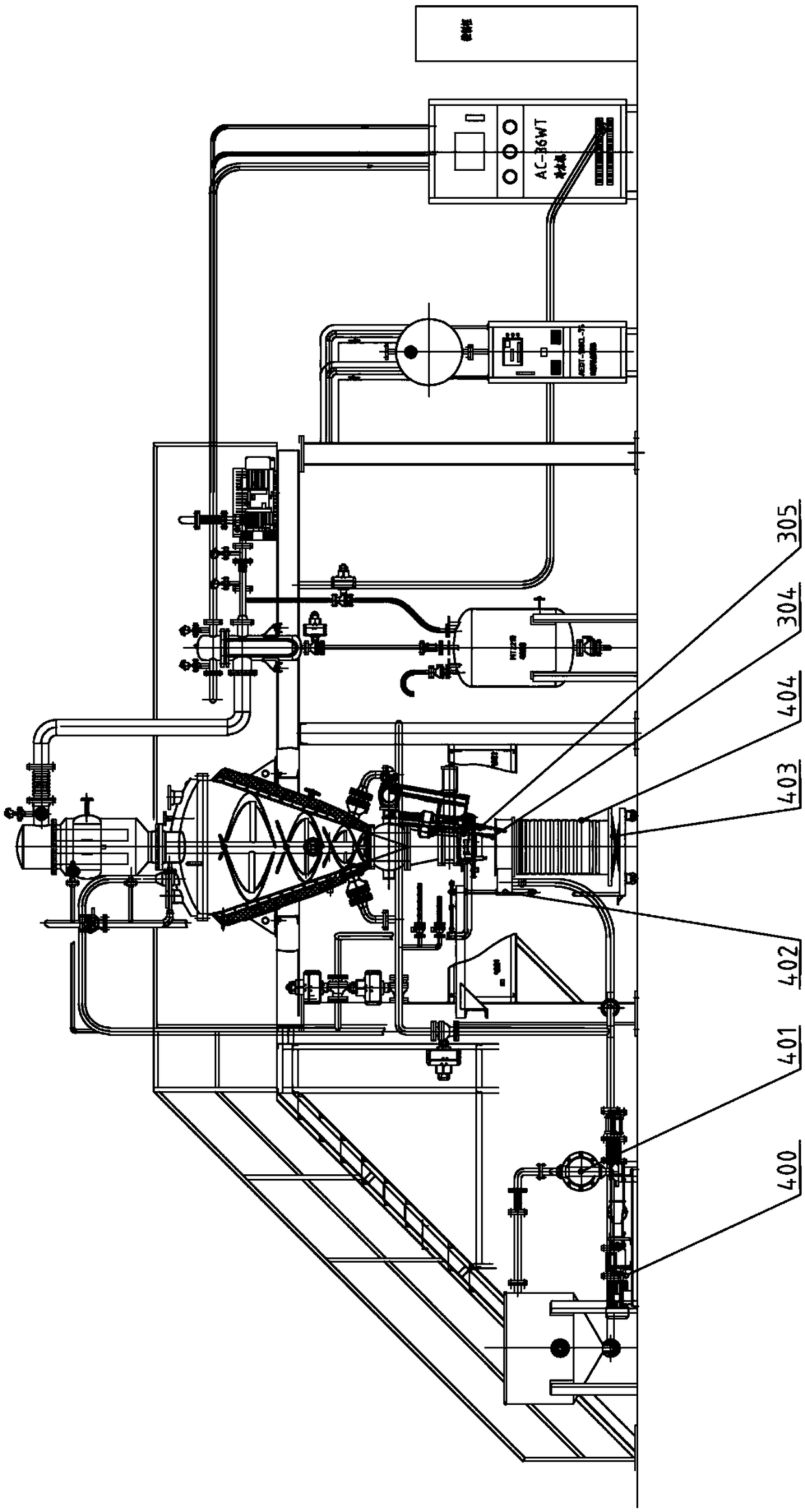

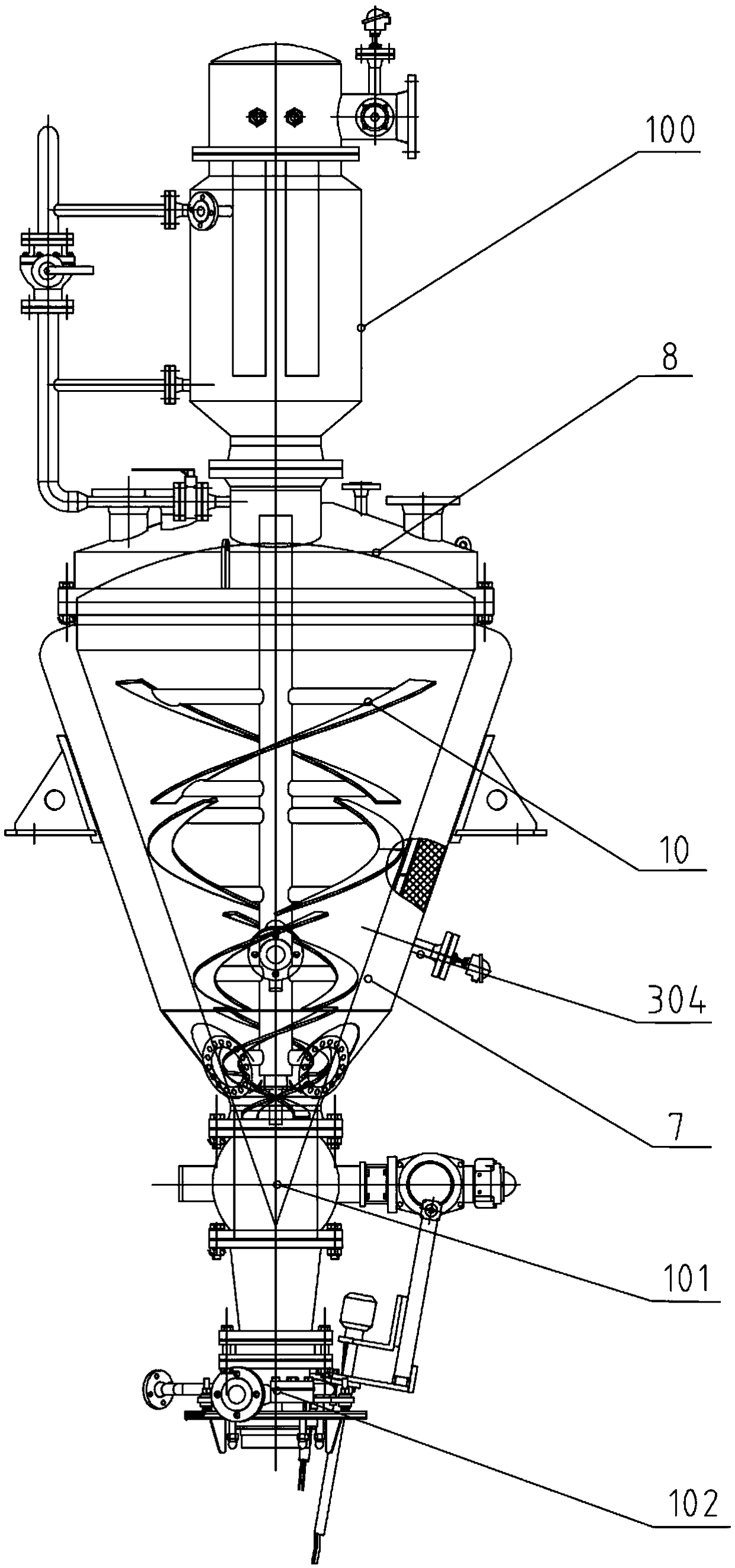

[0038] like Figure 1 to Figure 6 As shown, the present invention relates to a conical drying device for waste resin in a nuclear power plant, including a main device 1 of a conical dryer for vacuum drying of waste resin, a hot oil unit 2 for heating and cooling the conical dryer, and a device for maintaining The vacuum level in the main body of the dryer and the condensing system 3 for condensing the steam, the nitrogen purging system 4 for system protection and cleaning of the cleanable filter, the cleaning and dewatering system for dewatering the waste resin and cleaning the system pipeline 5. The resin barreling system 6 for simulating the SRTF station of the nuclear island; the vacuum pump 306, the primary condenser 307, the secondary condenser 308, the pneumatic regulating valve 309, and the vacuum pump 306 are connected to the air extraction and condensation system 3 of the present invention. Condensate tank 310;

[0039] The nitrogen purging system 4 is connected in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com