fe-tio 2 nanotube/g-c 3 no 4 Composite materials and their preparation methods and applications

A composite material, g-c3n4 technology, applied in the field of Fe-TiO2 nanotube/g-C3N4 composite material and its preparation, can solve the problems of difficult precise control of components and structure, further improvement of catalytic performance, complex composite process, etc. , to achieve the effect of improving photocatalytic efficiency, large specific surface area and high photocatalytic degradation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

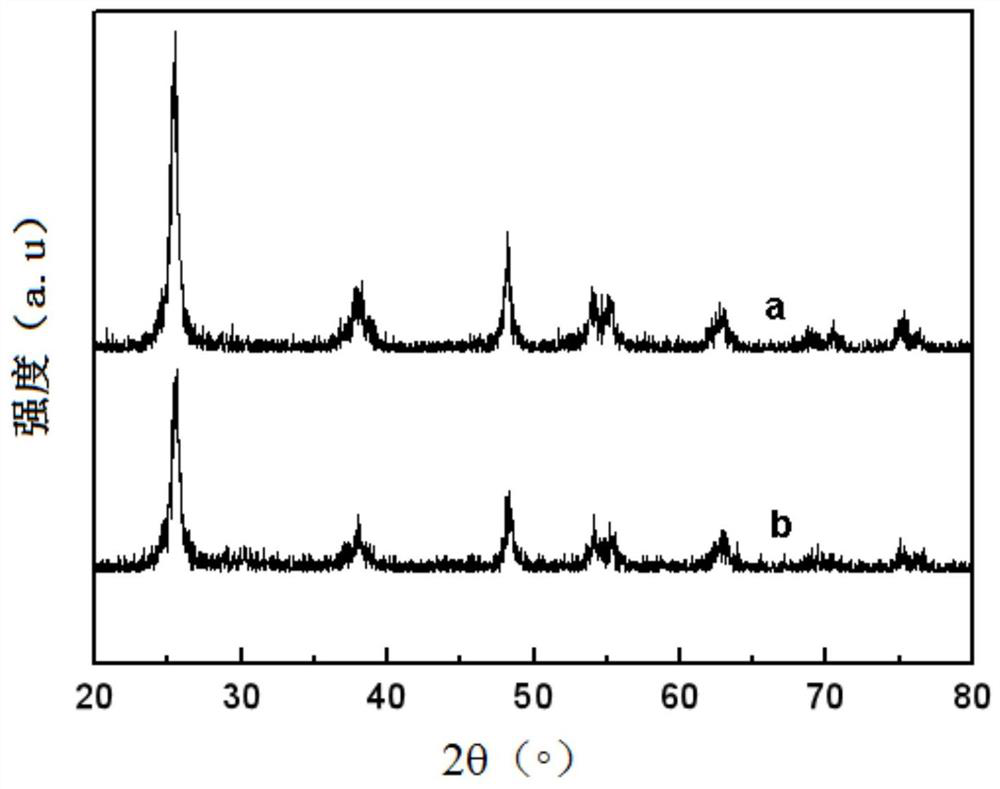

[0046] A Fe-TiO 2 Nanotube / g-C 3 N 4 Preparation method of composite material:

[0047] 1) Preparation of TiO 2 Nano powder

[0048] Weigh TiCl 4 Added to 4mol / L hydrochloric acid solution to make TiCl 4 Concentration of 0.5mol / L, ultrasound for 35min to obtain a light yellow sol, aging at room temperature for 12h, washing with water and ethanol respectively, drying at 80°C for 3h, and calcining at 450°C for 3h to obtain anatase-type sol with a particle size of about 30nm Nano-TiO 2 Powder.

