PSP thermosetting polystyrene board

A PSP, thermosetting technology, applied in the field of building waterproof and thermal insulation engineering boards, can solve the problems of not meeting the standard requirements, consumer safety hazards, fire hazard losses, etc., and achieve the effect of improving the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

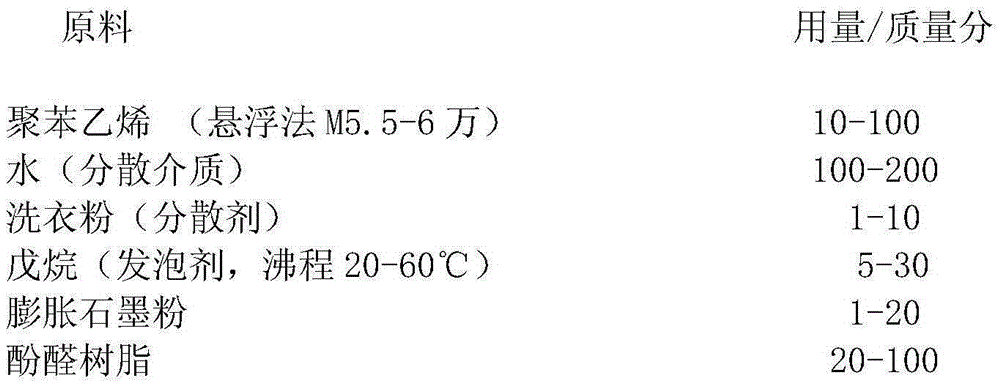

[0025] (1) PSP thermosetting polystyrene board:

[0026]

[0027] The above quality scores total 300%

[0028] (2) Process flow:

[0029] polystyrene

[0030] Foaming agent→pre-foaming→adding graphite and phenolic resin→curing→molding→cooling→foam products

[0031] Dispersant

[0032] (3) Key points of process operation:

[0033] ①Feeding Add the screened beads from the hopper, pass through the fan and cyclone feeder, and enter the kettle from the hopper of the reaction kettle. The dispersant soap powder is pre-dissolved in the dissolving pot and then sent to the reaction kettle, and a certain amount of water is added, and then the agitator is started to stir evenly. Finally, use a reciprocating pump to feed the foaming agent into the kettle through the high-level metering tank.

[0034] ②Impregnation, absorption and feeding are completed, and the jacket is passed through the reaction kettle to heat up the temperature. At this time, the foaming agent accelerates the v...

Embodiment 2

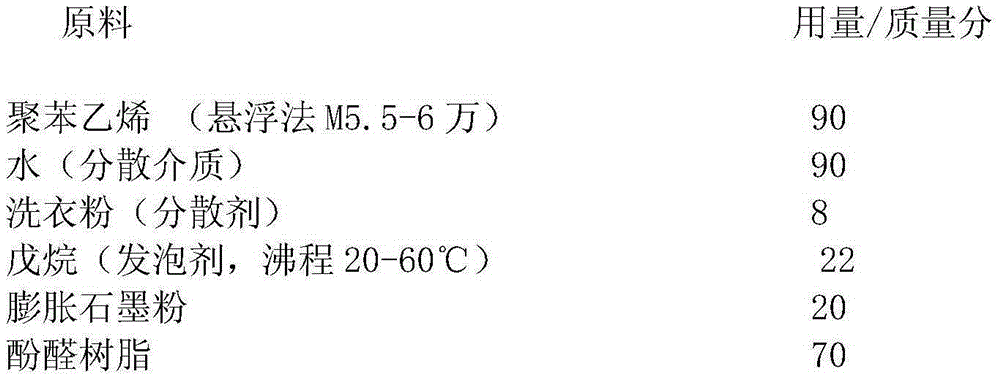

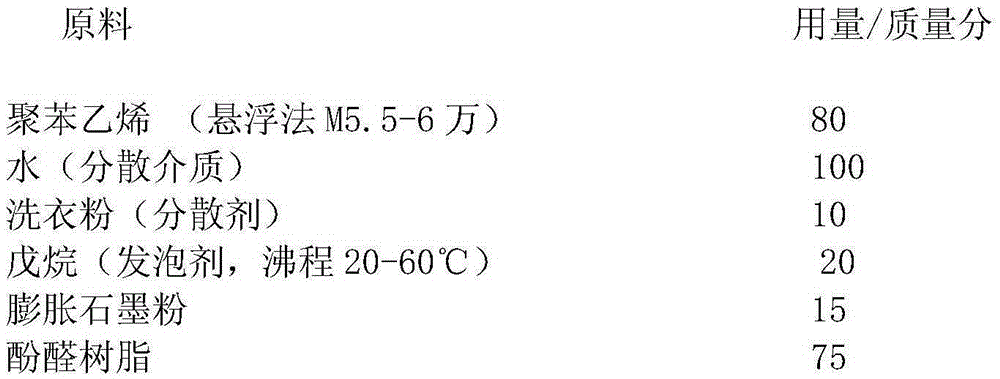

[0040] (1) PSP thermosetting polystyrene board:

[0041]

[0042] The above quality scores total 300%

[0043] (2) Process flow:

[0044] polystyrene

[0045] Foaming agent→pre-foaming→adding graphite and phenolic resin→curing→molding→cooling→foam products

[0046] Dispersant

[0047] (3) Key points of process operation:

[0048] ①Feeding Add the screened beads from the hopper, pass through the fan and cyclone feeder, and enter the kettle from the hopper of the reaction kettle. The dispersant soap powder is pre-dissolved in the dissolving pot and then sent to the reaction kettle, and a certain amount of water is added, and then the agitator is started to stir evenly. Finally, use a reciprocating pump to feed the foaming agent into the kettle through the high-level metering tank.

[0049] ②Impregnation, absorption and feeding are completed, and the jacket is passed through the reaction kettle to heat up the temperature. At this time, the foaming agent accelerates the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com