A kind of regeneration method of zinc oxide desulfurization waste agent

A zinc oxide and waste agent technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as low regeneration rate of zinc oxide desulfurization waste agent, reduced activity of regenerated desulfurizer, volatilization of elemental zinc, etc., to achieve The effect of avoiding the loss of zinc ions, improving the regeneration rate, and avoiding the loss of zinc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

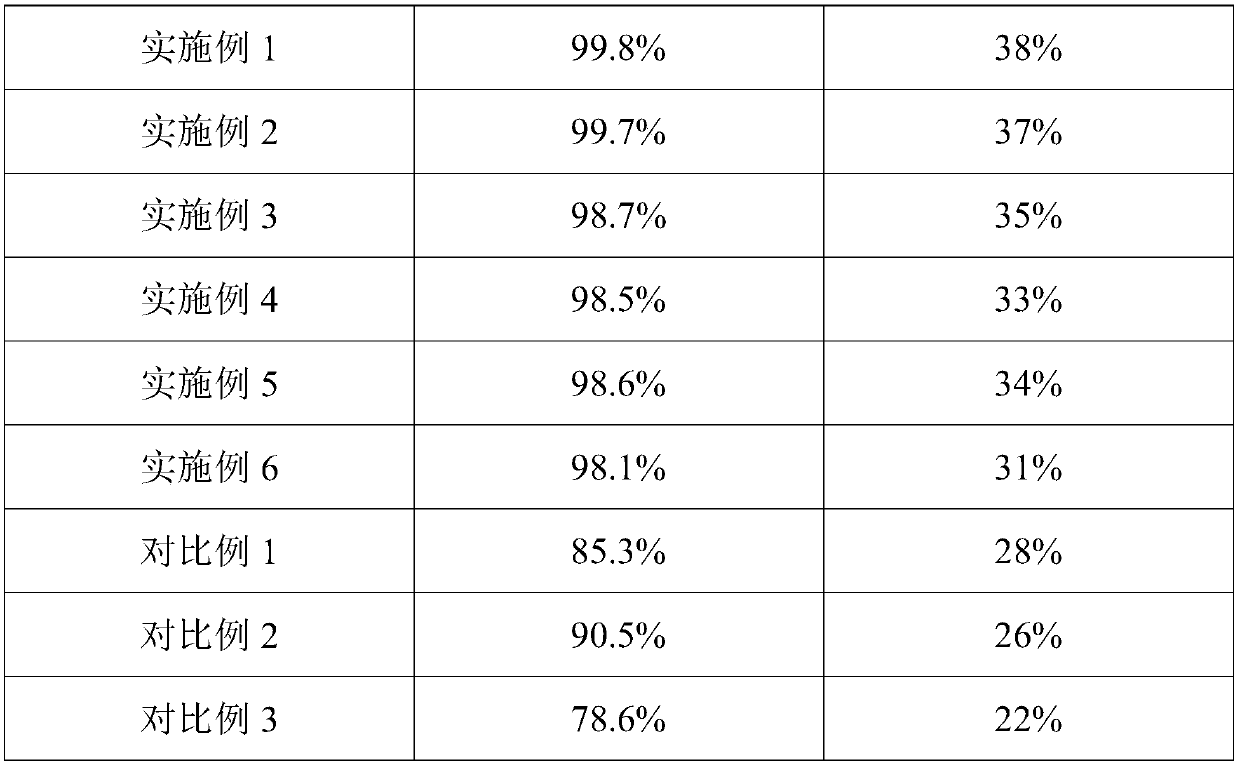

Examples

Embodiment 1

[0043] The present embodiment provides a kind of regeneration method of zinc oxide desulfurization waste agent, comprises the following steps:

[0044] (1) Grinding the waste zinc oxide desulfurization agent at a temperature of 40°C to 200 meshes, and drying the crushed zinc oxide desulfurization waste agent to control its moisture content at 6wt%;

[0045] (2) Aerobically roasting the waste zinc oxide desulfurization agent at 750° C. for 5 hours to obtain inactive zinc oxide materials and waste gas;

[0046] (3) Recover the heat in the waste gas, and collect the dust in the waste gas, and then use 25wt% and 5wt% sulfuric acid aqueous solution to contact the waste gas countercurrently, wash the waste gas, and collect the washing liquid;

[0047] (4) Add the washing liquid collected in the step (3) to the inactive zinc oxide material collected in the step (2) and the dust collected in the step (3), so that the zinc oxide and sulfuric acid Perform metathesis reaction at 30°C fo...

Embodiment 2

[0052] The present embodiment provides a kind of regeneration method of zinc oxide desulfurization waste agent, comprises the following steps:

[0053] (1) Grinding the waste zinc oxide desulfurization agent at a temperature of 30°C to 150 meshes, and drying the crushed zinc oxide desulfurization waste agent, controlling its moisture content at 8wt%;

[0054] (2) Roasting the zinc oxide desulfurization waste agent aerobically at 800°C for 3 hours, collecting inactive zinc oxide materials and waste gas;

[0055] (3) Recover the heat in the waste gas, and collect the dust in the waste gas, and then use 35wt% and 3wt% sulfuric acid aqueous solution to contact the waste gas countercurrently, wash the waste gas, and collect the washing liquid;

[0056] (4) Add the washing liquid collected in the step (3) to the inactive zinc oxide material collected in the step (2) and the dust collected in the step (3), so that the zinc oxide and sulfuric acid Perform metathesis reaction at 20°C ...

Embodiment 3

[0061] The present embodiment provides a kind of regeneration method of zinc oxide desulfurization waste agent, comprises the following steps:

[0062] (1) Grinding the waste zinc oxide desulfurization agent at a temperature of 40°C to 180 meshes, and drying the crushed zinc oxide desulfurization waste agent to control its moisture content at 7wt%;

[0063] (2) Roasting the waste zinc oxide desulfurization agent aerobically at 850°C for 2 hours, collecting inactive zinc oxide materials and waste gas;

[0064] (3) Recover the heat in the waste gas, and collect the dust in the waste gas, then use 30wt% and 4wt% sulfuric acid to contact the waste gas countercurrently, wash the waste gas, and collect the washing liquid;

[0065] (4) Add the washing liquid collected in the step (3) to the inactive zinc oxide material collected in the step (2) and the dust collected in the step (3), so that the zinc oxide and sulfuric acid Perform metathesis reaction at 30°C for 2 hours. During the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com