Double-core cable for aviation and manufacturing method thereof

A dual-core optical cable, aerospace technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of optical fiber and outer sheath material performance degradation, optical cables cannot meet the application occasions, and cannot guarantee the operation of optical cables, etc., to achieve high resistance to high Low temperature resistance, excellent creep resistance, and the effect of solving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

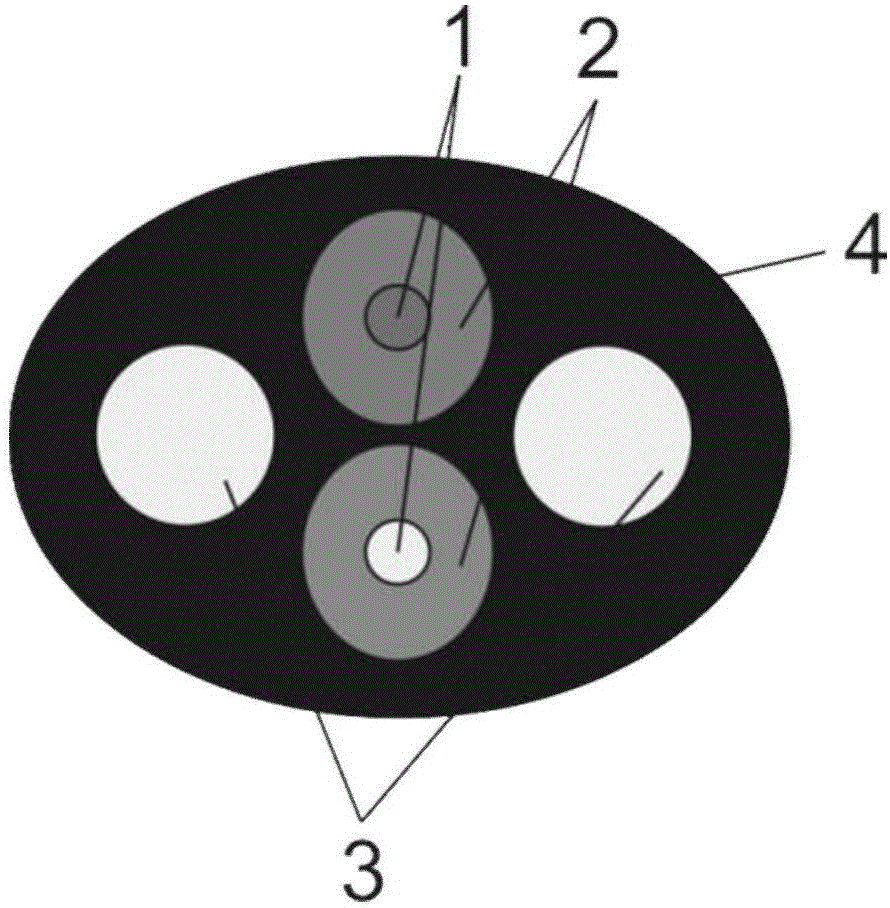

[0036] A dual-core optical cable for aerospace, with a structure such as figure 1 As shown, the double-core optical cable includes two side-by-side optical fibers, the outer surface of each optical fiber is coated with a polyimide coating, and a polyethersulfone tight sleeve layer 2 is provided outside the polyimide coating. Two aramid fiber reinforced optical cable reinforcement cores (KFRP) 3 are arranged on both sides of the optical fiber. The outer sheath 4 is arranged on the periphery of the core 3 (KFRP); the polyimide coating is obtained by coating polyimide on the outer surface of the optical fiber, and then curing by ultraviolet rays, the coating speed is 180m / min, and the ultraviolet The wavelength is 380nm.

[0037] The thickness of the polyimide coating is 37 μm. The thickness of the polyethersulfone tight sleeve layer is 0.15mm, the thickness of the outer sheath is 0.45mm, and the material of the outer sheath is thermoplastic polyurethane elastomer (TPU). The r...

Embodiment 2

[0045] A kind of twin-core optical cable for aerospace, as shown in embodiment 1, the difference is:

[0046] The double-core optical cable includes two side-by-side optical fibers, and the outer surface of each optical fiber is coated with polyimide coating. The polyimide coating is coated with polyimide on the outer surface of the optical fiber, and then passed through ultraviolet After curing, the coating speed is 150m / min, and the ultraviolet wavelength is 375nm.

[0047] The thickness of the polyimide coating is 42 μm. The thickness of the polyethersulfone tight sleeve layer is 0.18mm, the thickness of the outer sheath is 0.38mm, and the material of the outer sheath is thermoplastic polyurethane elastomer (TPU).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com