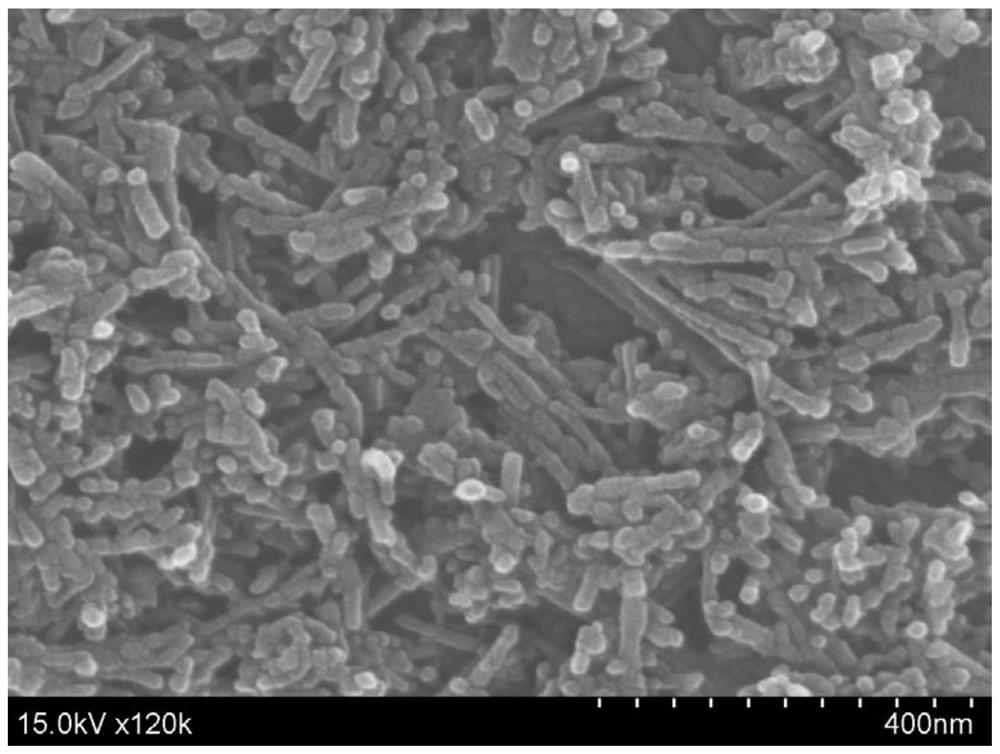

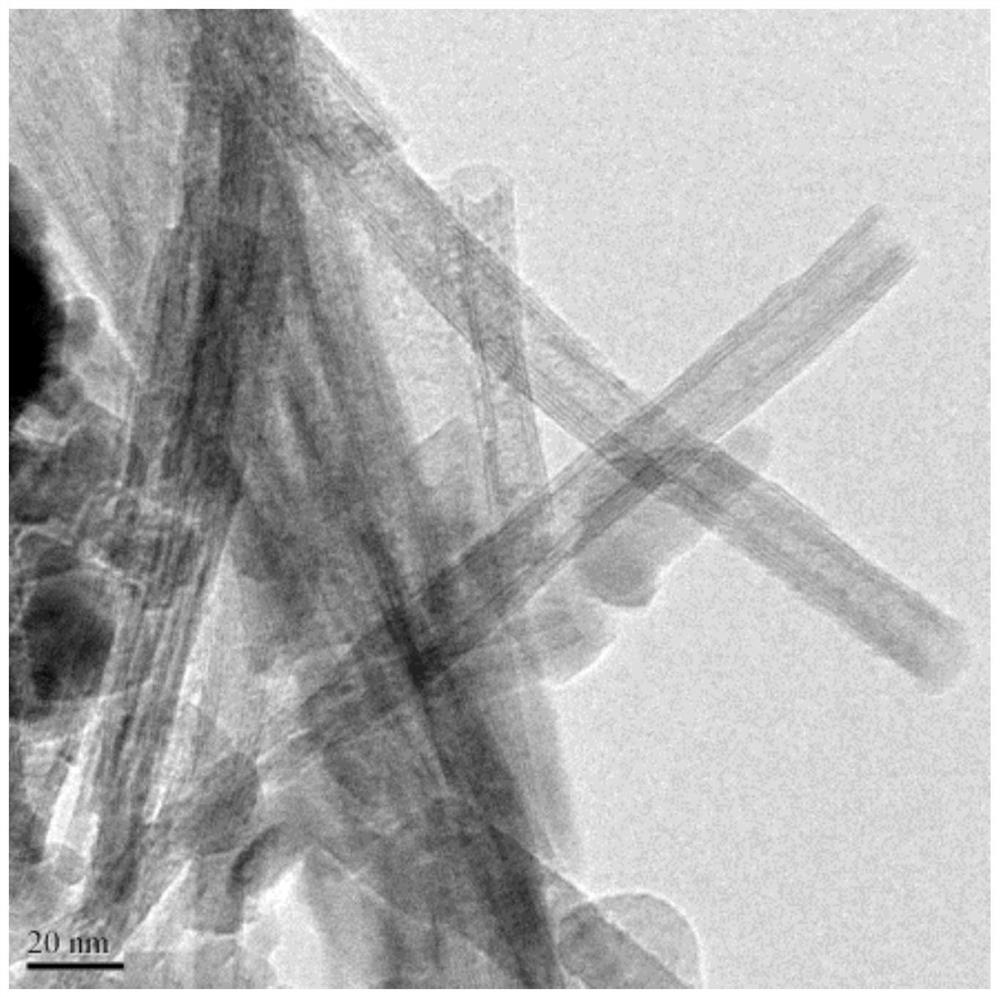

[0049] 2) Preparation of Fe-TiO 2 nanotube

[0050] Weigh 1.3g of prepared TiO 2 Nano powder, add to 30mL 10mol L -1 In the NaOH solution of , add 0.1mL 0.49mol / L Fe to the mixed system 2 (SO 4 ) 3 (Fe ion molar mass is TiO 2 0.6% of ), stirred for 1h, transferred to the autoclave, 150°C hydrothermal reaction for 24h, washed, dried at 80°C for 4h to obtain 0.6% Fe 3+ (Mole percent) Doped modified Fe-TiO 2 nanotube.

[0051] 3) Preparation of g-C 3 N 4

[0052] Weigh 1...

Embodiment 2

[0059] A Fe-TiO 2 Nanotube / g-C3 N 4 Preparation method of composite material:

[0060] 1) Preparation of TiO 2 Nano powder

[0061] Weigh TiCl 4 Add to 3mol / L hydrochloric acid solution to make TiCl 4 The concentration is 0.4mol / L, sonicated for 25min to obtain a light yellow sol, aged at room temperature for 12.5h, washed with water and ethanol respectively, dried at 80°C for 3h, and then calcined at 550°C for 1h to obtain anatase with a particle size of about 30nm Nano-TiO 2 Powder.

[0062] 2) Preparation of Fe-TiO 2 nanotube

[0063] Weigh 0.5g of prepared TiO 2 Nano powder, add to 30mL 10mol L -1 In the NaOH solution, add 0.1mL 0.125mol / L FeCl to the mixed system 3 (Fe ion molar mass is TiO 2 0.2%), stirred for 1.5h, transferred to the autoclave, 140°C hydrothermal reaction for 30h, washed, dried at 80°C for 4h to obtain 0.2% Fe 3+ (Mole percent) Doped modified Fe-TiO 2 nanotube.

