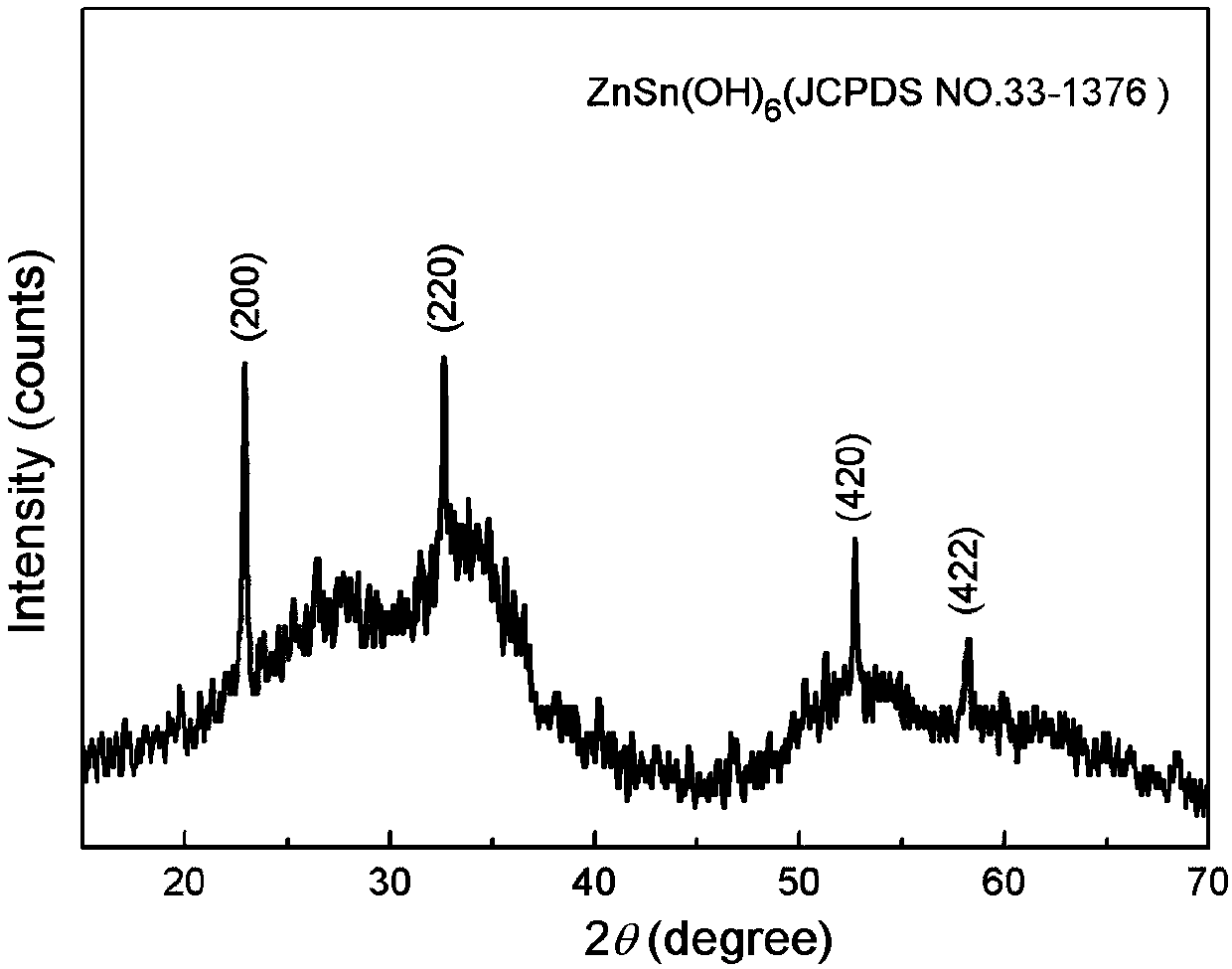

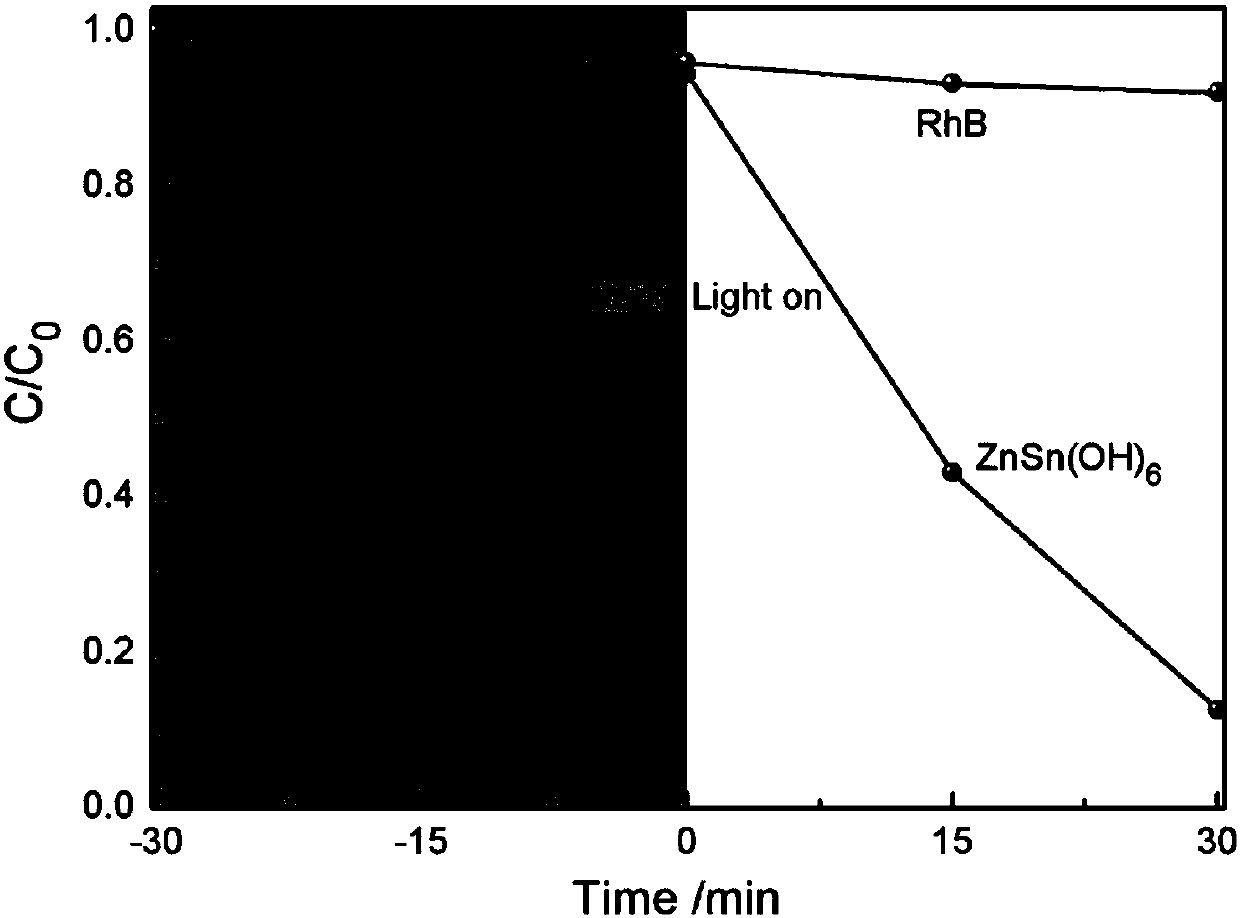

A kind of znsn(oh)6 powder and its preparation method and application

A technology of powder and reaction, which is applied in chemical instruments and methods, inorganic chemistry, water treatment of special compounds, etc., can solve the problems of no patents and literature reports, no reports, etc., achieve short reaction time, excellent photocatalytic performance, The effect of high photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Add Zn(NO 3 ) 2 ·6H 2 O is dissolved in ethylene glycol solution to give Zn(NO 3 ) 2 A Zn solution with a concentration of 0.002mol / L;

[0030] Step 2: Add SnCl 4 ·5H 2 O dissolved in deionized water to give SnCl 4 Sn solution with a concentration of 0.001mol / L;

[0031] Step 3: 20mL Zn solution and 20mL Sn solution were magnetically stirred until uniform to obtain a mixed solution, wherein the molar ratio of Zn to Sn was 2:1;

[0032] Step 4: Add 15 mL of hydrazine hydrate solution (concentration: 0.6 mol / L) to 40 mL of the mixed solution to adjust the pH value of the mixed solution to obtain a precursor solution;

[0033] Step 5: Add the precursor solution into the microwave hydrothermal reaction kettle, place the microwave hydrothermal reaction kettle in the microwave-assisted hydrothermal synthesizer, set the power to 300W, and conduct a microwave hydrothermal reaction at 180°C for 60 minutes;

[0034] Step 6: After the reaction is finished, wash th...

Embodiment 2

[0036] Step 1: Add Zn(NO 3 ) 2 ·6H 2 O is dissolved in ethylene glycol solution to give Zn(NO 3 ) 2 A Zn solution with a concentration of 0.001mol / L;

[0037] Step 2: Add SnCl 4 ·5H 2 O dissolved in deionized water to give SnCl 4 Sn solution with a concentration of 0.0005mol / L;

