Method for synergetically treating organic waste liquid and heavy-metal waste liquid by supercritical water

A technology of organic waste liquid and synergistic treatment, applied in chemical instruments and methods, heating water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of reducing the concentration of pollutants, and achieve the effect of efficient and rapid treatment and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

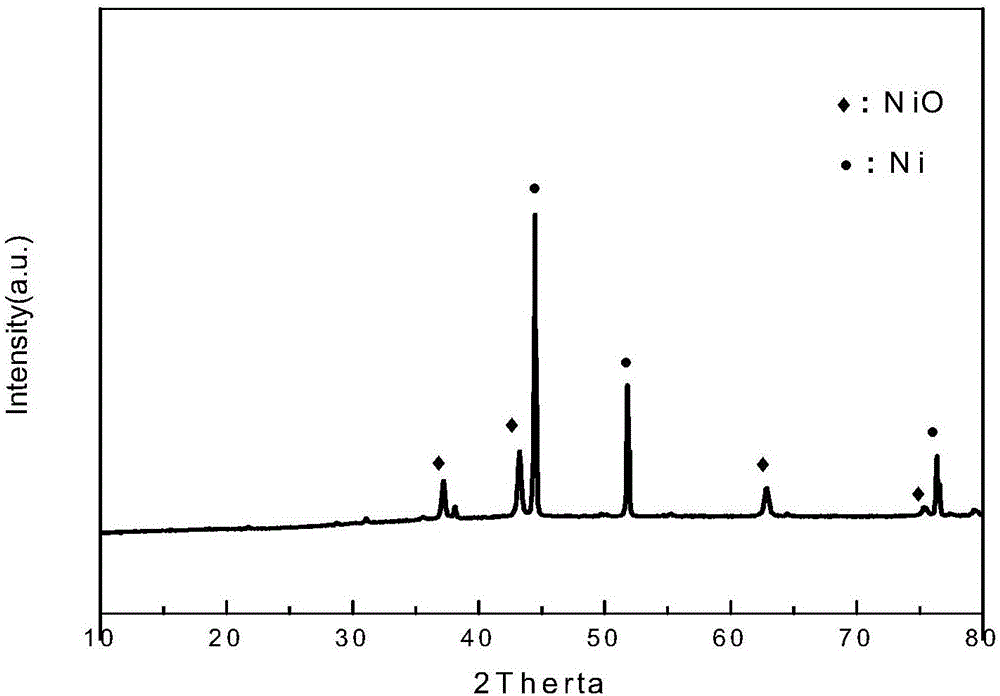

[0015] Embodiment 1: first, the depolymerized residue of corn stalk after 0.1g drying (element mass percent is carbon 45%, oxygen 48%, hydrogen 6%, nitrogen and sulfur add up to 1%) add reactor, then add 1mL concentration 2.5 mol / L containing Ni(NO 3 ) 2 Heavy metal waste liquid, make the material and heavy metal waste liquid mix evenly, and finally seal. Before heating, argon gas was passed into the reactor twice and then evacuated to remove the air inside. Afterwards, the reactor was heated from room temperature to 650°C at a heating rate of about 30°C / min. The reaction was maintained at 650±5°C and 22.5-26MPa for 30min. After the reaction, it was cooled to 300° C. at room temperature, and then water-cooled to normal temperature. Collect the gas for component analysis, then measure the flow rate with a gas flow meter, then open the reactor, separate the liquid and solid, and weigh them separately for analysis. Experimental results show that the gasification rate of corn...

Embodiment 2

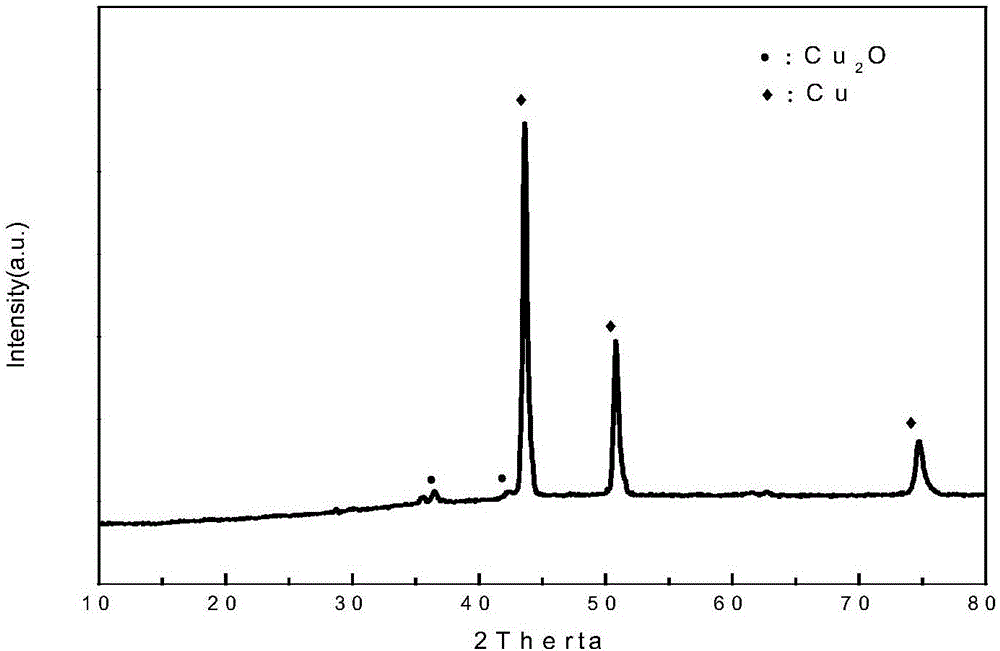

[0016] Example 2: Add 0.1 g of dried corn stalk depolymerization residue (element mass percentage is carbon 45%, oxygen 48%, hydrogen 6%, nitrogen and sulfur total 1%) to the reactor, and then add 1 mL concentration of 2.5 moles / L containing Cu(NO 3 ) 2 Heavy metal waste liquid, make the material and heavy metal waste liquid mix evenly, and finally seal. Before heating, argon gas was passed into the reactor twice and then evacuated to remove the air inside. Afterwards, the reactor was heated from room temperature to 650°C at a heating rate of about 30°C / min. The reaction was maintained at 650±5°C and 22.5-26MPa for 30min. After the reaction, it was cooled to 300° C. at room temperature, and then water-cooled to normal temperature. Collect the gas for component analysis, then measure the flow rate with a gas flow meter, then open the reactor, separate the liquid and solid, and weigh them separately for analysis. Experimental results show that the gasification rate of corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com