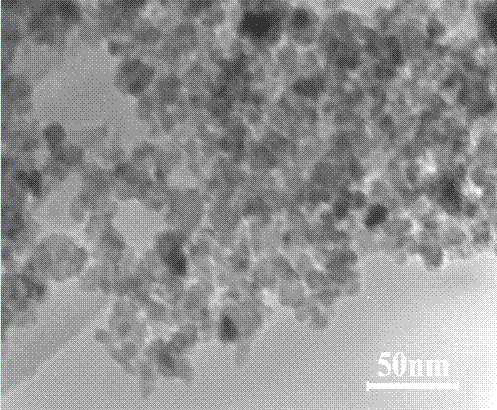

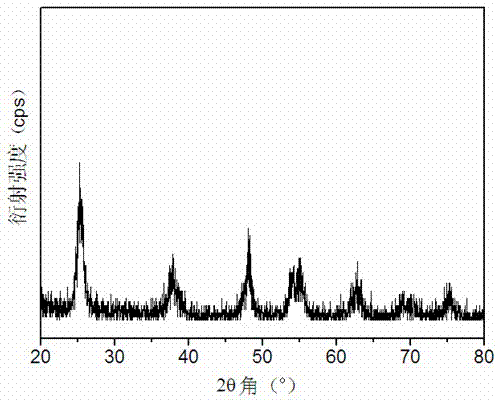

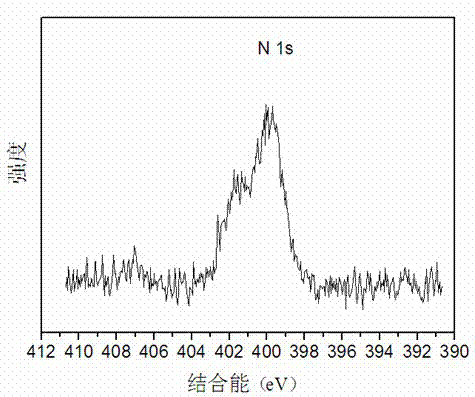

Preparation method for nitrogen and carbon co-doped nanometer titanium dioxide visible-light photocatalyst

A nano-titanium dioxide and photocatalyst technology, applied in the field of photocatalytic materials, can solve the problems of complex preparation process, low yield, high cost, etc., and achieve the effect of simple preparation process, good suspension and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of nitrogen and carbon co-doped nano-titanium dioxide visible light photocatalyst, the specific preparation steps are:

[0026] Step 1, the preparation of ammonium carbonate supersaturated solution

[0027] Add ammonium carbonate and double distilled water into the container, heat to 50°C, and stir to prepare a supersaturated solution of ammonium carbonate;

[0028] Step 2, preparation of precursor solution

[0029] Take glacial acetic acid and add it to the container, add the absolute ethanol solution of tetrabutyl titanate while stirring, continue stirring for 5 minutes after the addition to obtain the precursor solution, and set aside; the added tetrabutyl titanate, absolute ethanol and ice The molar ratio of acetic acid is 1:5:1.

[0030] Step 3, preparation of titanium dioxide xerogel

[0031] Add the precursor solution prepared in step 2 into the reaction device, keep the temperature at 0°C to 20°C, and add the ammonium carbonate supersatur...

Embodiment 2

[0036] Step 1, the preparation of ammonium carbonate supersaturated solution

[0037] Add ammonium carbonate and double distilled water into the container, heat to 50°C, and stir to prepare a supersaturated solution of ammonium carbonate;

[0038] Step 2, preparation of precursor solution

[0039] Take glacial acetic acid and add it to the container, add the absolute ethanol solution of tetrabutyl titanate while stirring, continue stirring for 30 minutes after the addition to obtain the precursor solution, and set aside; the added tetrabutyl titanate, absolute ethanol and ice The molar ratio of acetic acid is 1:20:2.

[0040] Step 3, preparation of titanium dioxide xerogel

[0041] Add the precursor solution prepared in step 2 into the reaction device, keep the temperature at 0°C to 20°C, and add the ammonium carbonate supersaturated solution prepared in step 1 while stirring, so that a white precipitate appears, and the ammonium carbonate supersaturated solution Add the...

Embodiment 3

[0045] Step 1, the preparation of ammonium carbonate supersaturated solution

[0046] Add ammonium carbonate and double distilled water into the container, heat to 50°C, and stir to prepare a supersaturated solution of ammonium carbonate;

[0047] Step 2, preparation of precursor solution

[0048] Add glacial acetic acid into the container, add tetrabutyl titanate absolute ethanol solution while stirring, continue stirring for 20 minutes after the addition to obtain the precursor solution, and set aside; the added tetrabutyl titanate, absolute ethanol and ice The molar ratio of acetic acid is 1:15:3.

[0049] Step 3, preparation of titanium dioxide xerogel

[0050] Add the precursor solution prepared in step 2 into the reaction device, keep the temperature at 0°C to 20°C, and add the ammonium carbonate supersaturated solution prepared in step 1 while stirring, so that a white precipitate appears, and the ammonium carbonate supersaturated solution Add the amount so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com