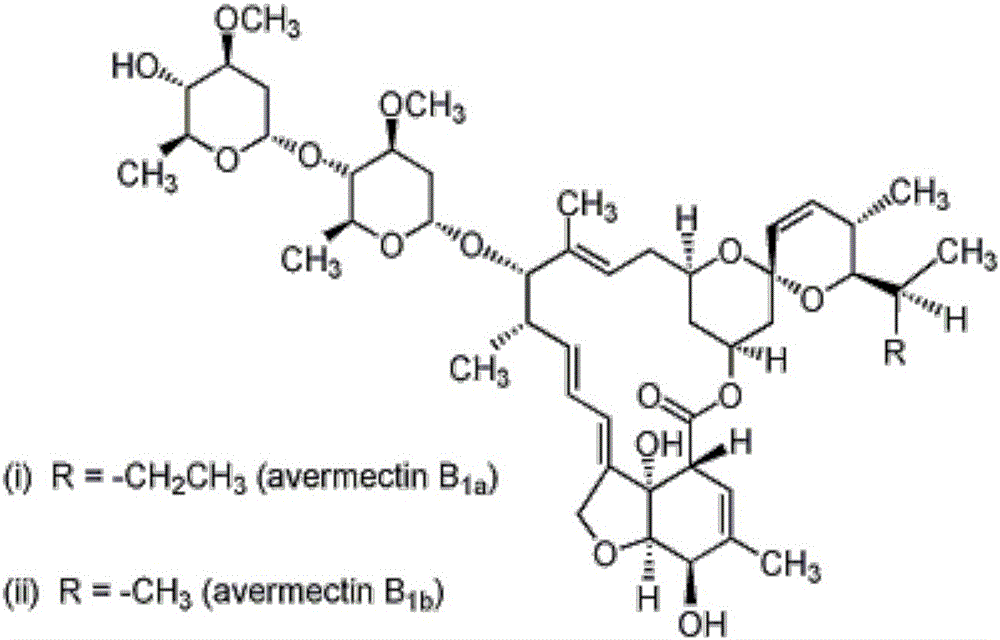

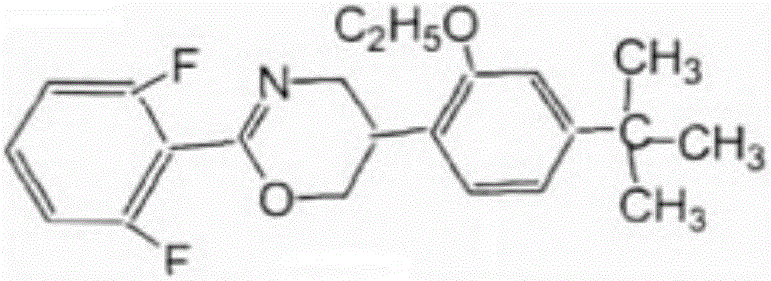

Micro-capsule suspension-suspending agent containing abamectin and etoxazole and preparation method of micro-capsule suspension-suspending agent

A technology of abamectin and microcapsule suspension, applied in the field of pesticides, can solve the problems of low storage stability of chemicals, insufficient synergistic effect, uneven spraying of chemicals, etc., and achieve the goals of reducing dosage, reducing pollution and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

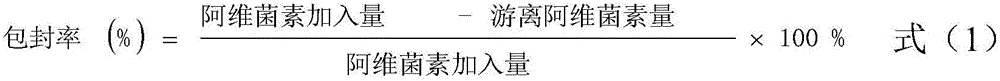

[0011] The present disclosure provides a method for preparing a microcapsule suspension-suspending agent containing abamectin and etoxazole. The preparation method may include the following steps: (1) mixing the first solution and the second solution uniformly to obtain the first Materials; wherein the first solution contains benzoyl peroxide and methyl methacrylate; the second solution contains abamectin EC; the weight ratio of the first solution to the second solution is 1: (5-10); (2) Mix the first material and water uniformly, and stir to obtain the second material; the weight ratio of the first material to water is 1: (1-5); (3) Add NaHSO to the second material 3 Solution, mixed uniformly to obtain the third material; the second material contains benzoyl peroxide and NaHSO 3 NaHSO in solution 3 The weight ratio is 1: (1-3); (4) The third material is cured and polycondensed to obtain a cured polycondensation product; a pH regulator is added to the cured polycondensation prod...

Embodiment 1

[0039] Benzoyl peroxide (BPO) is dissolved in methyl methacrylate (MMA) and mixed uniformly, wherein the weight ratio of BPO to MMA is 1:1000.

[0040] Abamectin, N-methylpyrrolidone, calcium dodecyl benzene sulfonate, and sorbitan monostearate polyoxyethylene ether are mixed uniformly to obtain abamectin EC, wherein the avermectin The mass ratio of mycin to N-methylpyrrolidone, calcium dodecylbenzenesulfonate, and sorbitan monostearate polyoxyethylene ether is 1:8.5:1:1.5:0.4.

[0041] The obtained BPO / MMA solution and abamectin EC are mixed uniformly to obtain the first material, wherein the weight ratio of the BPO / MMA solution and abamectin EC is 1:100; at room temperature, the first material A material is mixed with water, and stirred at 50r / min for 3min to obtain the second material, wherein the weight ratio of the first material to water is 1:1; at room temperature, 0.01% by weight of NaHSO 3 The solution was slowly added dropwise to the second material at a rate of 1 drop ev...

Embodiment 2

[0045] Benzoyl peroxide (BPO) was dissolved in methyl methacrylate (MMA) and mixed uniformly. The weight ratio of BPO to MMA was 1:1000.

[0046] The preparation method of abamectin EC is the same as in Example 1.

[0047] The obtained BPO / MMA solution and abamectin EC are mixed uniformly to obtain the first material, wherein the weight ratio of the BPO / MMA solution and abamectin EC is 1:200; at room temperature, the first material A material is mixed with water, and stirred at 100r / min for 3min to obtain the second material; the weight ratio of the first material to water is 1:0.8; at room temperature, 0.01% by weight of NaHSO 3 The solution was slowly added dropwise to the second material at a rate of 1 drop every 4-5 minutes, while stirring it at a rate of 100r / min to obtain a third material, wherein the BPO in the second material With NaHSO 3 NaHSO in solution 3 The weight ratio is 1:1.5; at room temperature, the third material is cured and polycondensed for 2 hours to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com