Methanation technology

A methanation and process technology, applied in the field of methanation process, can solve the problems of over-reaction temperature, complicated temperature control and adjustment measures, increased energy consumption, land occupation and operation cost, etc., so as to avoid over-reaction temperature, save energy and reduce consumption , The effect of simplifying the process flow and system control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

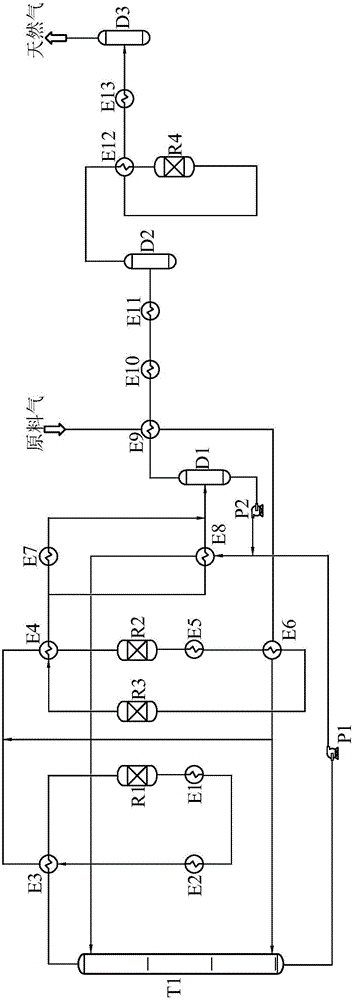

[0016] Such as figure 1 Shown, this methanation process method is as follows:

[0017] The temperature of the fresh raw gas after desulfurization is 30°C, the pressure is 3.17MpaG, the content of CO is 17.14%, and the content of H 2 Content 56.87%, CO 2 The content is 25.55%, and the flow rate is 30648kmol / h; it enters the ninth heat exchanger E9 and the sixth heat exchanger E6 in order to exchange heat to 255 °C and then divides into two streams, that is, the first raw material gas with a volume ratio of 65:35 and the second Shares of raw gas.

[0018] Wherein the first raw material gas enters the bottom of the saturated hot water tower, and the first raw material gas is humidified and replenished; in the material from the top of the saturated hot water tower (H 2 O+CO 2 ) / (CO+H 2 )=1.12 (volume ratio).

[0019] The tower bottom liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com