[0038] Step 3: Magnetically stir 15mL of Zn solution and 15mL of Sn solution until uniform to obtain a mixed solution, wherein the molar ratio of Zn to Sn is 2:1;

[0039] Step 4: Add 13 mL of hydrazine hydrate solution (concentration: 0.8 mol / L) to 30 mL of the mixed solution to adjust the pH value of the mixed solution to obtain a precursor solution;

[0040] Step 5: Add the precursor solution into the microwave hydrothermal reaction kettle, place the microwave hydrothermal reaction kettle in the microwave-assisted hydrothermal synthesizer, set the power to 280W, and conduct a microwave hydrothermal reaction at 170°C for 70 minutes;

[0041] Step 6: After the reaction is finished, wash the ...

Embodiment 3

[0043] Step 1: Add Zn(NO 3 ) 2 ·6H 2 O is dissolved in ethylene glycol solution to give Zn(NO 3 ) 2 A Zn solution with a concentration of 0.003mol / L;

[0044] Step 2: Add SnCl 4 ·5H 2 O dissolved in deionized water to give SnCl 4 Sn solution with a concentration of 0.0015mol / L;

[0045] Step 3: 25mL Zn solution and 25mL Sn solution were magnetically stirred until uniform to obtain a mixed solution, wherein the molar ratio of Zn to Sn was 2:1;

[0046]Step 4: Add 17 mL of hydrazine hydrate solution (concentration: 0.4 mol / L) to 50 mL of the mixed solution to adjust the pH value of the mixed solution to obtain a precursor solution;

[0047] Step 5: Add the precursor solution into the microwave hydrothermal reaction kettle, place the microwave hydrothermal reaction kettle in the microwave-assisted hydrothermal synthesizer, set the power to 290W, and conduct a microwave hydrothermal reaction at 190°C for 50 minutes;

[0048] Step 6: After the reaction is over, wash the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com