Dyeing and finishing method of seaweed fiber fabric

A seaweed fiber and fabric technology, applied in the field of dyeing and finishing, can solve the problems of seaweed fiber function damage, uneven dyeing effect of dyeing and finishing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

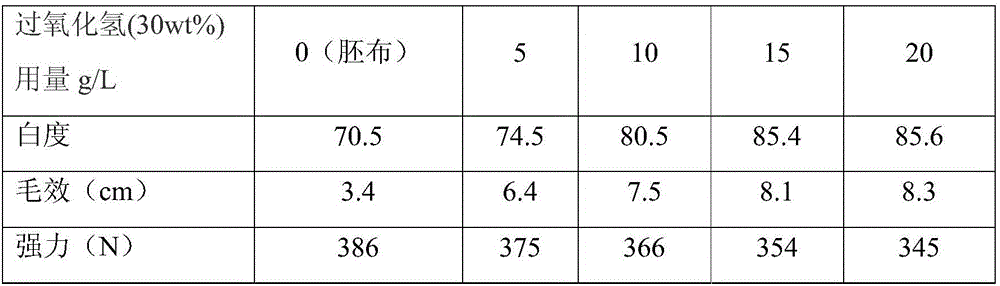

[0035] This embodiment is the specific operation steps and method of the pretreatment process of descouring and bleaching.

[0036] The equipment used is a continuous refining machine, which is generally divided into 5 to 6 independent tanks, and different additives can be added to each tank, and the temperature can also be adjusted. In the process of descouring and bleaching pretreatment using this equipment, the first two tanks are combined with enzyme desizing and refining process, the third tank is used for pH adjustment, the fourth tank is washed with water, and the last two tanks are used for bleaching process and water washing and adjustment. pH.

[0037] Due to the low strength of single fiber of seaweed fiber, low tension is selected for tension to avoid damage to fiber strength, bio-enzyme desizing process is selected, and low alkalinity bleaching process is selected for bleaching. The refining agent is mainly used for refining natural fibers, which can be used accor...

Embodiment 2

[0062] Example 2

[0063] Loose heat setting is adopted during pre-setting, the heat setting temperature is 110-130°C, and the vehicle speed is 20-30m / min.

[0064] More specifically, in this embodiment, the presetting temperature is 120°C.

Embodiment 3

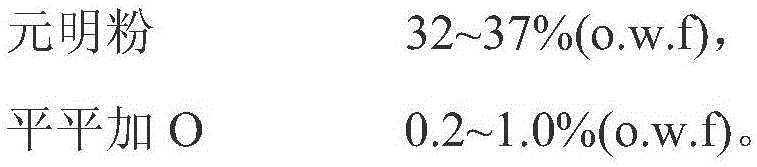

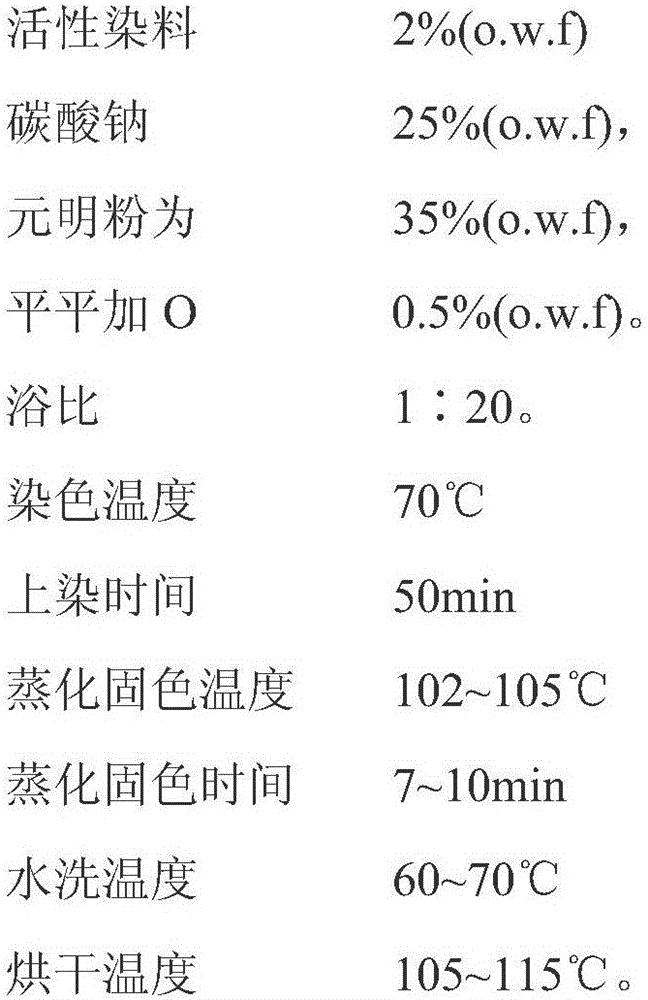

[0066] The reactive dyeing process includes the following steps:

[0067] Dyeing→steaming and color fixing→washing→drying;

[0068] in:

[0069]

[0070] In the dyeing process, the bath ratio is 1:(15-25), the dyeing temperature is 60-80°C, and the dyeing time is at least 50 minutes.

[0071] In the steaming color fixing process, the steaming color fixing temperature is 100-110°C; the steaming color fixing time is 5-15 minutes.

[0072] In the water washing process, the washing temperature is 50-80°C. The drying temperature in the drying process is 100-120°C.

[0073] Specifically in this embodiment:

[0074]

[0075] In the embodiment of the present invention, o.w.f refers to the addition amount of other substances calculated based on the total mass of the seaweed fiber fabric. In this embodiment, Pingpingjia O is Pingpingjia O-25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com