Synthesis method for pharmaceutically acceptable salt of alkylhydrazine

A synthesis method and technology of alkyl hydrazine, which are applied in hydrazine preparation, organic chemistry and other directions, can solve the problems of high industrial scale-up cost, difficult scale-up production, large amount of waste water, etc., and achieve the effects of low cost, short synthesis route and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

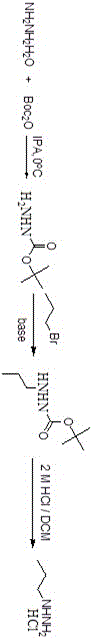

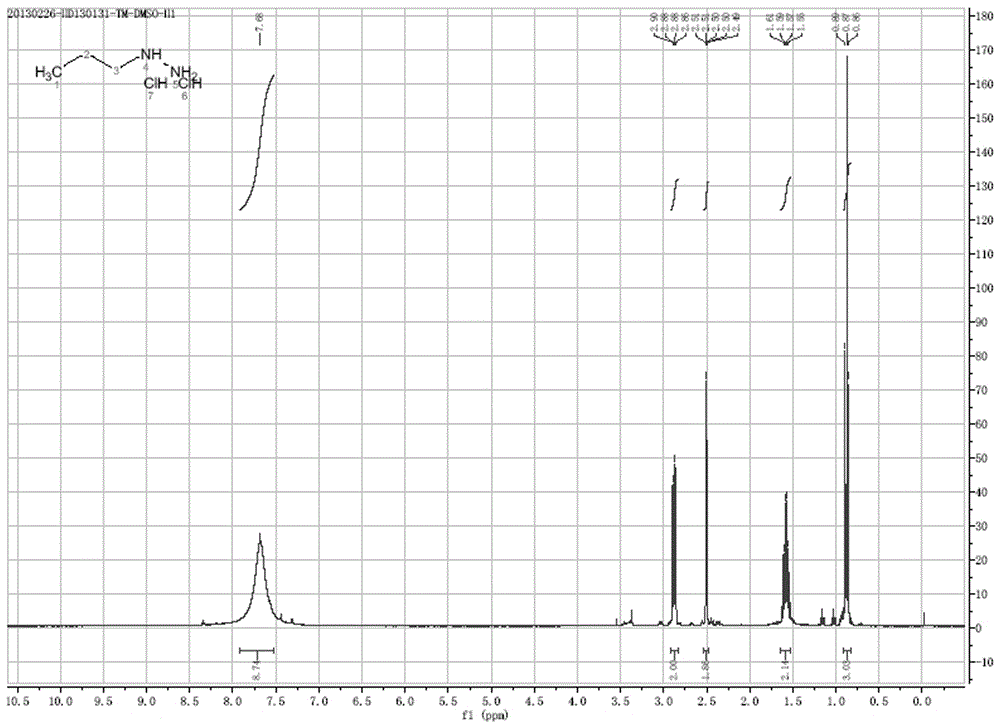

[0035] Example 1 Synthesis of n-propylhydrazine hydrochloride, see the synthetic route figure 1 , Including the following steps:

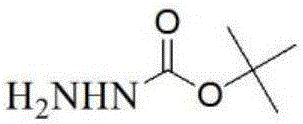

[0036] (1) Synthesis of BOC hydrazine: dissolve the raw material hydrazine hydrate in the isopropanol (IPA) solvent, the volume-weight ratio (ml / g) of isopropanol to the hydrazine hydrate is 5-20:1, and then add Add BOC anhydride to the solution, the molar ratio of hydrazine hydrate and BOC anhydride is 1~1.5:1~2:1, stir at 0℃ until the reaction is complete (about 0.5h), concentrate under reduced pressure until the solvent is clear, dichloromethane Dilute, dry with anhydrous sodium sulfate, and concentrate under reduced pressure to obtain a white solid. The white solid is slurried with petroleum ether, and the volume-weight ratio of the petroleum ether to the white solid is 5-10:1, and then the BOC hydrazine is obtained by vacuum filtration with a yield: 50%;

[0037] (2) Synthesis of BOC n-propyl hydrazine: Add the BOC hydrazine obtained in step (1) a...

Embodiment 2

[0039] Example 2: Synthesis of BOC Hydrazine:

[0040] Add 30 g of hydrazine hydrate and 150 ml of isopropanol to a three-necked reaction flask with a stirrer, add 60 ml of an isopropanol solution of 55.8 g of BOC anhydride under ice-water bath cooling, and stir for 0.5h at 0-10°C until the reaction is complete , Concentrate until the solution is clear, add 100 ml of dichloromethane, dry with anhydrous sodium sulfate, and concentrate under reduced pressure to obtain a white solid. The obtained crude product was slurried with 200 ml of petroleum ether and filtered under reduced pressure to obtain 35.7 g of white solid, with an LC purity of over 92% and a yield of 50%.

Embodiment 3

[0041] Example 3: Synthesis of BOC Hydrazine

[0042] Add 30 g of hydrazine hydrate and 150 ml of isopropanol to a three-necked reaction flask with a stirrer, add 120 ml of isopropanol solution of 111.6 g of BOC anhydride under ice-water bath cooling, and stir at 0-10℃ for 0.5h until the reaction is complete , Concentrate until the solution is clear, add 100 ml of dichloromethane, dry with anhydrous sodium sulfate, and concentrate under reduced pressure to obtain a white solid. The obtained crude product was slurried with 200 ml of petroleum ether and filtered under reduced pressure to obtain 35.7 g of white solid, with an LC purity of more than 55% and a yield of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com