[0064] 3) Preparation of g-C 3 N 4

[0065] Weigh 10g of urea, heat up to...

Embodiment 3

[0069] A Fe-TiO 2 Nanotube / g-C 3 N 4 Preparation method of composite material:

[0070] 1) Preparation of TiO 2 Nano powder

[0071] Weigh TiCl 4 Add to 5mol / L hydrochloric acid solution to make TiCl 4 Concentration of 0.45mol / L, ultrasound for 30min to obtain a light yellow sol, aging at room temperature for 13h, washing with water and ethanol respectively, drying at 80°C for 3h, and calcining at 500°C for 2h to obtain anatase-type sol with a particle size of about 30nm Nano-TiO 2 Powder.

[0072] 2) Preparation of Fe-TiO 2 nanotube

[0073] Weigh 2.0g of prepared TiO 2 Nano powder, add to 30mL 10mol L -1 Add 1mL 0.2mol / L Fe(NO 3 ) 3 (Fe ion molar mass is TiO 2 0.8%), stirred for 2 hours, transferred to the autoclave, 150 ° C hydrothermal reaction for 26 hours, washed, dried at 80 ° C for 4 hours to obtain 0.8% Fe 3+ (Mole percent) Doped modified Fe-TiO 2 nanotube.

[0074] 3) Preparation of g-C 3 N 4

[0075] Weigh 10g of urea, heat up to 520°C at a rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com