Chewing gum containing gelatin-octenyl succinic anhydride modified starch-L-menthol microcapsules and preparation method thereof

A technology of octenyl succinic acid and starch ester, which is applied in the field of chewing gum to achieve the effects of low production cost, prolonged oral cavity residence time and good release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

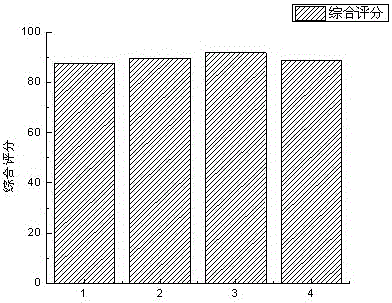

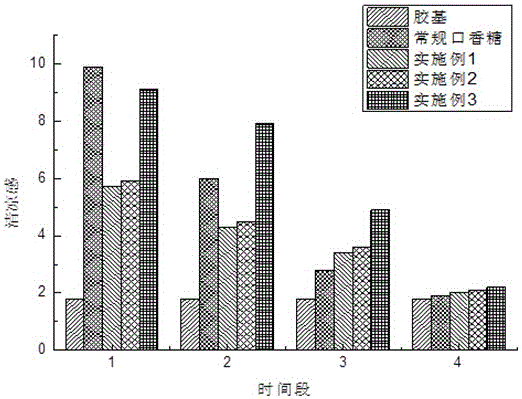

Examples

Embodiment 1

[0026] A preparation method for chewing gum containing gelatin-octenyl starch succinate-L-menthol microcapsules, comprising the following steps:

[0027] (1) Put 20 parts of polyvinyl acetate in a constant temperature incubator to maintain a humidity of 40% rh, and control the temperature to 50° C. to soften for 3 hours for later use.

[0028] (2) The weight ratio of fructose syrup is 15 parts, the weight ratio of sorbitol is 60 parts, and the weight ratio of glycerin is 2 parts, which are respectively added in the polyvinyl acetate softened in the step (1) as auxiliary materials, polyacetic acid The weight ratio of vinyl ester is 20 parts, heat preservation under the condition of 50-60°C, the auxiliary materials and polyvinyl acetate are mixed and stirred first during operation, and the weight ratio of gelatin-octenyl succinic acid starch-L-menthol microcapsules is 3 Parts, added as essence, heat the blended and mixed polyvinyl acetate ingredients to 80-90°C, condense and coo...

Embodiment 2

[0035] (1) Put 20 parts of gum base in a constant temperature incubator to maintain a humidity of 50% rh, control the temperature at 60° C. and soften for 4 hours for later use.

[0036] (2) The weight ratio of fructose syrup is 20 parts, the weight ratio of sorbitol is 55 parts, and the weight ratio of glycerin is 1 part, which are respectively added to the softened polyvinyl acetate in step (1) as auxiliary materials, polyacetic acid The weight ratio of vinyl ester is 20 parts, keep warm at 50-60°C, the auxiliary materials and polyvinyl acetate are mixed and stirred first during operation, the weight ratio of gelatin-octenyl succinic acid starch ester-L-menthol microcapsules It is 4 parts, added as essence, heat the blended and mixed polyvinyl acetate ingredients to 80-90°C, condense and cool, put the polyvinyl acetate containing auxiliary materials into an extruder and squeeze out The strip-shaped sugar base with tight structure and smooth surface is repeatedly extruded thr...

Embodiment 3

[0039] (1) Put 20 parts of polyvinyl acetate in a constant temperature incubator to maintain a humidity of 60% rh, control the temperature at 70° C. and soften for 5 hours for later use.

[0040] (2) The weight ratio of fructose syrup is 22 parts, the weight ratio of sorbitol is 50 parts, and the weight ratio of glycerin is 3 parts, which are respectively added to the softened gum base in step (1) as auxiliary materials, polyvinyl acetate The weight ratio of 20 parts, heat preservation under the condition of 50 ~ 60 ℃, the auxiliary materials and polyvinyl acetate are mixed and stirred first during operation, and the weight ratio of gelatin-octenyl succinic acid starch ester-L-menthol microcapsules is 5 Parts, added as essence, heat the blended and mixed polyvinyl acetate ingredients to 80-90°C, condense and cool, put the polyvinyl acetate containing auxiliary materials into an extruder and extrude, and the extruded tissue is tight , strip-shaped sugar base with a smooth surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com